IO-Link with Bihl+Wiedemann: Easy, Flexible & Cost-efficient

IO-Link devices are nowadays common in machines and systems. This is because IO-Link allows sensors and actuators to be connected to the control level via a cost-effective point-to-point connection. Find out more about IO-Link and the associated advantages here.

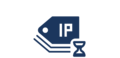

This page mainly deals with the following question: What is the best way to integrate IO-Link? Bihl+Wiedemann offers you a sophisticated concept for this: IO-Link can be embedded perfectly in ASi-5and our user-friendly PC software – from the device to the PLC or cloud. Our solution provides more benefits than just freedom of topology, reduced wiring complexity without switches, and a smart power supply concept. Other advantages include reduced IP management complexity and low-cost IO-Link masters, which we provide with 1, 2, 4 and 8 ports. Numerous technical features also enable you to commission IO-Link devices with maximum convenience. For us, one thing is certain: There is no smarter and more economical way to integrate IO-Link.

Advantages at a glance

Extremely Simple Commissioning

IO-Link masters can be easily integrated using our convenient configuration tool. For example, you can easily open the IODD and get graphical support for the parameterization of IO-Link devices. Live device parameterization gives you direct control over the settings while being online.

Automatic Parameterization when Replacing Devices

Our PC software makes it easy to copyandreuse parameters from IO-Link devices. This applies both within projects and across various projects. The copy function saves a lot of time and reduces parameterization errors, especially when using many IO-Link devices.

Integrated

IT interfaces

All our ASi-5/ASi-3 Gateways have an OPC UA server and a REST API as IT interfaces. This enables seamless integration into IT systems, such as cloud-based databases. Process, parameter, and diagnostic data from the IO-Link devices can therefore be transferred easily and cost-effectively to the cloud or HMI – a prerequisite for modern systems in the age of Industry 4.0.

Smart

Wiring Concept

The amount of effort required for wiring is reduced because all nodes – IO-Link devices, standard sensors and safety modules – are connected to an unshielded 2-core cable using piercing technology. Because no connectors are required, you also save costs and valuable resources. Besides, the maximum IO-Link cable length of 20 meters plays a secondary role in our case because you can distribute the IO-Link masters anywhere on the AS-Interface cable with up to 200 meters in length.

Smart

Energy Distribution

In round cable solutions, the respective connector indirectly determines the "limit" for individual IO-Link masters and for the total current of all IO-Link masters connected in series. With ASi, no loop-through from module to module is needed . The AUX supply is done over reverse polarity protected profile cables, so each IO-Link master draws its energy individually – at 20 A per AUX cable.

Full

Flexibility

While common IO-Link masters are only available from 4 ports or more, ASi also offers the possibility to efficiently integrate 1- or 2-port IO-Link masters. This means that even distributed individual IO-Link devices can be perfectly integrated and no resources are wasted in terms of sustainability. You also enjoy great freedom in the choice of topology and can implement a star, ring, line and network structure, for example. You also gain maximum flexibility through the fieldbus independence of our IO-Link masters.

Reduced

Overall Costs

Our IO-Link masters with 4 ports are, for instance, about 50 % cheaper than comparable modules from other manufacturers. This means that the costs for our gateway are recovered, for example, from just 3 IO-Link masters with 4 ports each. You also reduce your installation workload and benefit from the elimination of switches and pre-assembled cables. Click here to view our main cost comparison.

The IO-Link master is integrated as an ASi node into the ASi network

IO-Link devices can be integrated into the ASi network along with standard sensors, standard actuators and safety components

All process data (up to 32 bytes per port) of the IO-Link devices is available via the cyclic ASi communication.

All IO-Link parameters can be conveniently adjusted through the B+W Software Suite or acyclically via the control system

Diagnostic information from IO-Link available via ASi

Our IO-Link masters can be optimally combined with IO-Link devices from any manufacturer

If an IO-Link device needs to be replaced, its parameters are stored in the IO-Link master and are transferred automatically to the new one.

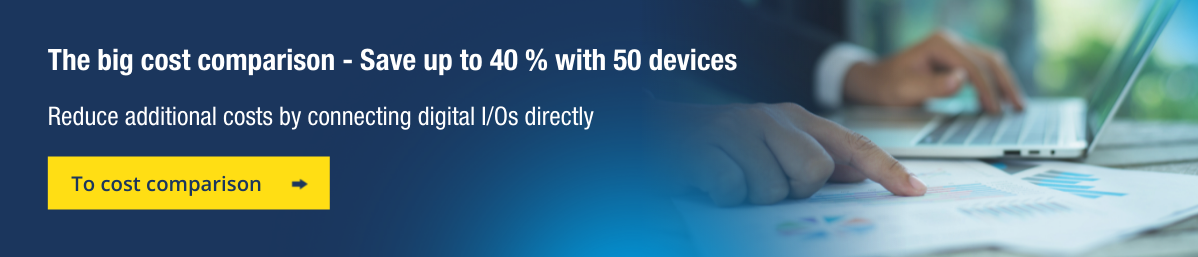

IO-Link Safety Solutions from Bihl+Wiedemann

IO-Link Safety is an extension of IO-Link. There is an additional safety communication layer on the master and device side. These become the "Fail-Safe (FS) master" and "Fail-Safe (FS) device". Bihl+Wiedemann is in the process of developing its own "FS master". IO-Link is already a perfect match for the safety components of Bihl+Wiedemann.

Reduced machine-related costs

A cost-efficient standard cable establishes a connection up to 20 meters long between the IO-Link master and IO-Link device.

High machine availability

Downtimes are reduced because when a defective IO-Link device is replaced, its parameters are automatically transferred to the new sensor by the IO-Link master or control system.

Efficient operation

IO-Link devices can be positioned in the machine directly at the work site. These do not have to be accessible for parameterization.

Demand-oriented maintenance

Continuous diagnostic data of the entire process lengthen maintenance intervals, since systems and machines need to be maintained much less frequently due to the automatic readjustment via IO-Link

It is possible to extend existing bus systems. As a prerequisite, the system mapping of IO-Link for the respective bus system must be already implemented. It is particularly easy to use IO-Link in conjunction with the ASi intelligent wiring system. Thanks to piercing technology, corresponding IO-Link masters can be easily retrofitted where they are needed.