Muting

Muting With AS-Interface – Cost-Effective, Easy, Flexible

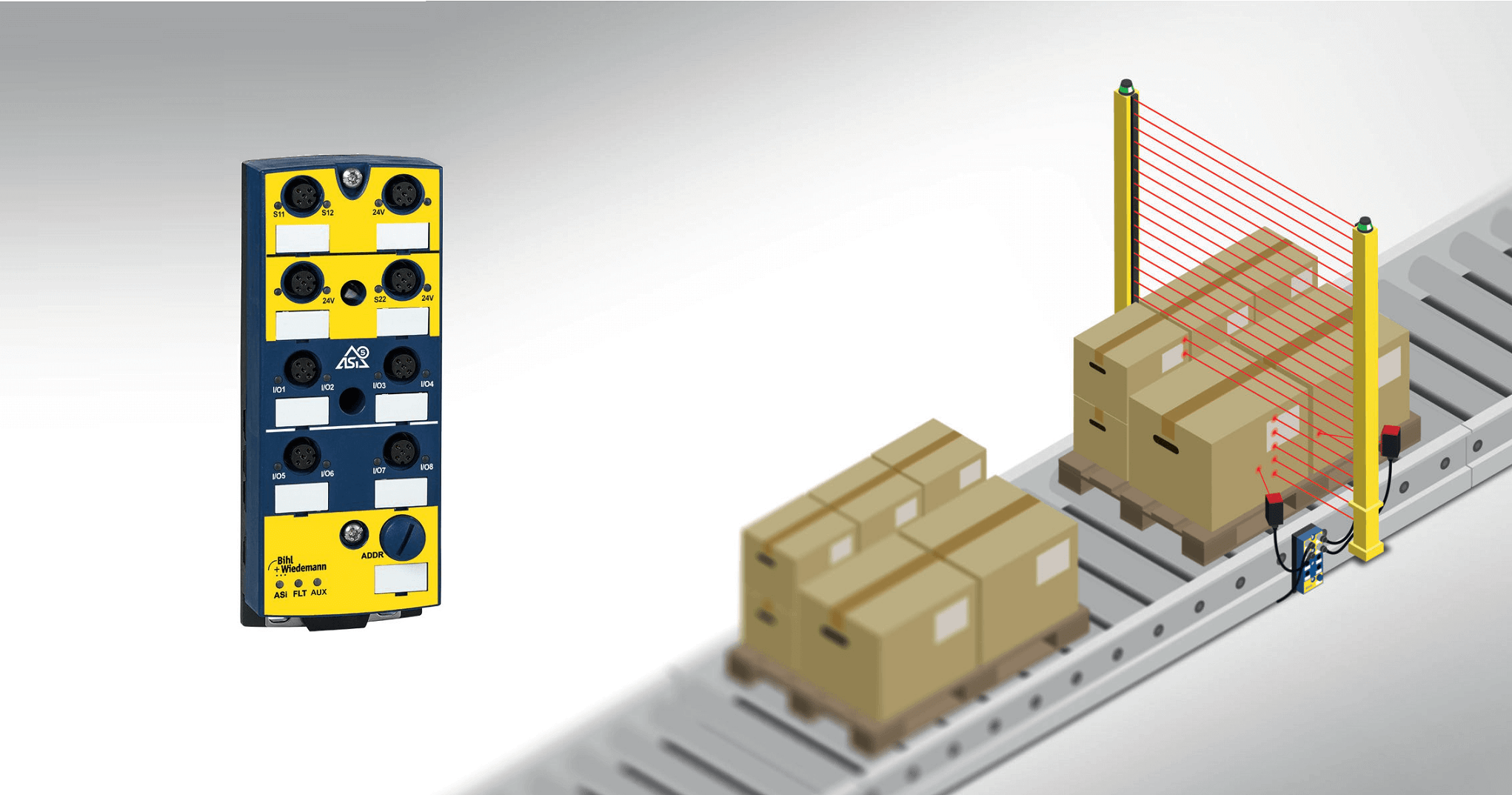

Using AS-Interface as a bus system, it is possible to implement muting applications up to SIL3/PLe easily and efficiently. Thanks to ASi-5 Safety, you can now realize cross-muting and sequential muting far more cost-effectively than with comparable Ethernet-based solutions. Our new, compact ASi-5 Safety Muting Module processes all signals required for muting. Ready-certified muting modules can be configured quickly and easily.

We also offer a solution for widely dispersed sensors: our active distributors capture the signals where they occur. All of Bihl+Wiedemann's muting solutions allow you to benefit from the proven advantages of ASi: Free choice of topology, extremely easy installation thanks to piercing technology as well as drastically reduced cable use. Find out here why AS-Interface is a resource-saving technology.

Contents

- Muting With AS-Interface – Cost-Effective, Easy, Flexible

- One Module for All Signals

- What is Muting?

- Advantages of the ASi-5 Safety Muting Module

- Muting with Active Distributors

- Installation in Cable Duct

- Drag & Drop Makes Configuration Simple

- Simple Muting – all Needed Signals in One Single Module

- Advantages of Bihl+Wiedemann Muting Modules

- The New ASi Safety I/O Modules in Detail

What is Muting?

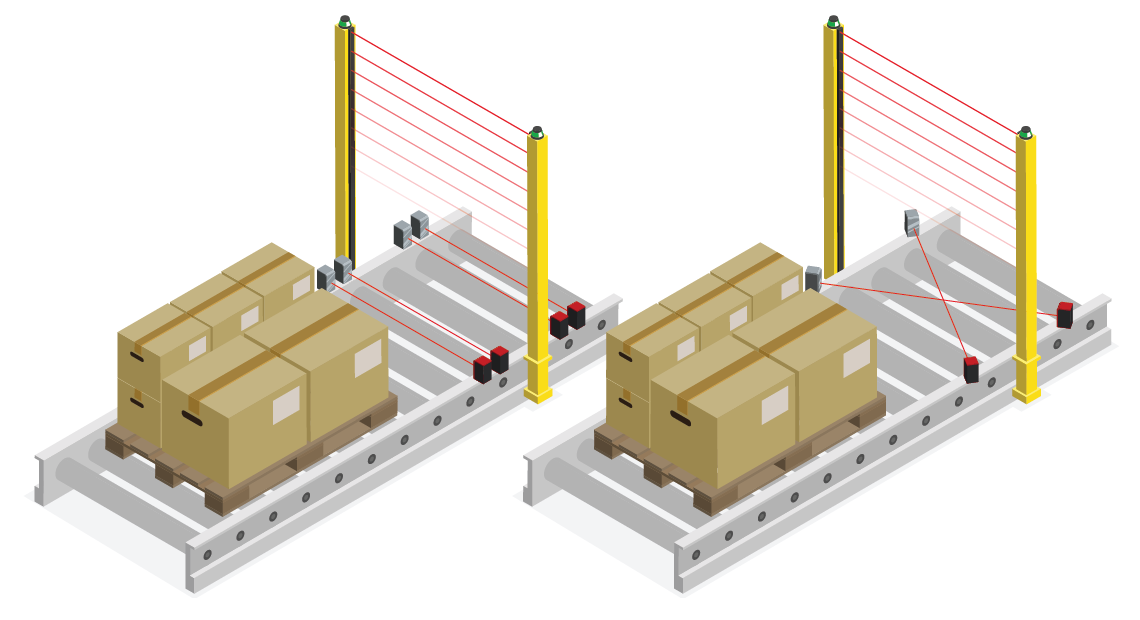

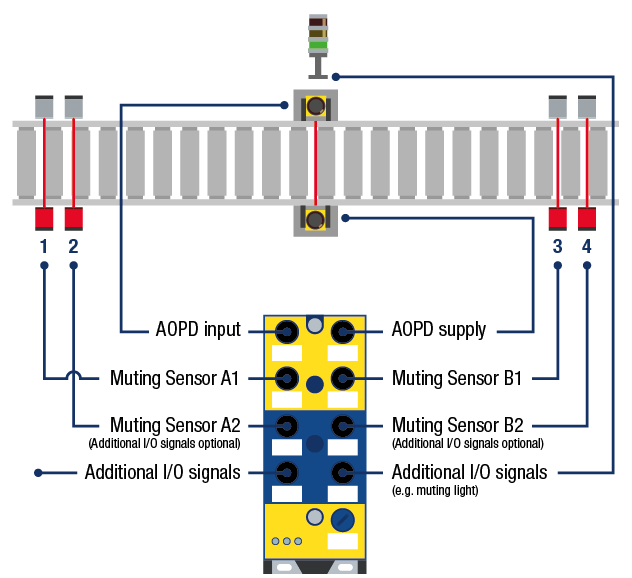

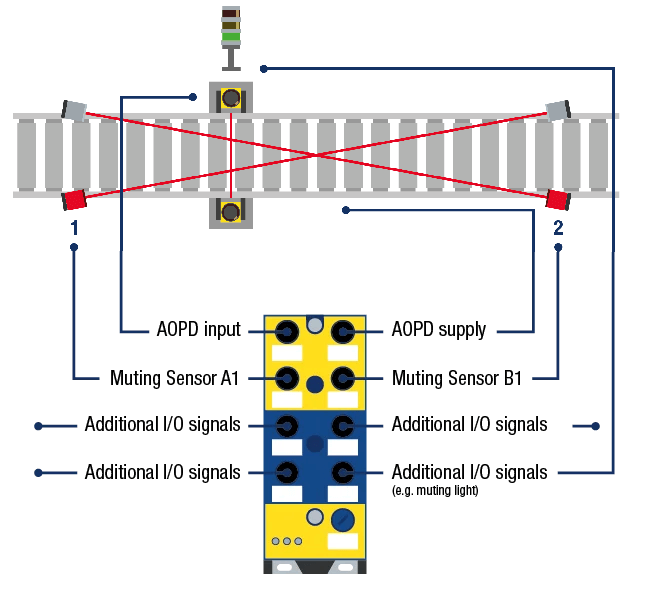

Muting refers to the momentary bypassing of electro-sensitive protective equipment. This could be, for example, a light barrier or light curtain. The distinction between expected materials and unexpected objects or persons is made using corresponding muting sensors. When arranging the muting sensors, a distinction is made between cross-muting and sequential muting. ASi as a bus system makes it possible to easily, efficiently and cost-effectively implement the various muting arrangements. Both muting arrangements can be conveniently parameterized using the PC software.

The arrangement of the two sensors with cross muting is crossed. They must both be activated simultaneously to initiate the muting cycle.

With a sequential arrangement, multiple sensors are connected one after the other; they must be activated or deactivated consecutively in a certain sequence.

Full

Flexibility

All signals in one module. The modules can be connected flexibly, whether for cross-muting or sequential muting. Unused inputs and outputs can be used for other applications. Alternatively to processing the relevant signals in the Safety Monitor, they can also be forwarded via PROFIsafe, CIP Safety, FSoE, or openSAFETY.

Easy

Parameterization

Using our Bihl+Wiedemann Software Suite, ready-certified muting devices can be configured quickly and easily for many applications. This way, it is possible to make further setting options, such as "End muting when the light barrier is released," "Tolerated interruption time," "Belt stop" and timing parameters. No complex programming in the control system is required.

- Cost-efficient solution for cross-muting and sequential muting with many inputs and outputs

- All signals required for muting in just one module using one ASi-5 address

- Convenient parameterization via the PC software with a certified muting building block

- For example, unassigned inputs and outputs can be used to control muting lamps and motors or to integrate push button modules

- All relevant signals can be preprocessed in the Safety Monitor or optionally forwarded via PROFIsafe, CIP Safety, FSoE or openSAFETY

Muting with Active Distributors

When it comes to muting the important thing is to consider the individual requirements in advance. It doesn't always make sense to bring all the signals to one point – for example when the sensors are too distant from each other. Bihl+Wiedemann also offers appropriate solutions for such applications – for example where active splitters are used. These collect the signals where they arise. All required signals can then be integrated via drag & drop in the PC software.

The Active Distributors in Detail

- Connection of any sensors and actuators

- Safety and standard ASi node

- Make standard sensors and actuators ASi compatible

- Up to protection class IP67

- On M12, M8, push-in terminals or connecting wires

- Round cable length: 0.25 m, 0.6 m, 2 m, 5 m, or according to customer requirements

Functional Safety

Learn how to seamlessly integrate safe sensors and actuators as well as safety monitors into all common automation systems with ASi Safety. Safe and unsafe signals can be transmitted on the same line.

PLC Independent Safety Technology

Discover the advantages of our safety and wiring technology, which is system and manufacturer-neutral. In this way, it enables simple, fast and thus cost-effective commissioning.

Selection of Mode of Safe Operation

Read all about how our TÜV-certified device facilitates "selection of mode of sfae operation selection": A standard HMI allows you to safely select up to 5 different operating modes for a maximum of 6 plant sections – each with unique safety functions.

Speed Monitoring

Discover an effective way to safely evaluate sensors or rotary encoders by means of our speed monitors. For example, a safe reduced speed can be achieved for setup operation.