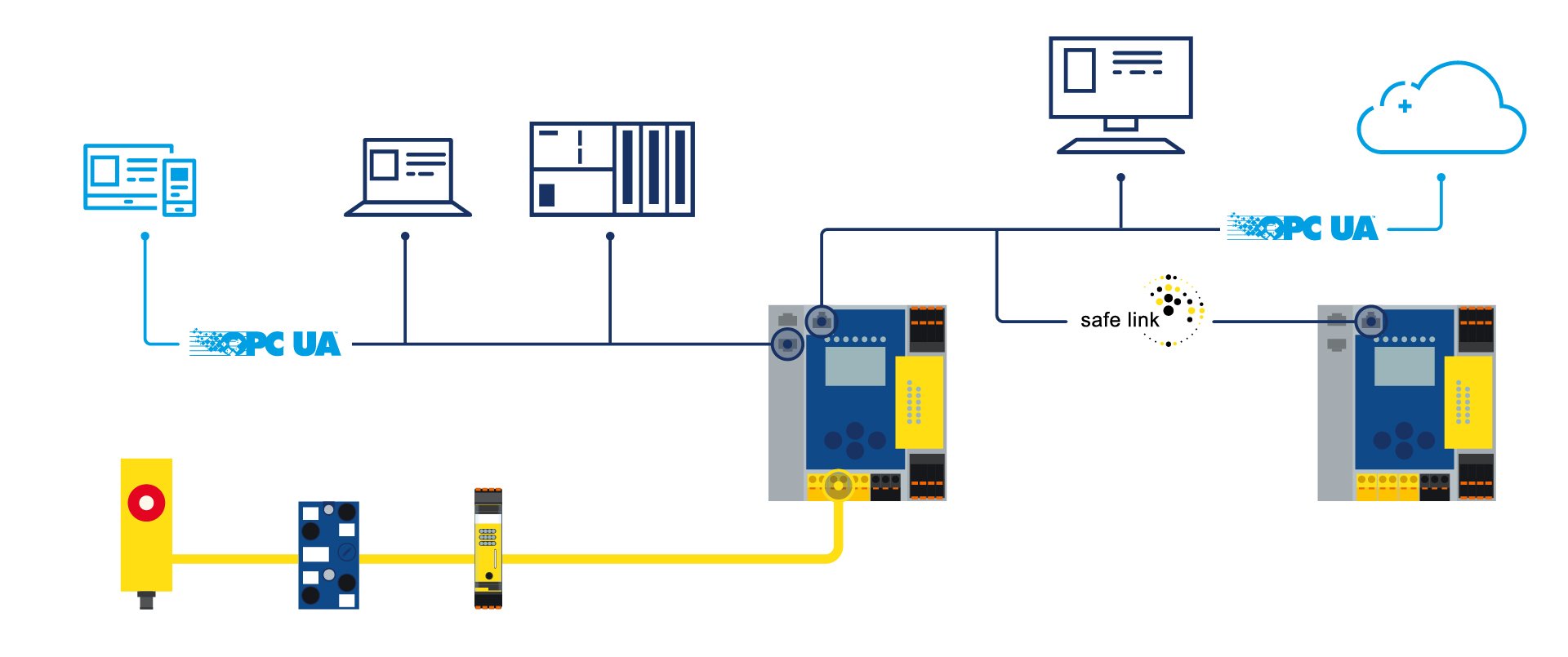

OPC UA – Universal data exchange from the sensor to the cloud

How can the data from intelligent sensors be transferred to the IT level for further processing? This is an important question – because only those who are able to do so can successfully implement Industry 4.0 projects or predictive maintenance. Our answer is OPC UA: Many Bihl+Wiedemann gateways feature this open communication protocol. This enables them to transfer the data from the IO-Link sensors directly upstream to the IT world. This data-flow would not be so easily accessible without OPC UA because IO-Link devices do not have any direct TCP/IP connection.

Easy access to a wide range of machine data

By using the OPC UA server in our gateways you can also access a wide range of machine data. A lot of information about the machine and the process, from device diagnostics to process data, can be easily retrieved via the network. Another advantage: By using OPC UA, there is a noticeable reduction of load on the controller and fieldbus.

To ensure data security, we support, among other things, encrypted OPC UA communication even with customer-specific certificates. This allows the devices to be seamlessly integrated into existing IT security concepts.

Interested in further information about OPC UA solutions by Bihl+Wiedemann? Just contact us!

Fig.: OPC UA ensures direct data exchange between all connected devices – regardless of the fieldbus.

Your advantages with OPC UA solutions by Bihl+Wiedemann

- Easy retrieval of collected data to the cloud, on a local server or even on a visualization tool

- A data exchange standard for all machine and system components. This eliminates the need to merge and convert data

- Universal, horizontal integration – from diagnostics on an HMI to networking of different systems across the world

- Reduction of fieldbus load

- Integrated certificate-based security solution