Hakkımızda

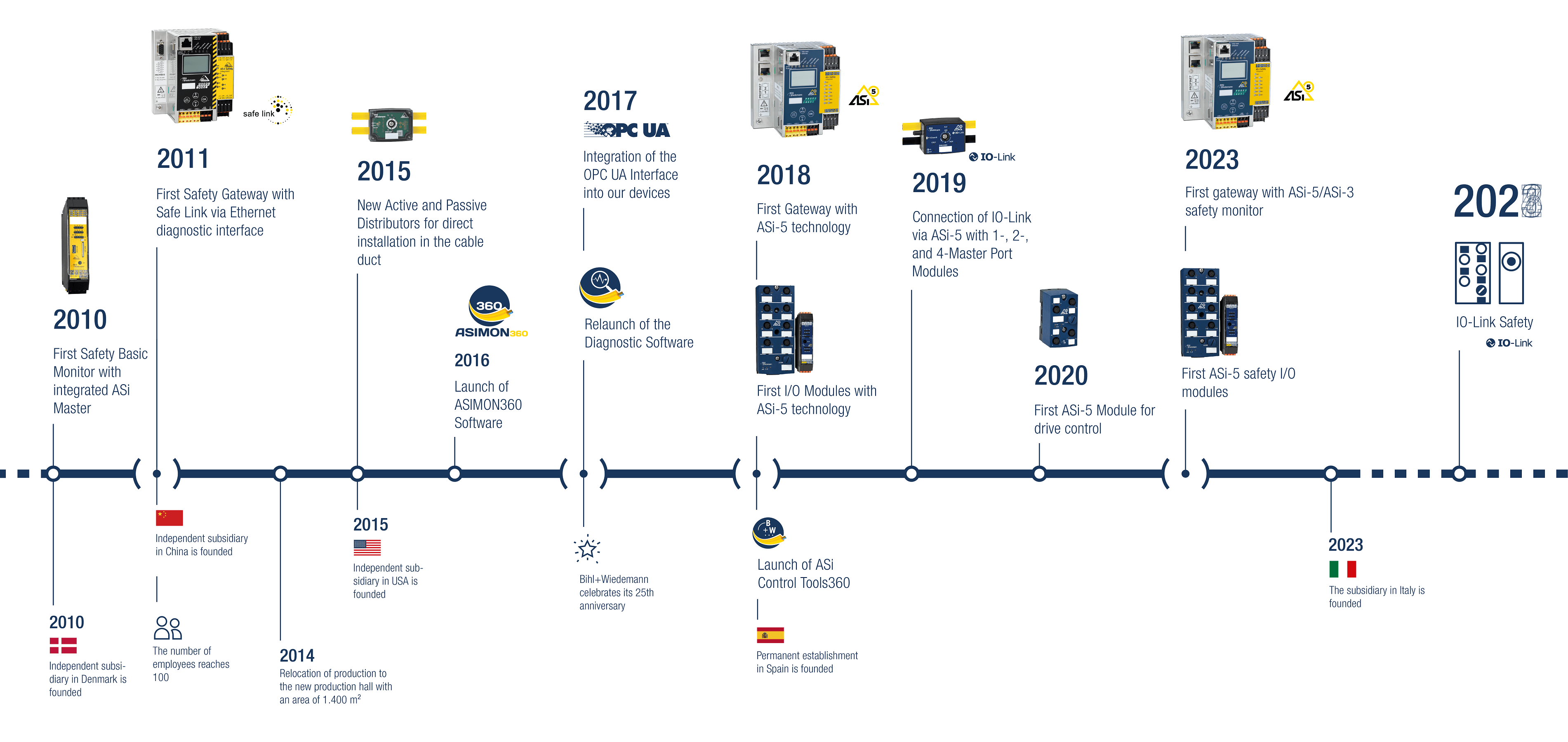

Bihl Wiedemann orta ölçekli, sahipleri tarafından yönetilen bir şirkettir – 1992 senesinde Mannheim’da Jochen Bihl ile Bernhard Wiedemann tarafından kurulmuştur. Fonksiyonel güvenlik ile makine ile ekipmanlardaki veri dolaşımı için eksiksiz otomasyon çözümleri geliştirip üretmekteyiz. Ürünlerimiz dünya çapında, örn. Önde gelen tüketici ve sermaye malları üreticiler tarafından kullanılmaktadır.

Müşterilerimiz için özellikle inovasyon ortağı olma amacını sürdürmekteyiz:

Bireysel istekler için öncü olarak geliştirme yetkinliğimiz.

1995’ten beri AS-Interface ile Lideriz

Bihl+Wiedemann AS-Interface (ASi) ile otomasyon ile güvenlik teknolojisinde teknoloji lideridir. Tüm ASi jenerasyonların gelişiminde dahil olduk. 1995 senesinde 300 ulusal ve uluslararası ortaklardan oluşan ASi kuruluşu olan AS-International e.V. tarafından ilk sertifikayı ASi masterimiz almıştır. ASi-5 ürünlerin pazar girişiminde de 2019 senesinde öncülük konumundaydık. Yeni ASi jenerasyonu ile daha büyük data miktarları artık hızlıca aktarılabilinmektedir. ASi Safety at Work ile fonksiyonel güvenlik alanında neredeyse 15 senedir önde gelen sağlayıcılar arasındayız.

Tüm ASi ürün portföyümüz şunlardan oluşmaktadır: Master/Ağ Geçitleri, Modüller/Slave’ler, Güvenlik Bileşenleri, Bus Dönüştürücü/Master Simülatörü ve kendi geliştirdiğimiz Yazılım.

Uluslararası Şirket Şubeleri ve Satış Ortakları

Yenilikçi gücümüz ve uzun yıllara dayalı müşteri ilişkilerimiz sayesinde yıllarca devamlı olarak büyümekteyiz.

Mannheim'daki merkezinin yanı sıra Bihl+Wiedemann'ın Türkiye, Danimarka, Amerika Birleşik Devletleri ve Çin'de şubeleri ve İspanya ile İtalya'da üretim tesisleri bulunmaktadır. Bunun dışında uluslararası satış ortaklarımız ile dünyada 30'dan fazla ülkede temsil edilmekteyiz.

CO2 - emisyonlarını azaltmak günümüzde hiç olmadığı kadar önem taşımakta. 2010 yılından itibaren enerji ihtiyacımızın birçoğunu kendi güneş panellerimiz ile karşılamaktayız. İlk elektrikli araçlarımız 2019 yılından itibaren kullanımdadır. Enerji verimliliğimizi ve çevre korumayı devamlı olarak iyileştirmek adına ISO 50001enerji yönetim sistemi ile ISO 14001çevre yönetim sistemini kullanmaktayız. Üç tesis'de bulunan ve toplam 270 kWp güce sahip güneş panelleri ile yılda 134.000 kWh ernerji miktarı elde edilmekte (2021).

Teknolojik Temel Bilgiler

AS-Interface

AS-Interface (ASi) dünya genelinde otomasyonun ilk seviyesinde standartlaştrılımış bir fieldbus sistemidir. Asi sensörleri ve aktüatörleri çift telli bir profil kablosu üzerinden tek bir yönetim ile birleştirilmektedir. Sarı kablo ile enerji ve veriler aynı anda aktarılmaktadır. Bunun dışında Asi'nin en büyük avantajı; kablolama işlemin büyük ölçüde azalması; topolojinin serbestçe seçimi ve aynı altyapı üzerinde Safety'nin entegrasyonu'dur. Asi-5'in yeni jenerasyonu ile artık daha büyük miktarda veriler önemli ölçüde daha hızlı aktarılmakta ve IO-Link gibi akıllı sensörler kolaylıkla entegre edilmektedir..

ASi Safety at Work

Otomasyon çözümlerinde emniyet ile ilgili konular daha da önem taşımakta – özellikle tehlikeli hareketler sonucu etkilenen insanların güvenliği konusu. Bu konuyla ilgili talimatlar AB'nin makine yönetmeliğinde (yönetmelik 2006/42/EG) veya ilgili ülkelerin İş Sağlığı ve Güvenliği Yönetmeliklerinde bulunmaktadır. AS-Interface'in Safety at Work konsepti ile emniyet ile ilgili bileşenler – emniyetli sensörler ve aktüatörler ile emniyet monitörleri – hatasız birşekilde neredeyse tüm kullanımda olan otomasyon sistemlerine entegre edilebilmekte.

DIN EN ISO 9001'e göre sertifikalı

2005 yılından itibaren Antalya genel merkezimizde ve 2011 yılından itibaren Antalya üretim tesisimizde DIN EN ISO 9001’e uygun bir kalite yönetim sistemine sahibiz. Bu sayede transparan süreçler oluşmakta ve tüm şirket alanlarında devamlı olarak iyileştirmelerin temeli atılmaktadır.

DIN EN ISO 14001 'e göre sertifikalı

2021 yılından itibaren genel merkezimizde DIN EN ISO 14001'e uygun bir çevre yönetim sistemine sahibiz. Bununla birlikte net çevresel hedefler tanımlanmakta; sürdürülebilir kaynak kullanımına yol açmakta ve çevreye zararlı güvenlik açıkları yok etmek için bir kilit nokta rolüne sahiptir.