ZPA and AS-Interface: a smart solution for controlled material flow

ZPA – pre-programmed, freely parameterizable

Achieve strictly defined distances between the conveyed unit loads with ZPA (Zero Pressure Accumulation). Thanks to a controlled material flow you can thus prevent unintentional collisions. ZPA is also energy-efficient because energy is only consumed when conveyed goods are actually being transported in the system.

Our pre-programmed ZPA solution allows you to implement zero pressure accumulation easily and cost-effectively. You benefit from autonomous and control-independent material handling. This is because there is no longer any need for centralized wiring and programming with the PLC. Other advantages include convenient, software-assisted configuration and detailed, fieldbus-independent diagnostic options.

Moreover, ZPA is compatible with all Bihl+Wiedemann ASi drive solutions – and thus with drive systems from a wide range of manufacturers.

Autonomous

material handling

Our ZPA solution lets you implement zero pressure accumulation for a wide variety of conveyed goods, such as cartons, containers or pallets – without the complexity of centralized wiring and PLC programming. Thanks to convenient scalability, it is possible to create simple, straight conveyor lines as well as customer-specific applications or autonomous safety solutions.

Fieldbus-independent

diagnostics

Thanks to our ZPA solution, you benefit from detailed and fieldbus-independent diagnostic options. At the core of the solution there is always an ASi-5/ASi-3 Gateway. On the one hand, it serves as a universal configuration interface for all modules of a zero pressure accumulation line. At the same time, the ASi-5/ASi-3 Gateway is also a diagnostic interface – to the PLC using common fieldbuses and thanks to the integrated OPC UA interface also to the IT.

Simple configuration

and parameterization

Our software suite (ASIMON360 and ASi Control Tools360) comes with basic settings installed and offers a convenient way to configure basic functions such as speed, start and stop ramps, or the conveying direction – even without prior technical knowledge. Additional functions such as follow-up times, watchdog times for missing conveyed objects or block removal can be activated via a user-friendly graphic interface.

Manufacturer-independent

ZPA extends the drive solutions, we offer for motorized rollers (Interroll, Itoh Denki, RULMECA), DC motors (EBM-Papst) and frequency inverters (SEW, NORD, Rockwell, Lenze, Bonfiglioli). You can therefore use our zero pressure accumulation conveyor technology with drive solutions from a wide range of manufacturers – even in mixed systems.

Save valuable resources

ZPA is very energy-efficient. This is because energy is only consumed when goods are actually being transported in the system. What's more, with AS-Interface you need almost no expensive plugs or sockets and only a single cable. This significantly reduces installation times and material costs. In addition, valuable resources such as expensive assembly and planning time, but also copper or plastic, which are required to manufacture the components, can be saved on a large scale. There is also a positive environmental effect when it comes to disposal – less waste is produced.

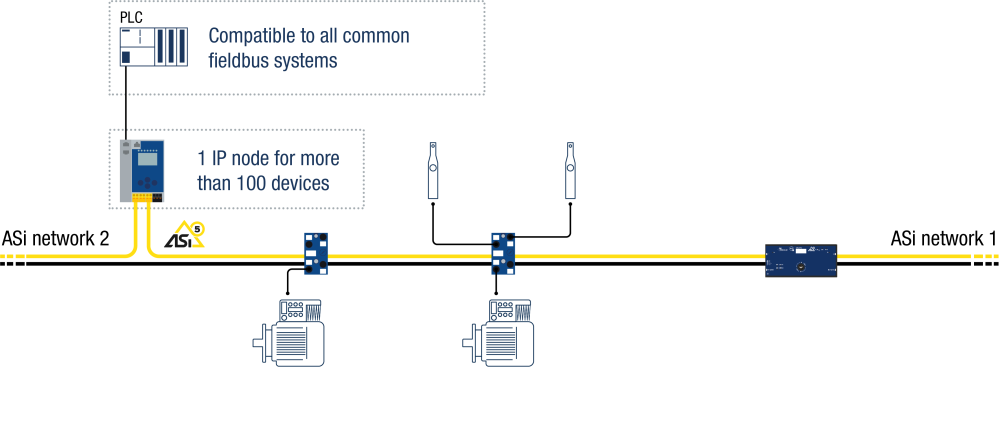

ZPA (Zero Pressure Accumulation) with Bihl+Wiedemann – connection to almost all PLCs

Bihl+Wiedemann's ZPA solution works independently of the control and drive solutions used in the system.

Via PROFINET, EtherNet/IP, Modbus, EtherCAT or POWERLINK, the ZPA solution can be connected to almost all common PLCs. All diagnostic information via ZPA is available for the PLC. Likewise, commands such as start/stop, change of directionof rotation or a global adjustment of the speed can be transmitted to the conveyor line. Switching, infeed/outfeed, barcode scanner as well as all specialties are solved with the help of the controllers on the same ASi circuit.

Individual commissioning with PC Software

You can easily implement our ZPA solution (BWU4921) with the Bihl+Wiedemann Software Suite (ASIMON360 and ASi Control Tools360) in three steps:

What is Zero Pressure Accumulation (ZPA)

Accumulation management is implemented within defined zones of the conveyor line that communicate with each other. In this process, a conveyed good is held back within a zone until the following section of the line is identified as being "free" by the logic. If the conveyed good accumulates, a signal is sent to the upstream zone, causing the material to be held back.

Zero Pressure Accumulation...

coordinates the flow of conveyed objects between infeed and discharge points including accumulation sections and buffer zones

guarantees that there are no "expensive" collisions or pressure on individual conveyed goods

is energy-efficient, as drives can be temporarily switched off in conveyor lines and accumulation sections of the conveyor where there are no conveyed goods.

ensures the highest possible and uniform utilization of conveyor lines and stations

enables targeted accumulation of objects in the event of a temporary system fault

ensures easier handling by creating gaps between objects