- AS-Interface

- Application

MOBILE, MULTIFUNCTIONAL, MODERN – THIS IS HOW ASi MODULES OF ALL GENERATIONS ARE ADDRESSED TODAY

The modern ASi-5/ASi-3 Address Programming Device BW4925 from Bihl+Wiedemann, a compact and ergonomic tool, can be used without any limitations with all ASi-5 and ASi-3 modules on the market. The same device can be used to write both ASi-3 addresses as well as node numbers and logical addresses of ASi-5 modules – the required ASi addressing cables are included in the scope of delivery.

In combination with the company’s software suite – ASIMON360 for safety applications and ASi Control Tools360 – the Address Programming Device shows off its virtues. Using the commissioning wizard integrated into the software you can quickly and very easily parameterize and commission modules which the device has addressed – in both small and large systems, from simple 16 I/O modules to parameterizable motor modules for frequency inverters and ASi-5 modules with integrated IO-Link masters.

Hardware and convenience on the cutting edge

The ASi-5/ASi-3 Address Programming Device shows off its hardware technology with cutting edge features. The OLED display can show razor-sharp plain text information and symbols regardless of the ambient light conditions and without glare. The six robust buttons allow you to operate the ergonomically designed device easily with just one hand – left or right. An integrated supercapacitor provides powerful energy storage.

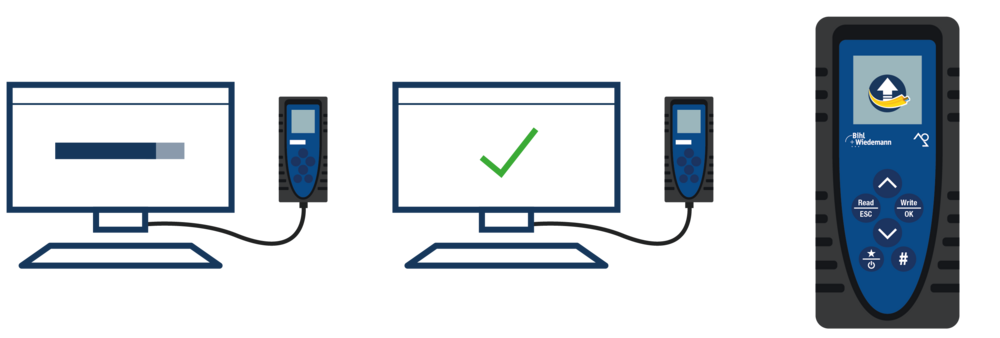

This offers not only long service life, but can also be used for more than 200 read/write operations when fully charged – with a charging time of just around 30 minutes. Self-discharge of the supercapacitor is minimal – the Address Programming Device is still ready to use even after several months on the shelf. If needed it can also be charged during use via a powerbank through the standard USB-C connection on the device. This is used not only as a charging port, but also as a PC interface through which you can load firmware updates taking all security aspects into account.

Menu structure and user experience: logical, intuitive, familiar

Users of the modern ASi-5/ASi-3 Address Programming Device now achieve the desired functions by means of a newly designed menu structure. This is based on the familiar look-and-feel of the software suites from Bihl+Wiedemann, especially when it comes to the integrated online bus information. The goal is to create a positive user experience by working with the tool in a logical, yet intuitive way.

Here the Address Programming Device offers clear icon symbols, among other things for the operating status. A crescent moon, for example, is used to clearly denote standby mode. Operating and input functions are indicated clearly and are self-explanatory – no more paging through the manual is needed. Instead of cryptically formulated information the ASi-5/ASi-3 Address Programming Device uses plain text for error messaging – and in various languages.

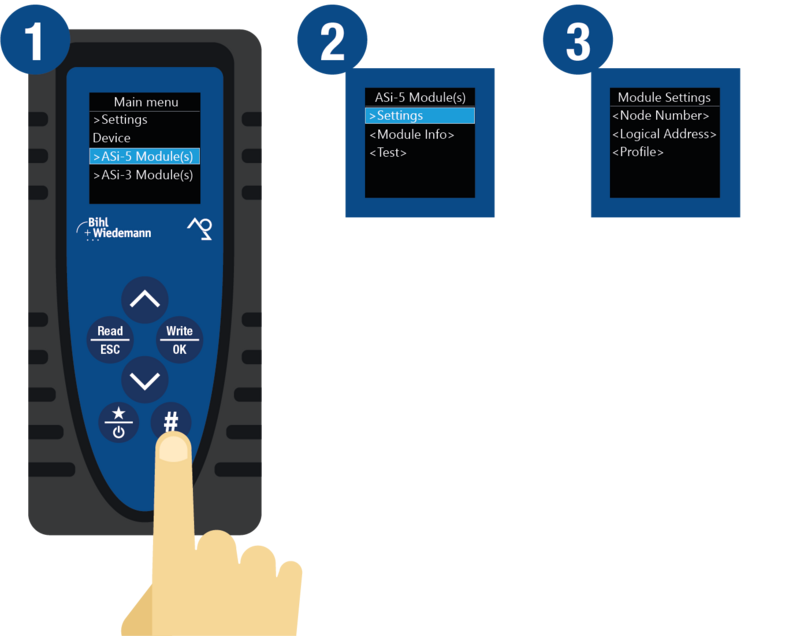

Two operating modes are available. In the addressing mode, users have access to the addressing functions for both ASi-5 and ASi-3 modules. The motto here: reduction to the essentials. You simply set the address or node number for the connected module. All the rest, such as logical address, profile used, parameters or even the name of an ASi-5 module is automatically set and parameterized from the PC software using the commissioning wizard.

The #-key takes the user to an expanded mode which supplements the addressing mode. Here you can read and write I/O data, i.e. inputs can be read and outputs can be set. Entering, checking or changing ASi-3 parameters is just as simple as reading and writing ASi-5 profiles. In addition, the Address Programming Device makes it possible to select profiles in the connected module and change various basic settings such as for different models and manufacturers of motorized rollers.

It is also possible – for instance – to reset ASi-5 participants to their original factory setting. Also available are numerous setting options for the ASi-5/ASi-3 Address Programming Device itself. For example, the times for the transition to stand-by mode or for completely switching off the device can be set via the menu.

And in the expanded mode, such as for maintenance or service operations, you can read out both the software package ID number (SPID) as well as the article number of an ASi module. This makes it possible to display the software version of updatecapable ASi devices on-site without having to be connected to the PC software.

Another special operating highlight is the ability to use the Address Programming Device to access the display of an ASi gateway directly through the device, even though the gateway is normally installed remotely in an enclosed control cabinet. The information displayed there is mirrored 1:1 on the addressing tool display and thus can be viewed remotely. This can significantly simplify and accelerate commissioning as well as service and maintenance work.

Commissioning with the modern ASi-5/ASi-3 Address Programming Device – it’s that easy

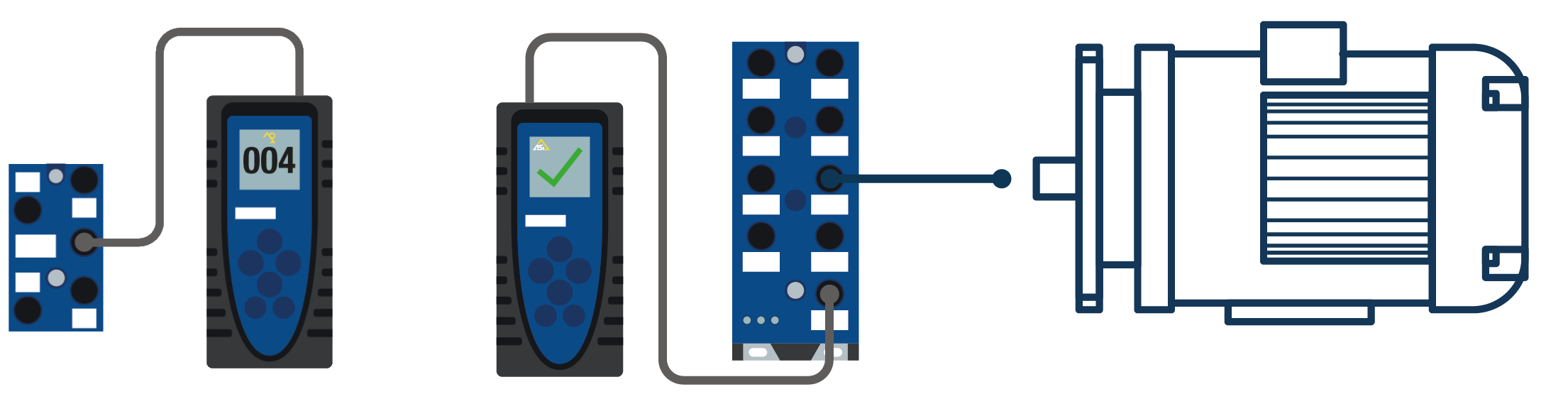

In general, all ASi modules can also be commissioned using just the software suites from Bihl+Wiedemann or directly through the gateway – but the ASi-5/ASi-3 Address Programming Device makes the work of commissioning an ASi circuit even easier. Once the network has been planned with respect to its hardware configuration in ASIMON360 or ASi Control Tools360, the bus participants can be quickly and easily provided with the address of an ASi-3 device or the node number and logical address of an ASi-5 module.

A real bus structure does not have to be available for this purpose. After these settings have been made locally for each individual module, all the devices are connected to the ASi gateway. Finally the software starts the commissioning wizard, which then automatically does the final configuration of all the connected devices

Additional settings are also transmitted to the ASi modules if they were already specified at the beginning of the hardware configuration. Hardware and network planning as well as parameterization of ASi modules using the Bihl+Wiedeman software suites, wiring of ASi modules and gateways in the control cabinet using piercing technology exactly where they are used, addressing of the control cabinet and field modules with the ASi-5/ASi-3 Address Programming Device, starting the automatic commissioning wizard – and you’re done!

AS-Interface, the globally standardized fieldbus system for the first automation level, can be commissioned and implemented quickly, intuitively, simply and reliably – in both small and complex applications