ASi-5 - Automation reinvented.

Your path into the digital future

ASi-5 is the latest innovation stage of AS-Interface (ASi), a globally standardised fieldbus system for the first automation level. ASi connects sensors and actuators with a controller via a single two-conductor profile cable. The yellow ASi cable transmits power and data at the same time.

The proven main benefits of ASi are, among others, dramatically less wiring, free choice of topology and cost-efficient integration of safety on the same infrastructure. In addition, compared to other fieldbus systems, ASi needs no connectors for data and power integration.

Content

- Your path into the digital future

- ASi-5 - great data bandwidth, short cycle times

- ASi-5 application reports from the field

- Bihl+Wiedemann’s ASi-5 products

- Compatible with all ASi generations

- ASi-5 – Your advantages at a glance

- New gateways and first input modules with safe and standard signals are available

- FAQ about ASi-5 Safety

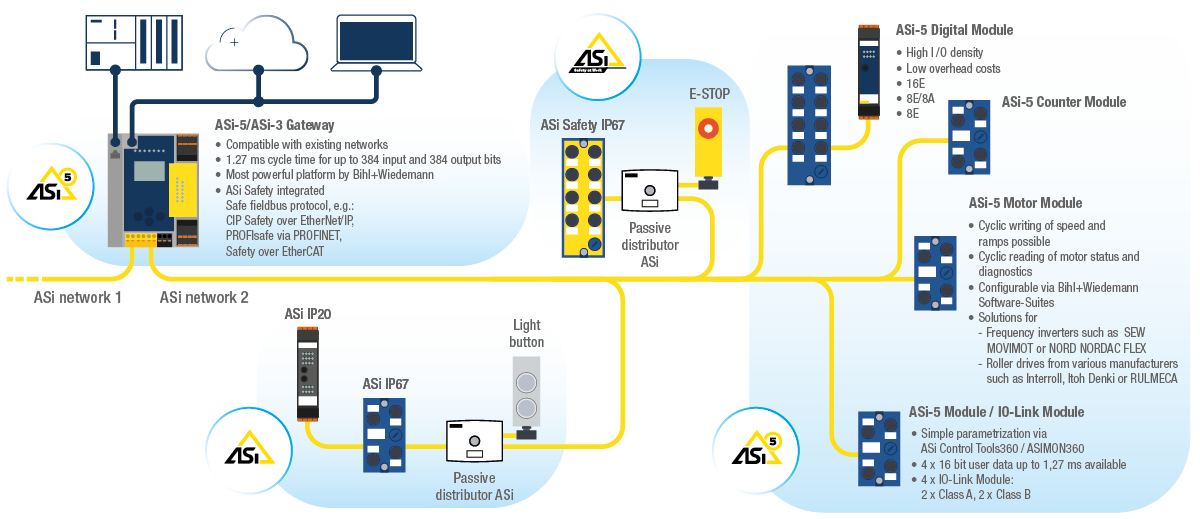

- ASi network with ASi-5 and ASi-3 products

- FAQs about ASi-5

ASi-5 - great data bandwidth, short cycle times

ASi-5 now enables you to transmit larger data volumes significantly faster. Great data bandwidth and short cycle times – comparable to Ethernet systems – allow for many new possibilities with AS-Interface. For example, ASi-5 now transmits analogue values much faster and it is easier than ever to integrate smart sensors, e.g., IO-Link sensors with up to 32 bytes.

Provides valuable information

More than anything, Industry 4.0 and increasing digitalization require a good data layer. As they supply additional data, smart sensors are becoming more and more important. This makes ASi-5 a key building block for your journey to the digital future, because there was one prevailing reason for evolving AS-Interface: being able to transport more and more data, without restrictions, to where they can yield valuable information. Using the integrated OPC UA servers of our ASi-5/ASi-3 gateways, you can even do this directly and in parallel with the fieldbus.

An affordable alternative

Another benefit of the significantly higher performance: Our new ASi-5 modules enable the cost-efficient and fast collection of numerous inputs and outputs in one place, making the modules an affordable alternative to other fieldbus solutions.

Compatible with all ASi generations

ASi-5 is compatible with all earlier ASi devices and components. Therefore, you can easily use ASi-5 modules together with ASi modules of any previous generation – in existing as well as in new ASi networks because all ASi generations work in parallel on the same cable.

If you already use ASi there is no need to replace existing ASi modules. Simply connect additional ASi-5 modules, for example in system sections with additional demands on speed, data volume or I/O density.

To use ASi-5 nodes all you need is a Bihl+Wiedemann ASi-5 / ASi-3 gateway. For the ASi-5 launch, this gateway is available in two variants: for PROFINETand EtherNet/IP. Both gateways have a double master and an integrated safety monitor. The OPC UA server, which is also integrated with both variants, makes it possible to easily transmit data directly from the field level to Industry 4.0 applications.

Without ASi-5 module, the new ASi-5 / ASi-3 gateways work exactly as earlier Bihl+Wiedemann gateways because the ASi-3 part remains unchanged. Using our new gateways you can easily replace existing gateways.

By the way, compatibility has been an AS-Interface trade mark for over 20 years. This protects not just your investments but each new ASi generation also makes you more future-proof.

ASi-5/ASi-3 Gateways are advantageous even without ASi-5 nodes

ASi-5/ASi-3 gateways are clearly the most powerful ASi-3 gateways. It is therefore also useful if you do not (yet) use ASi-5 modules in your system. Benefit from the advantages of our new ASi-5/ASi-3 gateways:

- Field update capability: Firmware and security updates are installed in a tamper-proof way; new functions are quickly available. Users decide for themselves which updates they want to install on the gateways and nodes of their choice.

- Integrated OPC UA server: Data from the field level can be transmitted directly and easily to Industry 4.0 applications.

- Integrated web server: among other things, it enables fast system diagnostics via remote maintenance or convenient addressing of the nodes during commissioning.

- Cyber security: The Ethernet fieldbus and Ethernet diagnostic interface are subjected to strict load tests by means of the Achilles test software Level 1 and 2 (Version 3.18); end-to-end encryption takes place via the Bihl+Wiedemann server.

ASi-5 application reports from the field

ASi-5 reduces machine costs, paves the way for IIoT, is ideal for demanding drive technology applications and introduces you to many new options thanks to its high data bandwidth and short cycle times. Here you can read a few of the many success stories involving the resource-saving bus system with the simplest connection technology.

Benefit from all well-proven ASi strengths...

- Transmit data and power in a single two-conductor profile cable

- Freely choose your topology without costly switches (ring, star, line)

- Cost-efficiently integrate safety on the same infrastructure

- Easily install and expand your system using ASi piercing technology

- Certified products for manufacturer-independent compatibility

- Affordable noise-resistant system that does not require shielding

… and from the new powerful ASi-5

- 1.27ms cycle time for up to 384 input and 384 output bits

- 16-bit I/O data and profiles with up to 32 bytes of process data for each node

- Easy integration of smart sensors and actuators such as IO-Link

- ASi-5 is compatible with all earlier ASi generations for combined use of different ASi modules

- ASi safety and ASi-5 easily work together

- Highly economical because of reduced costs per input / output

- Advanced diagnostics for predictive maintenance

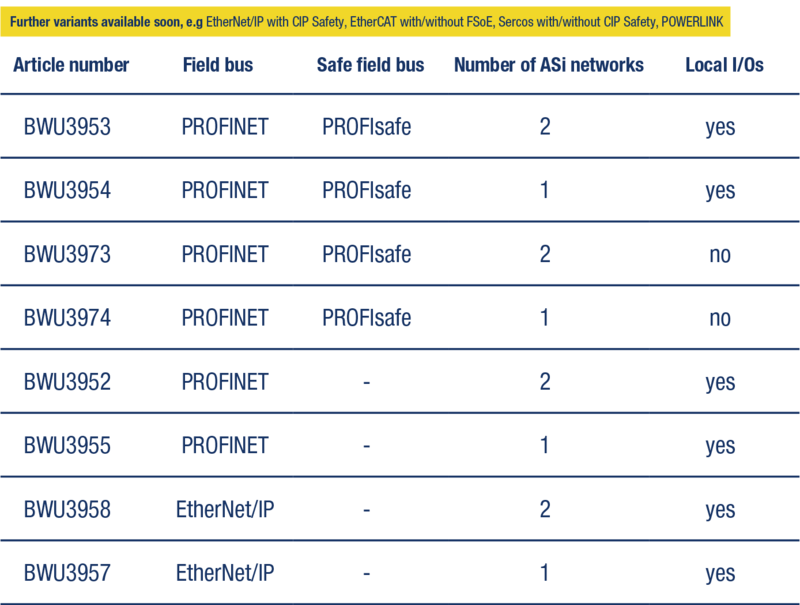

ASi-5/ASi-3 Gateways with Safety Monitor

Compatible with existing networks

- 1.27 ms cycle time for up to 384 input and 384 output bits

- Most powerful platform by Bihl+Wiedemann

- ASi Safety integrated

- Safety, PROFINET

- Safety, EtherNet/IP + Modbus TCP

- Safety, EtherCAT

- Safe fieldbus protocol

- CIP Safety via EtherNet/IP

- PROFIsafe via PROFINET

- Safety over EtherCAT

- CIP Safety via Sercos

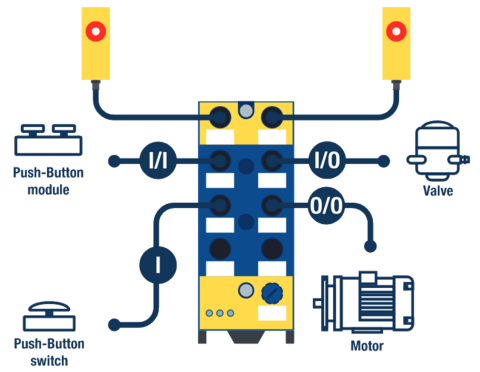

ASi-5 nodes

Here you can find the currently available ASi-5 nodes. We will continuously develop additional product variants.

ASi-5 Safety input modules

- Convenient parameterization via ASIMON360

- For floating contacts or for OSSDs or a combination

- 2 × 2-channel safe inputs

- Up to 12 standard I/Os

- Special solutions for Muting applications

- Only 1 ASi-5 address

ASi-5 motor modules

Input power provided by ASi

Motors supplied from AUX

Cyclic writing of speed and ramps possible

Flat design, installation in cable duct possible

Control of up to 4 × 48 V motorized rollers per module (e.g. Interroll)

Control of up to 4 × 24 V motorized rollers per module (e.g. Interroll, Itho Denki)

Drive solutions with Serial Interface (e.g. SEW, Lenze, NORD, EBM-Papst, Rockwell, Bonfiglioli)

Jochen Bihl introduces the ASi-5 Module with integrated IO-Link Master with 4 ports from Bihl+Wiedemann. The ASi-5 module can transmit up to 32 bytes of I/O cyclic data – which fits IO-Link perfectly. By default the modules transmit over AS-i a total of 8 bytes – 2 bytes per port – in 1.27 ms.

Video length: 2:39

New gateways and first input modules with safe and standard signals are available

ASi-5 Safety is certified and ready for use and complements optimally the established ASi Safety. The latest Safety generation can be easily integrated into existing solutions. Main advantage of ASi-5 Safety: You can use many safe and standard signals under just a single address.

Discover now our new ASi-5/ASi-3 Gateway family with integrated ASi-5 Safety - as well as the first ASi-5 Safety input modules with 2 safe inputs each and up to 12 standard signals. With them, you can, for example, implement cost-effectively the connection of an operating panel to ASi - with several light buttons, an emergency stop button and a safe key switch.

The first ASi-5 Safety input modules

Bihl+Wiedemann has steadily expanded its safety technology solution portfolio since 2005. After a short overview of previous Safety highlights, product manager Paul Werge presents the first two ASi-5 Safety input modules in IP67: BWU4209 has 2 safe inputs for floating contacts, BWU4210 has 2 safe inputs for optoelectronic devices. Both modules additionally have 12 digital self-configuring I/Os each.

Video length: 1:54

There are already many different safety controllers and solutions on the market, but unfortunately the same is also true for the number of functionally safe protocols used and the fieldbus itself.

Fieldbus independence has always been a great strength of ASi and ASi Safety. There are gateways for almost all relevant fieldbuses and safety protocols. This makes the system architecture at the I/O level completely independent of the used controller, which means that it can be standardized across all applications.

Needless to say, this advantage also applies to ASi-5 Safety. Just as with the introduction of ASi-5 in the standard area, ASi-5 Safety also offers many new options. The higher data bandwidth and extended diagnostic and parameterization options are ideal for resource-intensive applications.

This for example, makes the future implementation of IO-Link Safety possible.

ASi-5 Safety has been an integral part of ASi-5 from the very beginning: both use the same communication technology. In the case of ASi-5 Safety modules, only the normatively required protection of the data is added - with an additional checksum.This makes the transmission of these signals functionally safe up to SIL 3/PLe. This is essential whenever standards require such functional safety to protect people and the environment.

Just like ASi-3 Safety at Work, ASi-5 Safety was once again tested and certified externally according to applicable functional safety standards. Similarly, the process used for ASi-5 Safety achieves a performance level up to PLe according to ISO 13849-1, or a safety integrity level up to SIL3 according to IEC 61508/62061.

Of course, even standard sensors can be connected to ASi-5 Safety modules. With many modules, it is even possible to reconfigure connections so that the signal of the standard sensor is only transmitted via the standard protocol. This especially conserves communication resources such as addresses and bandwidth for ASi-3 Safety modules.

An additional advantage of ASi-5 Safety is that many safe and standard signals can be connected and transmitted over a single address. This saves resources and above all costs.

The topic of cyber security is more relevant than ever. In the industrial sector, the reliability of processes and production in particular is becoming increasingly important.

Like the standard ASi-5 communication, ASi-5 Safety is almost tap-proof due to the nature of the system. The reason: the data transfer via OFDM with dynamic frequency assignment,makes it very complex to capture the exchanged messages. This requires the entire context of the connection set-up between ASi master and ASi node. Besides, the clock frequencies must be precisely synchronized just like between the ASi master and ASi node according to the ASi-5 protocol.

Cyber security is also enhanced by the fact that the gateway creates a logical break between TCP/IP, ASi-5, and ASi-5 Safety. This means that high safety requirements only need to be placed on the ASi-5 Master, which establishes the connection to TCP/IP. ASi-5 modules, on the other hand, are much less problematic in terms of safety, since they cannot communicate over TCP/IP networks. Those responsible for network security can thus focus on significantly fewer devices and check them more carefully.

As an integral part of ASi-5, ASi-5 Safety can transmit safe and standard data simultaneously. Up to 32 bytes are available cyclically for this purpose. The safe data always has a 1-byte checksum, which enables safe communication up to level SIL3/PLe. As with pure ASi-5 standard modules, there is also a diagnostic and an acyclic channel. This also allows ASi-5 Safety modules to transmit detailed diagnostic messages in case of an event. An additional high-performance method is also available to read out additional information if required – e.g., for predictive maintenance or similar applications.

ASi-5 Safety uses the same mechanisms as all other ASi-5 modules. This means that it provides cyclic data along with an event-based diagnostic channel and an acyclic channel for reading out numerous indices. These indices cover a wide range of information: manufacturer, model name, the ASi ID for unique identification, module temperature, measured currents or an hour meter, to name a few." OPC UA enables this information to be transmitted to IT for evaluation..

This can save considerable costs in applications with multiple signals. ASi-3 Safety can also be used for modules that have many signals. In this case, however, each safe signal occupies a separate address. Just as with ASi-5, ASi-5 Safety can process much more data per master and thus greatly reduce connection costs – thanks to the significantly higher data bandwidth per address. For example, with the ASi-5 Safety module BWU4210, a total of 2x2-channel safe inputs and an additional 12 I/Os are available under just one ASi-5 address. In contrast, the same amount of data occupies 2 single and 3 A/B addresses with ASi-3.

However, ASi-5 may not always be the most advantageous one. Even with ASi-3 Safety, only one address is occupied for a single E-stop with a 2-channel safe input – and at lower cost. Both technologies will therefore be used in parallel in the future.

ASi-5 and ASi-3 operate independently and in parallel on the same two-conductor cable with the same electromechanics. Only one gateway with a combined ASi-5/ASi-3 master is required when using both protocols in one installation. The same applies to ASi-5 Safety and ASi-3 Safety – all that is needed is a gateway with a combined master and a combined ASi-5/ASi-3 safety monitor. In the simplest case, it is therefore possible to just replace the gateway in an existing system with ASi-3 Safety. The system can then continue to operate without changes, and ASi-5 Safety modules can be easily added if necessary.

Do you have questions about ASi-5 Safety? Or do you need a special product?

We will be happy to inform you about the new Safety Generation. Please also contact us if you need a specific ASi-5 Safety Module or a gateway with ASi-5 Safety Monitor.

No. ASi-5 is the evolution of the well-proven AS-Interface standard. ASi-5 offers all the advantages that have already made ASi so special in the past. For example, power and data are still transmitted over a single cable, you have free choice of your topology and the safety technology is still on the same infrastructure. The main reason for evolving ASi was the fact that Industry 4.0 and increasing digitalization brings with it ever greater volumes of data. ASi-5 has both a large data size and short cycle times, making it possible to transport more and more data, without restrictions, to where they can yield valuable information.

Yes. ASi-5 is compatible with all earlier ASi devices and components, meaning that ASi-5 nodes can be combined with ASi nodes of any generation—in existing as well as in new ASi networks. In an existing ASi network, you can simply connect additional new ASi-5 slaves and easily continue to use existing ASi nodess. To use ASi-5 nodes all you need is a new Bihl+Wiedemann ASi-5 / ASi-3 gateway.

In particular for applications with high transmission speeds or high data volumes. In addition, in places where a concentrated and cost-efficient collection of a larger number of inputs and outputs is needed. In many cases, Bihl+Wiedemann’s new digital ASi-5 modules can be an affordable alternative to other fieldbus solutions.

No. In principle, they can be configured without software but we always recommend the more comfortable option using our software solutions. Our software Suite enables you to easily plan, configure and parameterize ASi networks with or without safety. If you already use the software for your ASi network, all you need is a free update to be able to continue using it for ASi-5 applications. The software is as intuitive and comfortable to use as with ASi-3. An integrated hardware catalogue encompasses the complete ASi product range. All you need to do is click the device you need when configuring the ASi circuit. The new online bus information also enables you to easily address slaves and monitor inputs and outputs. This function makes it even easier to integrate IO-Link sensors.

Like all ASi generations, ASi-5 is a joint development of several manufacturers of AS-Interface products. The complete project took more than 200,000 developer hours, evolving the idea of a new ASi generation into a mature trendsetting technology. Now that the main project has been completed, the involved companies continue to work on standards and certifications for new ASi-5 products.

By combining ASi-5 and ASi-3 slaves on one ASi circuit, it is possible to connect at least 62 nodes – in many cases, even considerably more.

The Bihl+Wiedemann hardware catalog tells you how many ASi nodes can be connected for specific applications. It is integrated in our ASIMON360 and ASi Control Tools360 software. So a warning appears if the maximum possible number of ASi-5 and ASi-3 slaves is exceeded. In addition, vacant ASi-5 transport channels can be shown at any time when planning.

Our experts will gladly answer any further questions you may have.

Yes, the use of ASi-5/ASi-3 gateways brings advantages in any case – even if you do not (yet) use ASi-5 nodes. This is because the new ASi-5/ASi-3 gateways are also the most performant ASi-3 gateways. Their advantages:

- Field update capability: Firmware and security updates are installed in a tamper-proof way; new functions are quickly available. Users decide for themselves which updates they want to install on the gateways and slaves of their choice.

- Integrated OPC UA server: Data from the field level can be transmitted directly and easily to Industry 4.0 applications.

- Integrated web server: among other things, it enables fast system diagnostics via remote maintenance or convenient addressing of the slaves during commissioning.

- Cyber security: The Ethernet fieldbus and Ethernet diagnostic interface are subjected to strict load tests by means of the Achilles test software Level 1 and 2 (Version 3.18); end-to-end encryption takes place via the Bihl+Wiedemann server.

The replacement device must have the same part number. You can then replace the defective node without using a hand-held addressing device or additional programming work. The additional steps necessary depend on the slave type used (e.g. standard or safety). You can find more information in our video tutorial.

If you encounter problems or issues related to this topic, please contact our support team. Our product specialists will be happy to assist you.

Tel.: +49 621 33996-0

E-Mail: mailbihl-wiedemann.de

The replacement device must have the same part number. You can then replace the defective master without additional programming work. Please attach to the following necessary steps:

- Disconnect the defective safety monitor from the power supply and from the ASi network.

- Remove the chip card from the top of the defective unit and insert it into the replacement unit.

- Connect the new monitor to the ASi network and the power supply.

- The display menu of the monitor willguide you through the copying process to help you transfer the stored configuration from the chip card to the device.

- You may be asked to specify the direction in which the copying process is to be started – in this case, select "Chipcard > Master".

- Enter the release code of the configuration and confirm this code. The safety monitor then starts and the transfer is completed.

The above steps are described in detail in our video tutorial.

If you encounter problems, please contact our support team. Our product specialists will be happy to assist you.

Tel.: +49 621 33996-0

E-Mail: mailbihl-wiedemann.de

Already during the development of ASi-5 we made sure that IO-Link will be perfectly embedded in ASi-5 and our user-friendly PC software - from the device to the PLC or cloud.

Our mature concept enables IO-Link data to be transmitted transparently via ASi-5. The fieldbus-independent solution combines the advantages of IO-Link and ASi-5, allowing up to 64 ASi-5 modules, each with 1, 2, 4 or 8 IO-Link ports, to be connected to an ASi-5 master. The maximum possible data frame of an IO-Link device (32 bytes) can be mapped without any problems.

Thanks to ASi, you also benefit from drastically reduced wiring effort without swichtes, great freedom in the choice of topology, and a smart power supply concept.

You can find more information here.

This could also be of interest to you

Self-configuring I/O modules

The modules can be used flexibly and are cost-effective, making them a good alternative to comparable Ethernet or IO-Link-based I/O solutions.

ASi-5/ASi-3 Address Programming Device

Learn more about the user-friendly ASi-5/ASi-3 address programming device for easy addressing of modules of all ASi generations.

Drive solutions with ASi-5

Our drive solutions based on ASi-5 are characterized by short cycle times and high data size. Discover our ASi-5 motor modules for leading manufacturers, such as Lenze, Interroll and SEW-Eurodrive.

AS-Interface

The standardized fieldbus system AS-Interface (ASi) helps you drastically reduce your wiring complexity. You also benefit from free choice of topology and cost-effective integration of safety features on the same infrastructure.

![[Translate to Englisch:] ASi-5 Datenbreite [Translate to Englisch:] ASi-5 Datenbreite](/fileadmin/_processed_/8/f/csm_ASi-5-Icon-Autobahn_8daec96033.png)

![[Translate to Englisch:] ASi-5 Zykluszeit [Translate to Englisch:] ASi-5 Zykluszeit](/fileadmin/_processed_/b/c/csm_ASi-5-Icon-Stopuhr_6f0a6202b3.png)

![[Translate to Englisch:] ASi-5 Kompatibilität [Translate to Englisch:] ASi-5 Kompatibilität](/fileadmin/_processed_/b/d/csm_ASi-5-Icon-Puzzle_4b27479278.png)

![[Translate to Englisch:] ASi-5 IO-Link Integration [Translate to Englisch:] ASi-5 IO-Link Integration](/fileadmin/_processed_/7/1/csm_ASi-5-Icon-Birne_cccb01b93a.png)

![[Translate to Englisch:] ASi-5/ASi-3 Gateways mit integriertem Sicherheitsmonitor [Translate to Englisch:] ASi-5/ASi-3 Gateways mit integriertem Sicherheitsmonitor](/fileadmin/_processed_/3/9/csm_BWU3674_a7180bdb73.png)

![[Translate to Englisch:] ASi-5/ASi-3 Gateways in Edelstahl [Translate to Englisch:] ASi-5/ASi-3 Gateways in Edelstahl](/fileadmin/_processed_/6/1/csm_3848_ebecc82698.png)