IO-Link with Bihl+Wiedemann: easy, flexible, fieldbus-independent

IO-Link devices are nowadays common in machines and systems. This is because IO-Link allows sensors and actuators to be connected to the control level via a powerful point-to-point connection. Find out more about the general advantages of IO-Link and the associated advantages here.

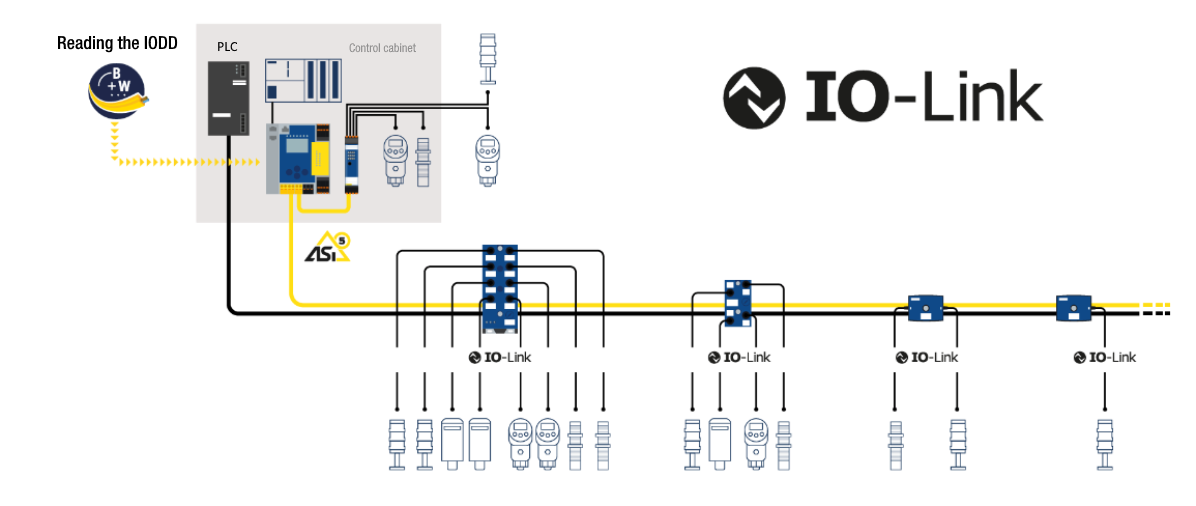

This page mainly deals with the following question: What is the best way to integrate IO-Link? Bihl+Wiedemann offers you a sophisticated concept for this: IO-Link can be embedded perfectly in ASi-5 and our user-friendly PC software – from the device to the PLC or cloud. Our solution is suitable for all fieldbus systems, e.g., PROFINET, EtherNet/IP, or EtherCAT. In addition to fieldbus independence, you benefit from freedom in the choice of topology, reduced wiring complexity without switches, and a smart power supply concept. Other advantages of our solution include reduced IP management complexity and low-cost IO-Link masters, which we provide with 1, 2, 4 and 8 ports. Numerous technical features also enable you to commission IO-Link devices with maximum convenience. For us, one thing is certain: There is no smarter and more economical way to integrate IO-Link.

The IO-Link master is integrated as an ASi node into the ASi network

IO-Link devices can be integrated into the ASi network along with standard sensors, standard actuators and safety components

All process data (up to 32 bytes per port) of the IO-Link devices is available via the cyclic ASi communication.

All IO-Link parameters can be conveniently adjusted through the B+W Software Suite or acyclically via the control system

Diagnostic information from IO-Link available via ASi

Our IO-Link masters can be optimally combined with IO-Link devices from any manufacturer

If an IO-Link device needs to be replaced, its parameters are stored in the IO-Link master and are transferred automatically to the new one.

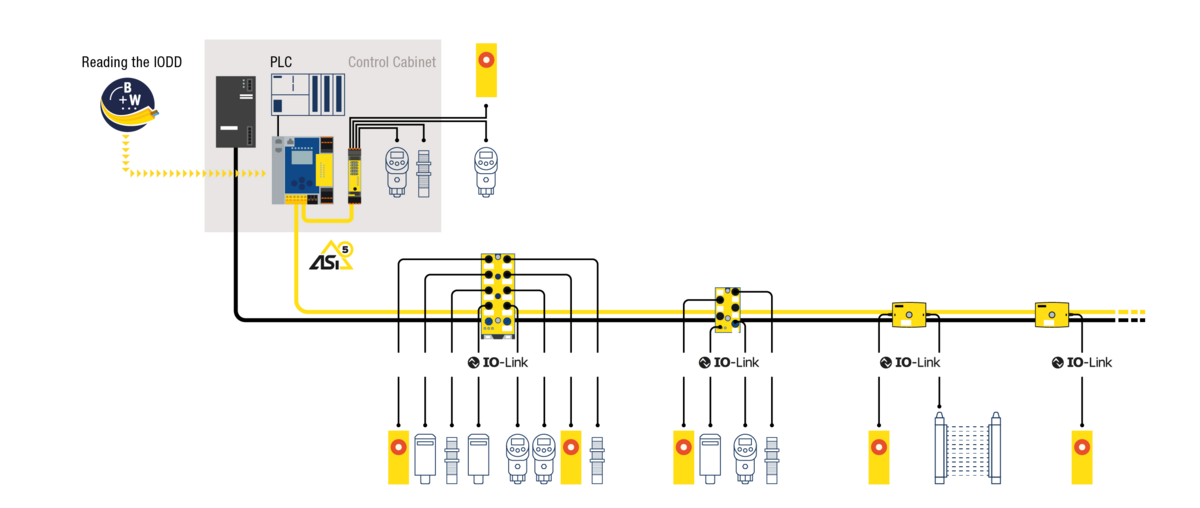

IO-Link Safety Solutions from Bihl+Wiedemann

IO-Link Safety is an extension of IO-Link. There is an additional safety communication layer on the master and device side. These become the "Fail-Safe (FS) master" and "Fail-Safe (FS) device". Bihl+Wiedemann is in the process of developing its own "FS master". IO-Link is already a perfect match for the safety components of Bihl+Wiedemann.

Reduced machine-related costs

A cost-efficient standard cable establishes a connection up to 20 meters long between the IO-Link master and IO-Link device.

High machine availability

Downtimes are reduced because when a defective IO-Link device is replaced, its parameters are automatically transferred to the new sensor by the IO-Link master or control system.

Efficient operation

IO-Link devices can be positioned in the machine directly at the work site. These do not have to be accessible for parameterization.

Demand-oriented maintenance

Continuous diagnostic data of the entire process lengthen maintenance intervals, since systems and machines need to be maintained much less frequently due to the automatic readjustment via IO-Link

It is possible to extend existing bus systems. As a prerequisite, the system mapping of IO-Link for the respective bus system must be already implemented. It is particularly easy to use IO-Link in conjunction with the ASi intelligent wiring system. Thanks to piercing technology, corresponding IO-Link masters can be easily retrofitted where they are needed.