- AS-Interface

- Technology

DRIVE AND MATERIAL HANDLING TECHNOLOGY WITH ASi-5: EXPANDED PORTFOLIO AND PERFORMANCE

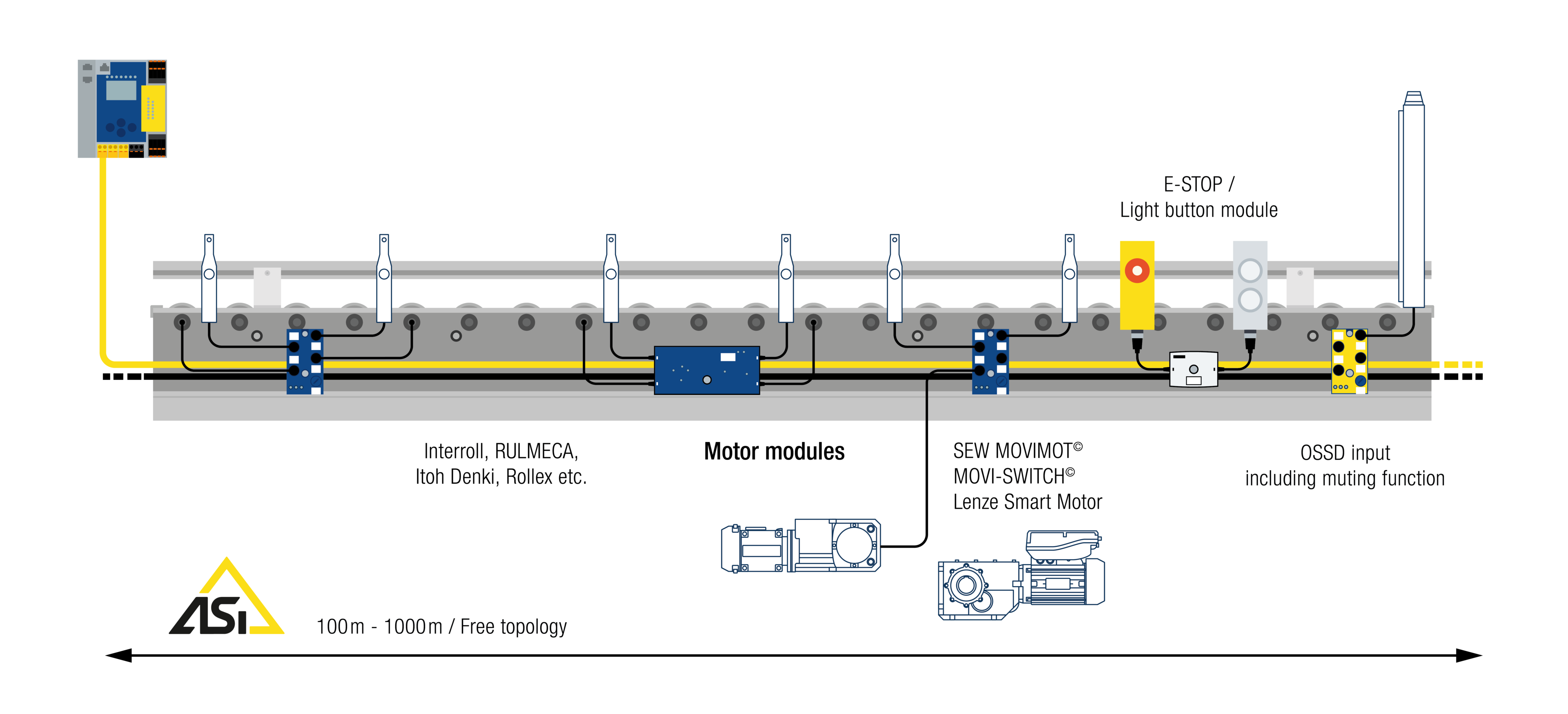

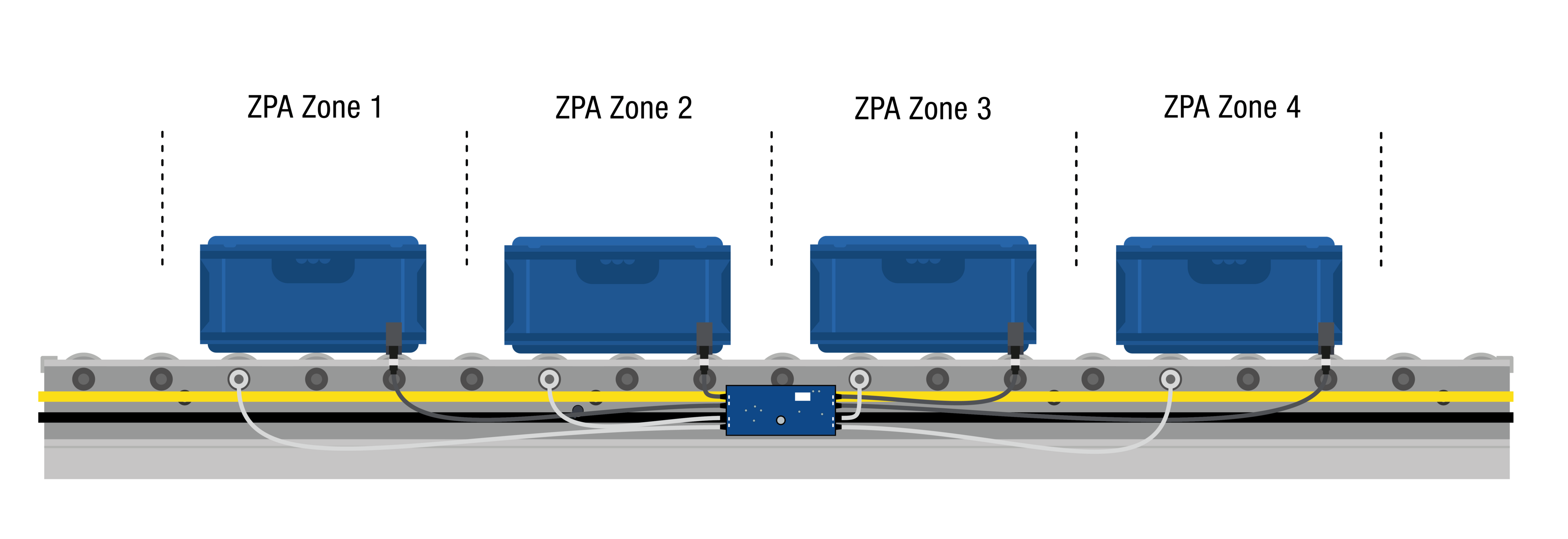

Back in spring of 2022 the company drew great attention when they presented their ZPA solution for zero pressure accumulation in buffer and accumulation lines of stationary material flow systems. Zero pressure accumulation with Bihl+Wiedemann enables autonomous and PLC independent integration of motorized rollers, DC motors and frequency inverters from various manufacturers and in different power classes while at the same time providing detailed and fieldbus-independent diagnostics. The modules for manufacturers of motorized rollers such as Interroll, Itoh Denki and RULMECA and for suppliers of DC motors and frequency inverters such as Lenze, SEW-EURODRIVE and NORD DRIVESYSTEMS that have been available in the portfolio to date have now been joined by modules for drives from Rockwell Automation, ebm-papst and the Italian drive and electric motor specialist Bonfiglioli. This makes the Bihl+Wiedemann systems solutions for ASi-3 and ASi-5 compatible with drive infrastructures that are standard in modern material flow plants everywhere. The portfolio is rounded out with other new developments such as the new 24 V brake chopper for limiting voltage feedback to the supply line, and the new ASi-5 cable duct modules.

New 24 V brake chopper manages feedback of generative energy

The new BWU4915 brake chopper in protection class IP67 limits the overvoltage when operating 24 V roller drives that results when braking the drive caused by feedback on the AUX line. It prevents undesired mains interruptions or error messages caused by overload. Each brake chopper is able to compensate the overvoltage of at least 2 rollers simultaneously, in many cases even more. The module is simply and quickly connected to the black AUX profile cable using piercing technology – with the flat housing of the module perfect for installation in the cable duct and other types of cable guides. Two integrated LEDs on the module enable quick and easy on-location diagnostics by indicating whether a voltage is correctly applied and whether energy that has just been actively fed back is compensated.

Integrate up to four motorized rollers flexibly and cost effectively

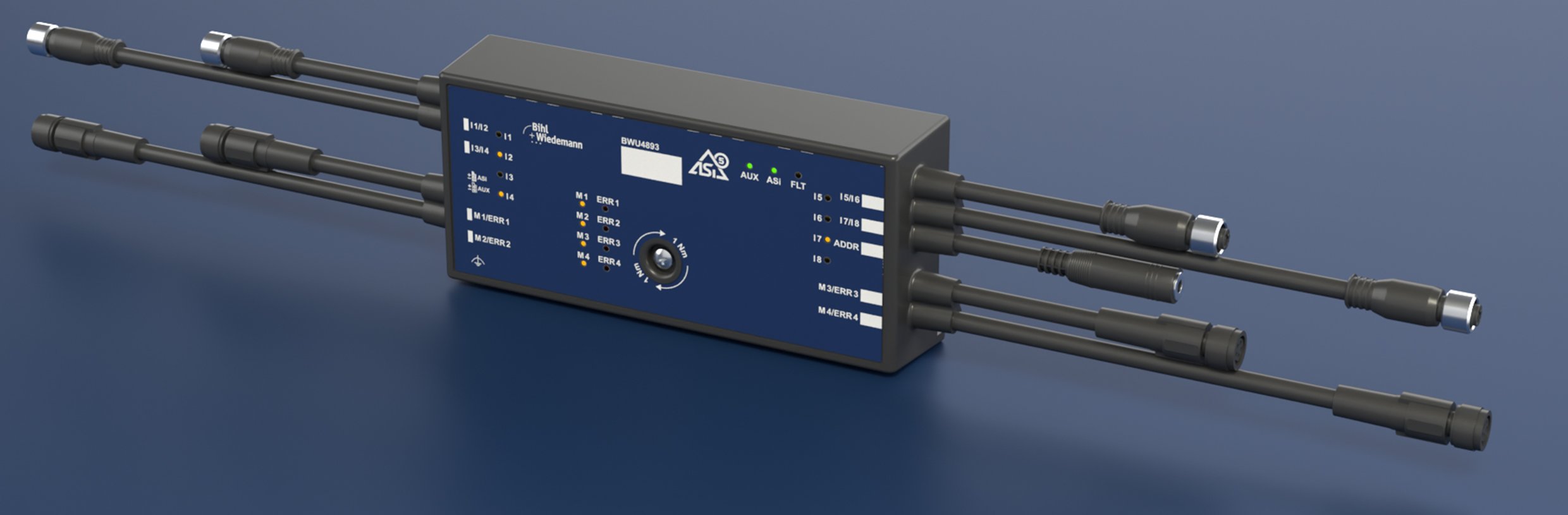

The new BWU4893 and BWU4894 ASi-5 cable duct motor modules for 24 V and 48 V make connecting quantities of roller drives in an application even more elegant and cost-effective. The type of construction and dimensions of the housings as well as the integrated cables for sensors and motors were optimized for simple, space-saving installation in the cable duct along the material flow line. Up to four motorized rollers and up to eight sensors can be connected and supplied on each module. Each of the four rollers can – as is typical for ASi-5 – be individually and thus extremely flexible controlled – and all under a single ASi-5 node number (ASi address). Various status LEDs provide assistance during commissioning, and during operation permit simple diagnostics of the inputs in case of a motor fault. Protection degree IP54 takes into account the conditions inside a cable duct – which with a specified temperature range of -30 °C to +70 °C enables the use of the new motor modules in both cold and deep-freeze environments and in conveying lines characterized by corresponding higher ambient temperatures.

Of particular interest for material flow applications with these modules is the ability to write the speed as well as the start and stop ramps steplessly with cycle times down to 1.27 ms – ideal for demanding applications. But in addition each of the new ASi-5 cable duct modules provides the option of up to four autonomous ZPA zones – conveniently using the PC software from Bihl+Wiedemann, without the need for a higher level controller and the associated programming effort and regardless of which drive solution is used in the plant. Together with the likewise available ASi-5 cable duct modules for two motors, the number of unused motor connections is minimized and wiring costs reduced.

AS-Interface, the perfect wiring technology for drive solutions

The classical advantages, such as

- reduced wiring effort thanks to the ASi cable,

- the ability to connect ASi modules exactly where they are needed using mistake-proof piercing technology,

- the free selection of line, tree, ring or star topology when designing the plant layout,

- transmission of standard and safety signals on the same cable

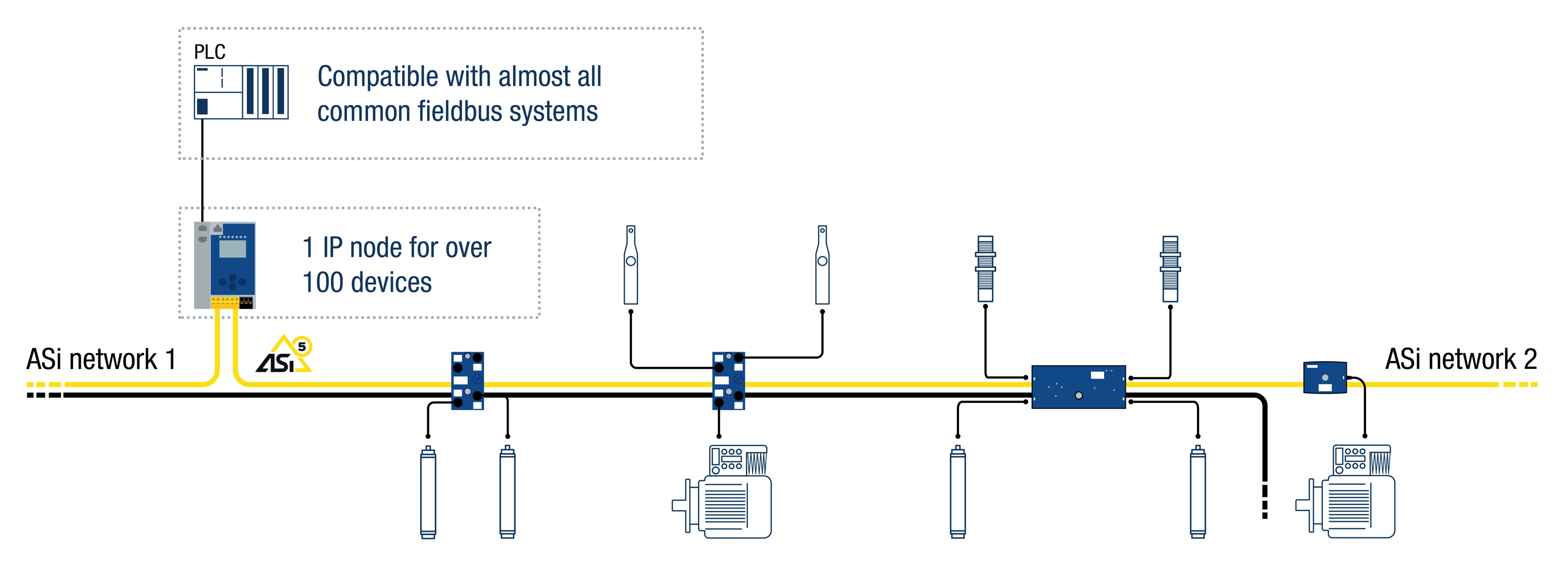

as well as the wide range of products and their easy integration using the Bihl+Wiedemann PC software with its hardware catalog for drag-and-drop system configuration, parameter cloning for faster commissioning of identical drives, ZPA parameterization and commissioning wizard have all been essential factors in AS-Interface establishing itself as an internationally standardized wiring system in drive technology as well. While the above arguments apply to all ASi generations, i.e. for ASi-3 as well, which is ideal for simple applications such as collecting binary signals, the new standard ASi-5 offers even more benefits, in particular

- greater data bandwidth,

- faster transmission rates,

- significantly more efficient addressing of the ASi devices (just one IP node for over 100 ASi modules)

- the ability to integrate intelligent IO-Link devices, as well as

- expanded channel-specific diagnostics, even more comprehensive and detailed error messages and solution prompts.

Thanks to the OPC UA server integrated in the gateway, the key information about the ASi network – process data and diagnostics – are also available for typical Industry 4.0 applications. In addition, cyclically important performance characteristics such as supply voltage and the actual motor current are transmitted. In practice motor modules are of course often used only in ASi-3 or ASi-5 applications, but in many cases mixed installations make a great deal of sense – such as when a simple indicator light is controlled by ASi-3 but the frequency inverter by ASi-5.

Standardized and safe: The user experience

Thanks to the wide range of motor modules and gateways, drive solutions using AS-Interface from Bihl+Wiedemann are independent of which controllers or drives are used in the system. Any already developed ASi installation can be ported in its entirety, for example to a different automation environment. In addition, thanks to standard-ized drive profiles, drive technology always seems to be the same with Bihl+Wiedemann – simple and convenient, regardless of which drive is used. The comfortable user experience also applies when parameterizing frequency inverters and DC drives made by different manufactures. This is ensured by a transparent parameter channel in the PC software from Bihl+Wiedemann. The freely available parameters and values are first stored in the motor module based on the manufacturer documentation, and then loaded into the drive at commissioning. This means the drives can be parameterized and placed in service using ASi directly and without any additional software or a direct connection to the drive. If a large number of drives need to be parameterized, this is easily accomplished using copy-and-paste in the PC software. This can significantly reduce the amount of time required. The highest availability during operation is ensured by the additional backup in the motor modules and in the ASi master, since storing of the parameters enables smooth spare parts replace-ment while at the same time preventing errors when replacing motors or motor modules.

Smart automation platform for material flow

AS-Interface is not only a simple and secure connection technology for automation components in the field – probably no other wiring technology makes it possible to integrate individual components such as devices into conveying systems in large numbers as cost effectively and efficiently. AS-Interface from Bihl+Wiedemann is even more – high-performance gateways and modules make ASi-3 and ASi-5 a smart automation platform on the lower field level – with variable connectivity to higher level fieldbus systems and control levels such as found in storage and material flow technology, in conveying and sorting systems or in picking systems.