- AS-Interface

- Technology

INDUSTRIAL INTERNET OF THINGS: FAST AND SAFE INTO THE IIOT WITH ASi-5

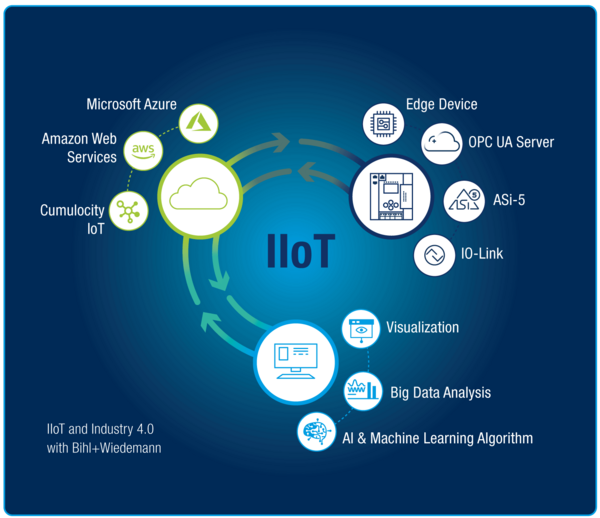

As early as the SPS fair in 2017, Bihl+Wiedemann introduced the first ASi gateways with integrated OPC UA interface, already anticipating today’s importance of a direct communication channel for vertical transmission of machine, process and diagnostic data. Because OPC UA makes it possible to collect, aggregate and make available the data for use by IT specialists for any kind of data analysis. Consequently, all of today’s ASi-5/ASi-3 gateways from Bihl+Wiedemann are equipped with an OPC UA server to enable fieldbus-independent direct data transmission between field devices and IT systems via AS-Interface. This allows the data to be used at various locations – in a visualization tool, a local server or in the cloud. No matter how the demands for implementing IIoT solutions evolve in the future, the gateways can also be expanded with additional interfaces such as REST API and MQTT on short notice.

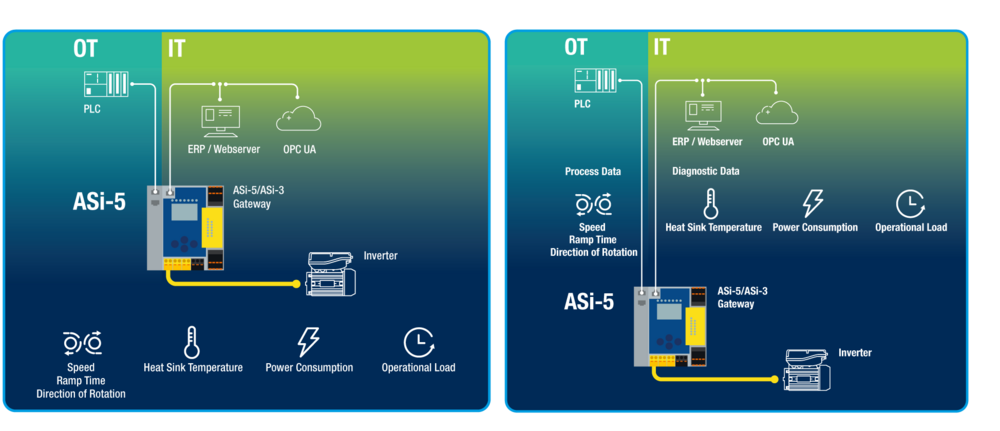

Different meanings of data for OT and IT

Modern manufacturing generates huge quantities of machine, process and diagnostic data, especially machines and systems where smart devices with IO-Link or ASi-5 interfaces and high data rates are employed. While these data can be transmitted fast and conveniently using the ASi-5 data shuttle, very few of them are directly useful for OT – controlling processes with a PLC – and thereby for transmission via a fieldbus.

The majority of the acquired machine data are needed, in fact, at a different location, namely in database systems of the IT, where these data are stored and analyzed – with these data in turn being accessed by applications such as preventive maintenance or for centralized ERP inventory management. For this reason – as well as out of consideration for data load and data speed in the fieldbus network – it makes complete sense to send OT and IT data in IIoT applications in parallel network structures.

The ASi-5/ASi-3 gateways from Bihl+Wiedemann are ready for this in their standard configuration: they have always provided two physically independent network interfaces – fieldbus and OPC UA – for separate transmission of data to OT and IT. Concerning the IT data, the gateway offers two options for sending via OPC UA: either an edge server prepares the data and sends it for example to a cloud like Microsoft Azure, Amazon Web Services (AWS) or Cumulocity IoT, or the cloud solution gets the data directly from the OPC UA server contained in the gateway. In both cases, the data are then available as valuable IT data in the cloud.

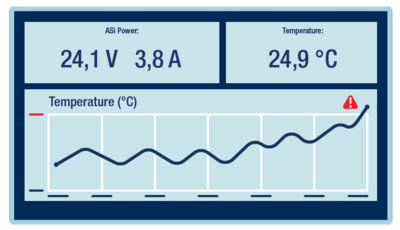

ASi-5/ASi-3 gateways provide their own diagnostic data

However, the ASi-5/ASi-3 fieldbus gateways from Bihl+Wiedemann are not just clever data switches for separating the data and distributing it over two networks – as smart components on the field level they are also able to independently generate their own diagnostic information over an ASi network for meaningfully supplementing the device data coming from the field. How many and which nodes are connected, how much current and voltage is present in the ASi network, whether the power supply is functioning properly, what errors have been reported – all questions that are important for both the OT and IT.

Drive technology example: OT and IT data on separate paths

One illustrative example of how ASi-5/ASi-3 gateways can function as smart data switches can be found in the drive systems for material handling. Here smart factory devices such as decentralized inverters or intelligent sensors with IO-Link make sense for both IT database systems and process control (OT). The latter is responsible for the motion of drives. This means it requires process data for the device such as the variable speed, the ramp time and the direction of rotation.

At the same time the IT systems can collect and evaluate diagnostic information such as heat sink temperature, power consumption or the operational load on the drive – and then for example use big data analytics, machine learning or AI algorithms to generate real added value. By monitoring load and current draw for example you can predict when a bearing of a drive will need to be replaced before it’s too late. As one can surmise from this example, the smart frequency inverter provides much more diagnostic data for IT systems than actual OT process data for the machine controller. To relieve the load on the OT with a fieldbus such as PROFINET and the real- time-critical data, the gateways employ a separate safe and established IT interface for sending the IT data using the integrated OPC UA server for data transport.

Maximum data security ensured

Likewise, this example shows that the IT data no longer move in closed network structures, but rather in open ones which are accessible over the internet and externally. This exposes Industry 4.0 devices to potential unauthorized data access and use as an attack platform – a risk which only increases with the degree of smart device networking. Therefore, Bihl+Wiedemann uses encrypted communication and authentication for its devices, which are designed for the highest level of data security while being easy to integrate into existing IT security concepts. Specifically, this means:

ASi-5/ASi-3 gateways from Bihl+Wiedemann can be updated to ensure their continued suitability for future security requirements.

The update servers use only signed firmware. The signature must be verified in addition by the devices.

Each TCP/IP capable device receives an individual certificate for SSL communication in the production process.

Customer-specific certificates for TLS (Transport Layer Security) are supported.

ASi as a fieldbus on the first automation level has no direct communicative transition between TCP/IP and the field devices. This separation provides additional security.

OPC UA uses established encryption procedures such as AES-256 with SHA up to 512 or RSA.

Software updates and OPC UA can also be blocked locally on the device – for reliable and absolute protection.

REST API and MQTT: additional options for sensor-cloud data exchange

OPC UA places the focus on industrial communication, with its technology immanent, high security standards providing great confidence for systems builders. Nevertheless, it is already evident that OPC UA will not remain the only interface format for the data exchange of edge devices like the ASi-5/ASi-3 gateways with higher levels. In order to continue to provide reliable data from the lowest field level to remote maintenance servers, visualization systems or cloudbased applications looking ahead to the future, the focus will be on at least two additional communication interfaces: REST API (Representational State Transfer – Application Programming Interface) and MQTT (Message Queuing Telemetry Transport). The REST API interface – probably familiar to every internet programmer – is often used for communication between servers or with programs and apps.

Due to its HTTP based client-server architecture it is also however useful for IT environments where machine data need to be used for web applications. The data can be used both live – for example, as a display on a web page – or can be included into a database. With MQTT, unlike OPC UA, the de vices are not organized hierarchically as senders and receivers, but can all communicate with each other asynchronously using publish/subscribe messaging, also known as pub/sub. Messages are sent by a publisher via a message broker and can be received by one or more subscribers. Such bidirectional communication does not exist among OPC UA servers. However, since this is often desirable, MQTT is integrated into OPC UA – as OPC UA pub/sub or OPC UA FX. At the same time, MQTT forms the communicative bridge between REST API and OPC UA. But no matter what the exact design of the interfaces will be: the current versions of the ASi-5/ASi-3 gateways from Bihl+Wiedemann are already well-prepared for this because both REST API and MQTT can be implemented in the devices on short notice as additional interfaces and supplements to OPC UA if the necessity arises.

IIoT and Industry 4.0 with Bihl+Wiedemann

Industry 4.0, Smart Factory and IIoT are becoming increasingly prominent in industry. Data is the most important raw material that must be collected, evaluated and transferred to OT and IT environments in an intelligent and efficient manner. The ASi 5/ASi 3 fieldbus gateways from Bihl+Wiedemann play an important role here, since in their dual function as interface and network node at the lowest field level they are the first line of access to the data from sensors and actuators and offer direct and future proof communication channels for data from the sensor to the cloud, both today and in the future.

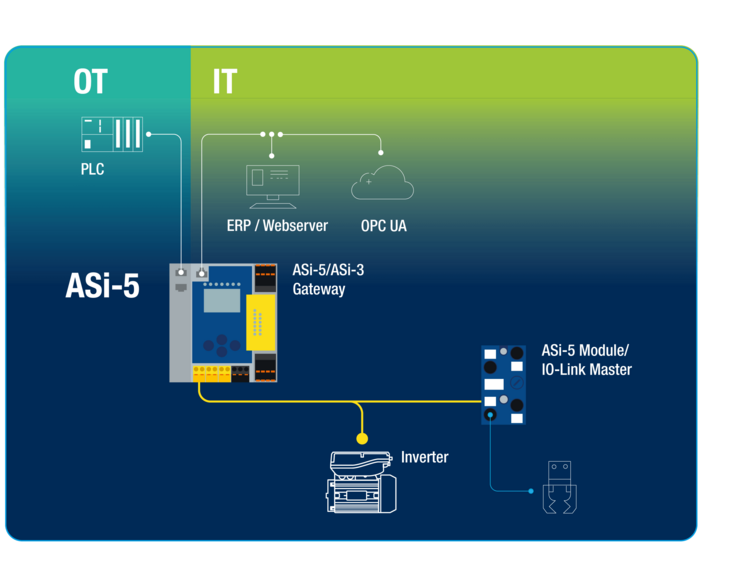

AS-Interface as collector and concentrator of IT data

ASi as a standardized fieldbus for the first automation level scores with its clever wiring concept. The network devices, including sensors and actuators, can be connected anywhere desired on the yellow profile cable using piercing technology. This simplified wiring effort also benefits applications not involving OT data but rather purely the collection and aggregating of IT data. Examples here would include the monitoring and documenting of temperature, relative humidity and other measurands in large production, warehousing and building complexes.

Here AS-Interface from Bihl+Wiedemann provides industry-proven components as well as an open system concept. With their interfaces, the ASi fieldbus gateways enable linking to a wide range of higher level IT systems where the data can be collected, evaluated and documented. At the same time ASi also offers openness to the field level, since field devices from different manufacturers are easy to connect and use with each other. No special solutions or modifications are required, nor is there any need for proprietary, often highly costly global solutions from corresponding vendors with all the technological implications.