- AS-Interface

- Safety

Safety solutions from Bihl+Wiedemann: custom tailored for mobile and modern material handling

The requirements of users and therefore also of machine builders are constantly changing, their wishes are in flux – and so is the material handling itself. Not least the extreme increase in online trade in recent years has meant that intralogistics solutions (must) become ever more flexible. Because when for example a small package needs to be transported from A to B, then a large one from B to C and finally a long roll from C to A, then such systems must also be able to handle this.

Flexibility is required in many areas: when connecting to ERP systems and IT for rapid implementation of the requirements, as well as when selecting the appropriate control system and safety technology. A simple E-Stop to shut down the material handling is no longer sufficient; here, programmable solutions and wireless safety technologies are increasingly important.

ASi-5 and ASi-3 are today standards in intralogistics – not least thanks to Bihl+Wiedemann. Based on the wiring technology AS-Interface, the company has for many years been offering a wide range of products and solutions for standard and safety technologies in intralogistics. The above-mentioned shift in material handling becomes especially notable in the field of mobile material handling technology – i.e. Automated Guided Vehicles (AGV), Autonomous Mobile Robots (AMR) or other autonomously navigating mobile shuttles and transport systems. Two topics are currently the focus of market interest here:

- How can multiple vehicles in an AGV system or even stationary machine modules that are simultaneously in a sudden, hazardous area be brought to a standstill together as quickly as possible and in a safety-compliant manner in the event of an emergency stop of a vehicle – keyword “global e-stop”?

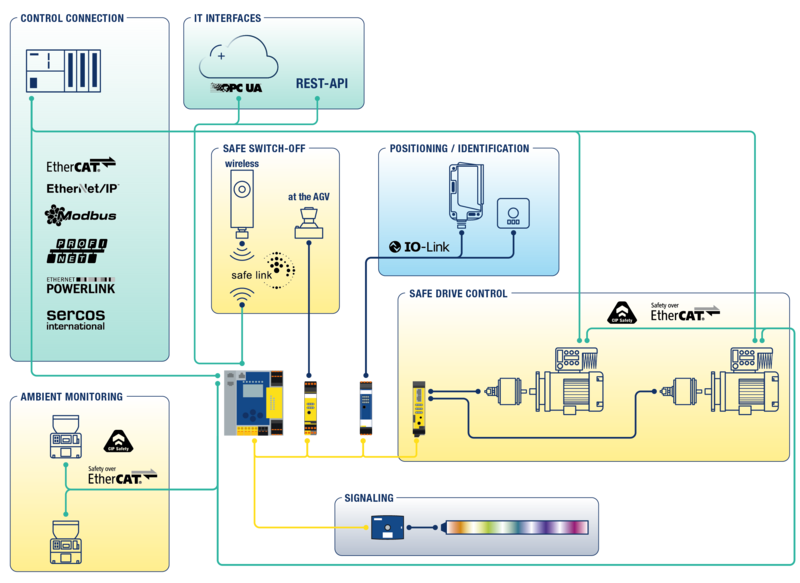

- What functionality and flexibility can safety-related control systems that have been specially developed for AGV and the like offer in terms of IT and OT integration or design?

Bihl+Wiedemann’s portfolio offers answers to these questions – with the communication technology Safe Link, which also offers wireless transmission of safe signals, as well as with solutions for the control and safety monitoring of driverless transport systems that can be individually adapted to specific communications and assembly requirements.

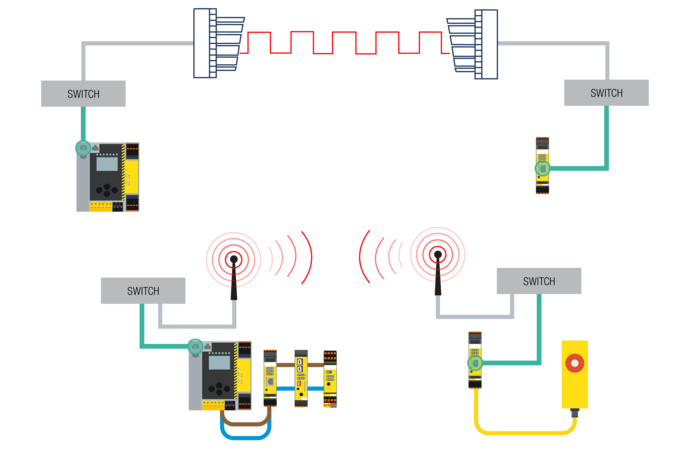

Global E-STOP: wireless and effective using Safe Link

To avoid imminent or actual hazards, power-driven work equipment – including not only stationary but also mobile machines such as AGV and AMR – must be equipped with one or more quickly accessible and conspicuously marked emergency command devices for safely stopping the entire work equipment.

This can be done using an emergency-off, whereby all electrical power is immediately switched off to stop a dangerous movement. However, the safety actuating element can also “only” trigger an emergency-stop – i.e. an immediate stop of the power-driven work equipment, whereby the power supply is still used for the targeted stopping of the dangerous movement and is only switched off after the machine has come to a standstill. But if the emergency-stop – of an AGV, for example – is not a local safety function, but a comprehensive – i.e. “global” – safety function that also applies to other Automated Guided Vehicles or machine modules, the question immediately arises as to which other vehicles and machines are affected.

And, above all, how the mobile units can be “quickly reached” in a safety-compliant manner in accordance with the Machinery Directive or the forthcoming Machinery Ordinance. The same applies if several vehicles are to be stopped by emergency-stop from a central operating station. The answer is provided by the communication technology Safe Link from Bihl+Wiedemann.

This also enables wireless Ethernet-based coupling via WLAN, 5G or other standards and therefore safe networking of mobile units with each other and with stationary machine modules – even if different control systems and fieldbus protocols are used. This is how Safe Link ensures that a global emergencystop function is established, with which safe signals can be transmitted promptly in the overall system network and affected units can be reached quickly. If an emergencystop control element is actuated anywhere, both system components and wirelessly integrated AGV can be switched off.

This communication technology is now standard in all current gateways and Safety Basic Monitors from Bihl+Wiedemann, making networking with Safe Link child’s play.

Controlling AGV with versatile function and communication options

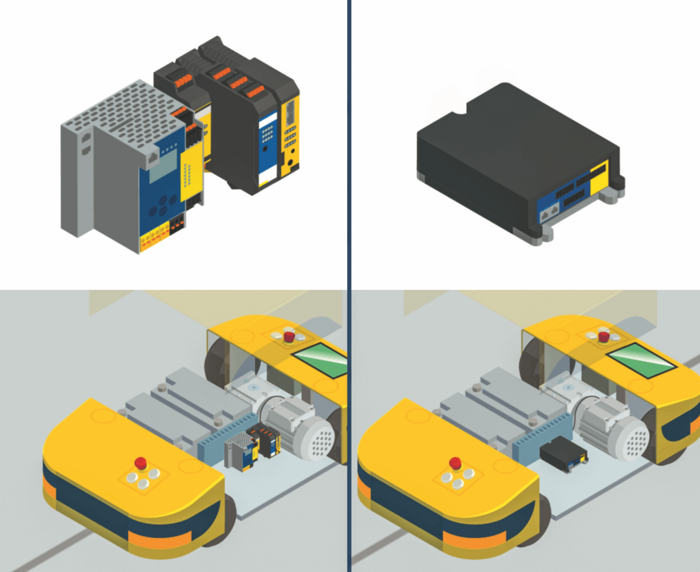

Another new area of application that can now be realized with the large safety modular system from Bihl+Wiedemann is the control of Automated Guided Vehicles (AGV), Autonomous Mobile Robots (AMR) or other autonomously navigating mobile shuttles and transport systems. Adaptable to individual customer requirements, these solutions enable the integration of a wide range of safety functions such as the integration of safety laser scanners and emergencystop control elements or safe speed monitoring without any additional safety control.

They can also be used to support the actual vehicle control system, AGV drive technology and sensor-based navigation and localization systems. On the communication side, important relevant connectivity requirements such as analog I/Os and safe digital outputs, ASi-5/ASi-3, EtherNet/IP, CANopen, ASi Safety, CIP Safety over EtherNet/IP and, of course, Safe Link are also met.

Since a range of other fieldbus options for standard and safety communication are available within the Bihl+Wiedemann safety portfolio, and many vehicle manufacturers have special requirements for the OT and IT connection, connection types or the size of control units, safety solutions for AGV with ASi-5 and ASi-3 from Bihl+Wiedemann can also be optimized or redesigned in individual configurations, dimensions and other technical details. It is also possible to implement standard functions, such as integrating intelligent sensors like RFID solutions or controlling LED strips for indicator and brake lights on the vehicle.

This last point in particular shows another advantage of AS-Interface: the ability to pre-process, which helps to reduce the workload of the AGV control. Complex details, such as the indicator behavior of a RGB module, can be set in advance in the software suite ASIMON360 and then easily called up as required. The overall process is controlled by the decentralized logic of the corresponding module.

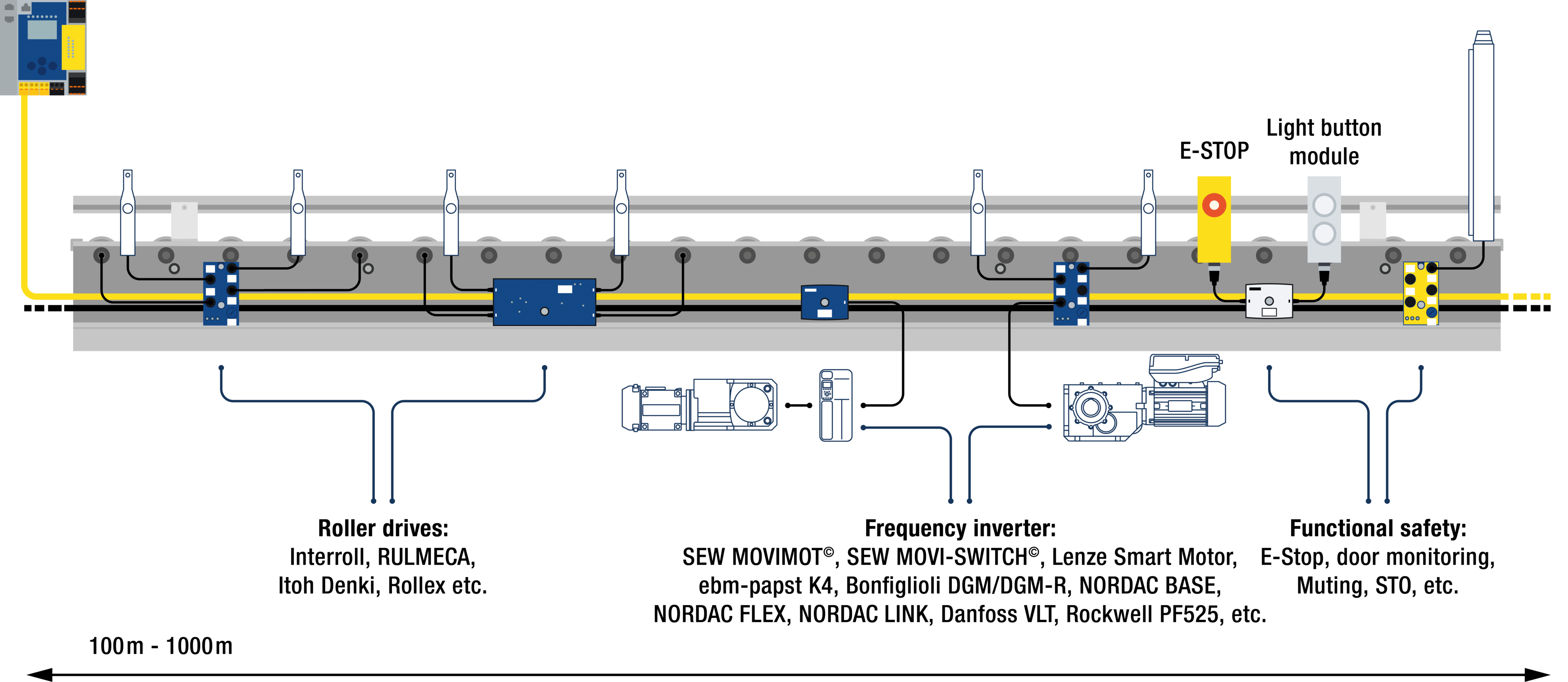

Drive solutions for material handling

Ideal areas of application for AS-Interface are not limited to mobile units, but also include stationary drive and conveyor systems for material handling machines and plants. Because the advantages of the simple wiring system ASi, such as

- Connection of sensors, actuators and ASi modules thanks to piercing technology without the need of connectors and pre-assembled connection cables

- Power supply and communication usually both on the same reverse polarity protected profile cable

- Transmission of safe and standard signals on the same cable, as well as

- Free choice between line, ring or star topology for system layout

are also evident in the areas of warehousing and material handling, conveying and sorting equipment, shuttle pallet warehouses, order picking systems, packaging equipment as well as storage and retrieval machines.

ASi-5 and ASi-3 as well as the corresponding safety protocols ASi-5 Safety and ASi Safety at Work can be easily combined in one application in order to perfectly meet the respective requirements. For example, ASi-3 Modules from Bihl+Wiedemann are ideal for the especially cost-effective integration of drives into an ASi application as well for the transmission of individual binary signals, e.g. from light barriers.

The newer and more powerful ASi-5 technology makes it possible to transfer serial protocols between motor modules and drives in addition to digital or analog controls. Since IO-Link and soon IO-Link Safety are perfectly integrated into ASi-5 and ASi-5 Safety, you can also easily integrate drives and identification systems such as barcode or RFID readers with an IO-Link interface.

Using their intimate familiarity with the advantages and possibilities of AS-Interface, Bihl+Wiedemann is always able to implement special solutions. These include programmable software for the Zero Pressure Accumulation conveying of unit loads as well as ASi-5 Cable Duct Modules for cost-effective control of two or four motorized rollers. Bihl+Wiedemann also offers special ASi-5/ASi-3 all-in-one solutions in its range for drives from leading manufacturers, including motorized rollers from Interroll, Itoh Denki and RULMECA, DC motors from ebm-papst and frequency inverters from SEW-EURODRIVE, NORD DRIVESYSTEMS, Danfoss, Rockwell, Lenze and Bonfiglioli, among others, which take both technology standards into account.

Fast, flexible, safe and economically efficient material flow processes will continue to be in demand in a constantly changing intralogistics sector. With an ASi-5/ASi-3 portfolio and expertise in automation and safety technology as well as conveyor and drive technology, Bihl+Wiedemann is ideally equipped to meet these challenges.