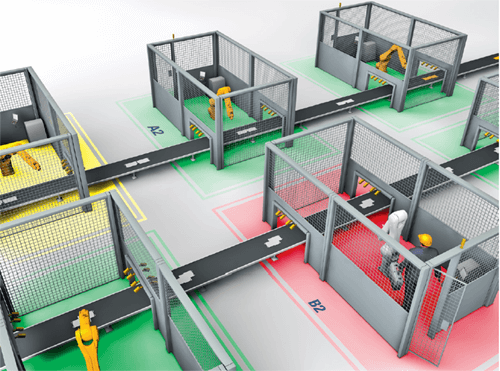

Selection of mode of safe operation - flexible to use, easy to configure

Jochen Bihl explains how a certified module from Bihl+Wiedemann makes "Selection of mode of safe operation" easier. Using a standard HMI users can safely select up to 5 different operating modes for a maximum of 6 system parts – each with individualized safety functions. Configuring the operating modes is very simple thanks to the ASIMON360 configuration software. The Euchner EKS electronic key system allows access to be restricted to authorized groups of persons.

Video length: 2:34

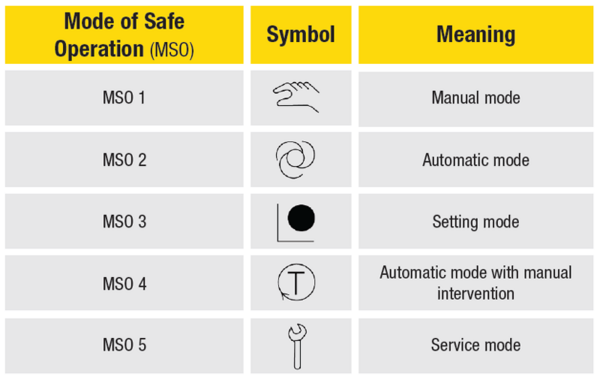

Today's complex machines need the ability in certain situations to permit an operating mode at reduced speed or without monitoring of certain protective devices. This is now possible using so-called “Selection of Mode of Safe Operation.”

Bihl+Wiedemann makes it possible to easily implement Selection of Mode of Safe Operation up to PLe, with maximum convenience for the end user over a standard HMI. The access authorization for safe operating mode selection is supported via the Euchner EKS electronic key system.

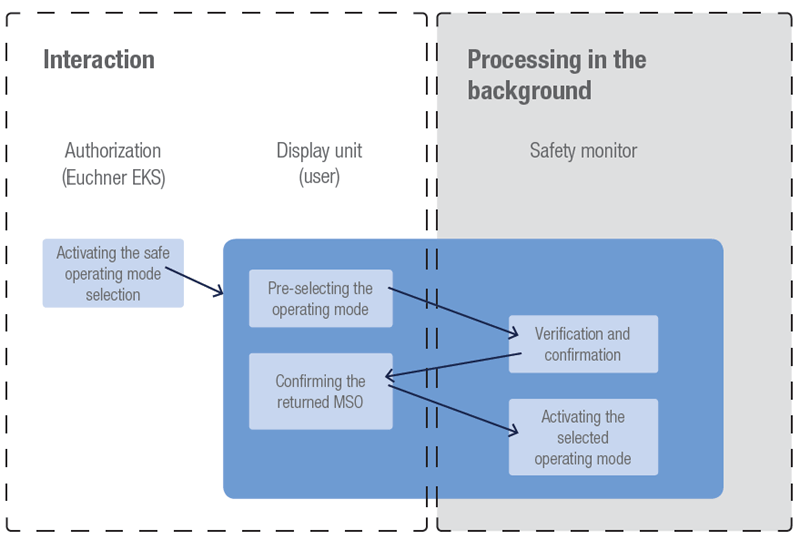

Principle of the Selection of Mode of Safe Operation

The operating mode can be safely selected and activated using a standard HMI such as a touch panel. Access to this selection is restricted to the authorized group of persons by the Euchner EKS electronic key system.

Highlights of the Selection of Mode of Safe Operation

- Safe operating mode selection over a standard HMI, e.g. a touch panel

- Unrestricted configuration of five safe operating modes in six different instances

- Simple implementation using a TÜV certified function module in the configuration software ASIMON360

- Communication and detailed diagnostics made convenient via OPC UA (or also fieldbus)

- Up to Performance Level e

- Integrated into all newsafety monitors from Bihl+Wiedemann

Safe procedure

- Displayed are the operating modes which can be activated with the current authorization.

- Clicking on an activatable operating mode pre-selects it.

- The pre-selection verified by the Safety Monitor is shown to the user for confirmation.

- Confirming the pre-selection by clicking on it safely activates the corresponding operating mode in the Safety Monitor.

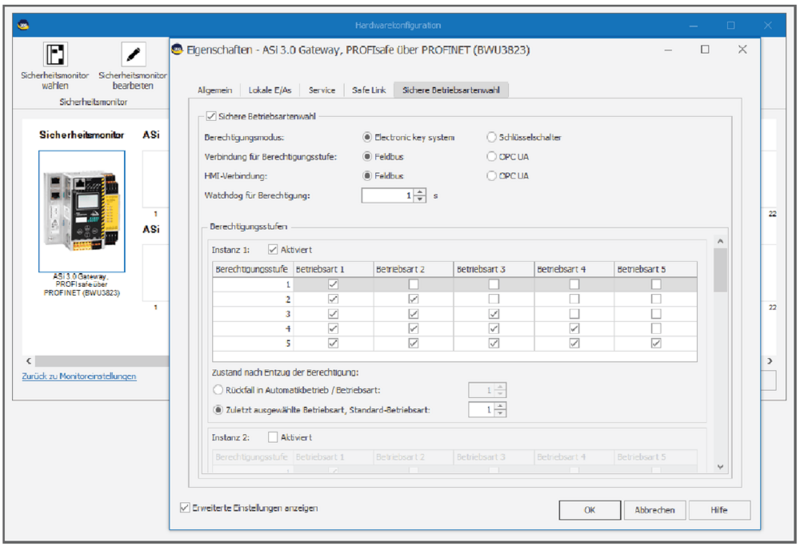

Simple configuration in ASIMON360

- Activation of the Selection of Mode of Safe Operation in the ASi master

- Allocation of the selectable operating modes to a maximum of five different electronic key levels (for EKS)

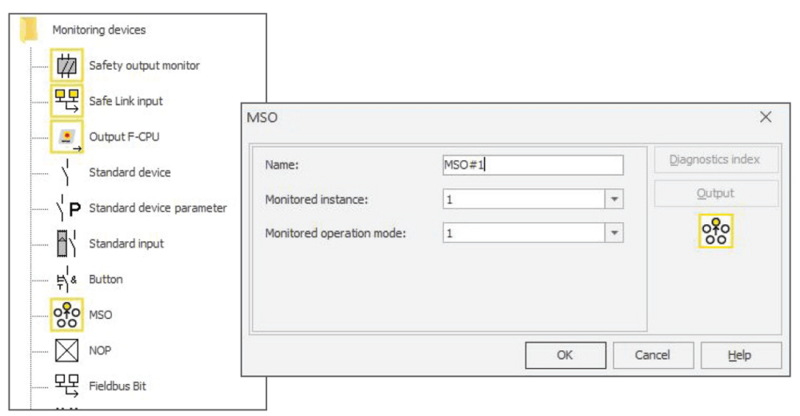

- Unrestricted use of the MSO (Mode of Safe Operation) module within the safety configuration

Full flexibility for your machine

- Five different operating modes with different safety functions are freely configurable

- Independent, centralized configuration of up to six different instances, e.g. for six different system parts

This way, you can set different system parts independently to different operating modes.

Functional safety

Learn how to seamlessly integrate safe sensors and actuators as well as safety monitors into all common automation systems with ASi Safety. Safe and unsafe signals can be transmitted on the same line.

PLC independent safety technology

Discover the advantages of our safety and wiring technology, which is system and manufacturer-neutral. In this way, it enables simple, fast and thus cost-effective commissioning.

Muting

Discover how easy muting is with Bihl+Wiedemann's muting modules. All signals required for muting can be connected to a single module.

Speed monitoring

Discover an effective way to safely evaluate sensors or rotary encoders by means of our speed monitors. For example, a safe reduced speed can be achieved for setup operation.