- Technology

- Application

- Safety

ASi-5 SAFETY – ALWAYS THE SAFE DECISION

Significantly improved bus capacity initiates changeover

When developing ASi-5, the topic of safety technology was an integral part from the very beginning – in contrast to ASi-3, for which the technological framework was not yet present. This is why work on the ASi-5 Safety Stack, for example the transmission mechanisms and protocols, was already completed when the ASi-5 specification was presented at the end of 2018.

Certification of the ASi-5 Safety Monitor Reference firmware for use in ASi-5 safety monitors and ASi-5 safety nodes by TÜV NORD took place in January 2019. By this, the stage was set for the development of the first I/O modules and safety monitors with which safe and non-safe ASi-5 signals can also be collected cost-effectively in the field and integrated into fieldbus environments.

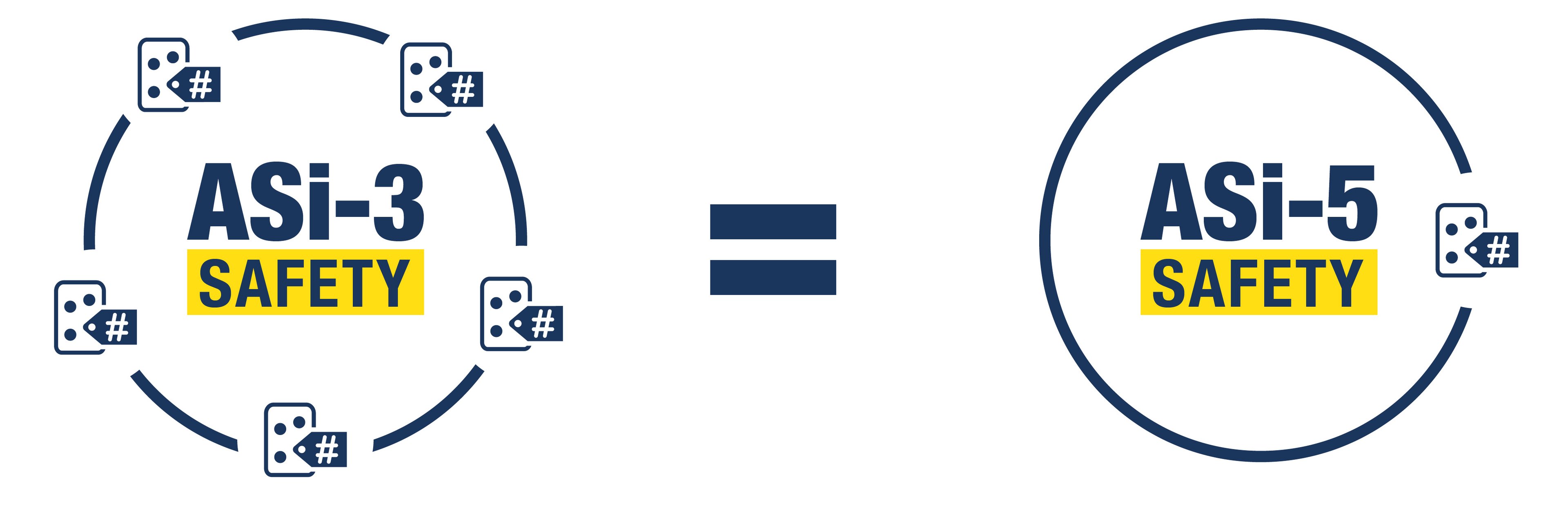

ASi-3 experts especially have identified the most important feature for them in the new ASi safety generation: the vastly improved bus capacity. Whereas ASi Safety at Work requires each safe input and each safe output to have its own separate address, the safety technology of ASi-5 now makes it possible to use just one address in both directions for up to 16 safe bits and additional non-safe signals.

In practice, a lot of addressing capacity can be "freed up" for new safety devices by specifically replacing existing, safe ASi-3 I/Os with corresponding ASi-5 safety modules. That way, additional safe and non-safe signals can be integrated into existing applications, especially in those that were previously fully utilized. And in completely new projects, this efficient bus utilization in project planning saves many I/O modules - and thus space and costs.

Complexity in the background – as easy to operate as ever

High transmission speed, great data bandwidth, the highest bus utilization, a variety of diagnostic functions, future-proof – everything that applies to ASi-5 in standard applications does as well to ASi-5 Safety. And with it, simplicity and clarity in operation - even though the technological complexity in the background has increased significantly.

True to the motto "good technology becomes even better when it is easy to use", Bihl+Wiedemann always thinks about the users and their working methods, which they have acquired while working with ASi-3. For example when configuring ASi-5 Safety using the safety software ASIMON360, there is hardly a difference with respect to the user experience. Whether hardware configuration, addressing, project planning or commissioning of safe ASi networks – everything follows familiar operating routines.

The user friendliness and user experience have remained unchanged, the magic of the new possibilities takes place in the background. The same applies to the product innovations that Bihl+Wiedemann will launch on the market in the course of 2022.

New safety I/O modules for mixed infrastructures

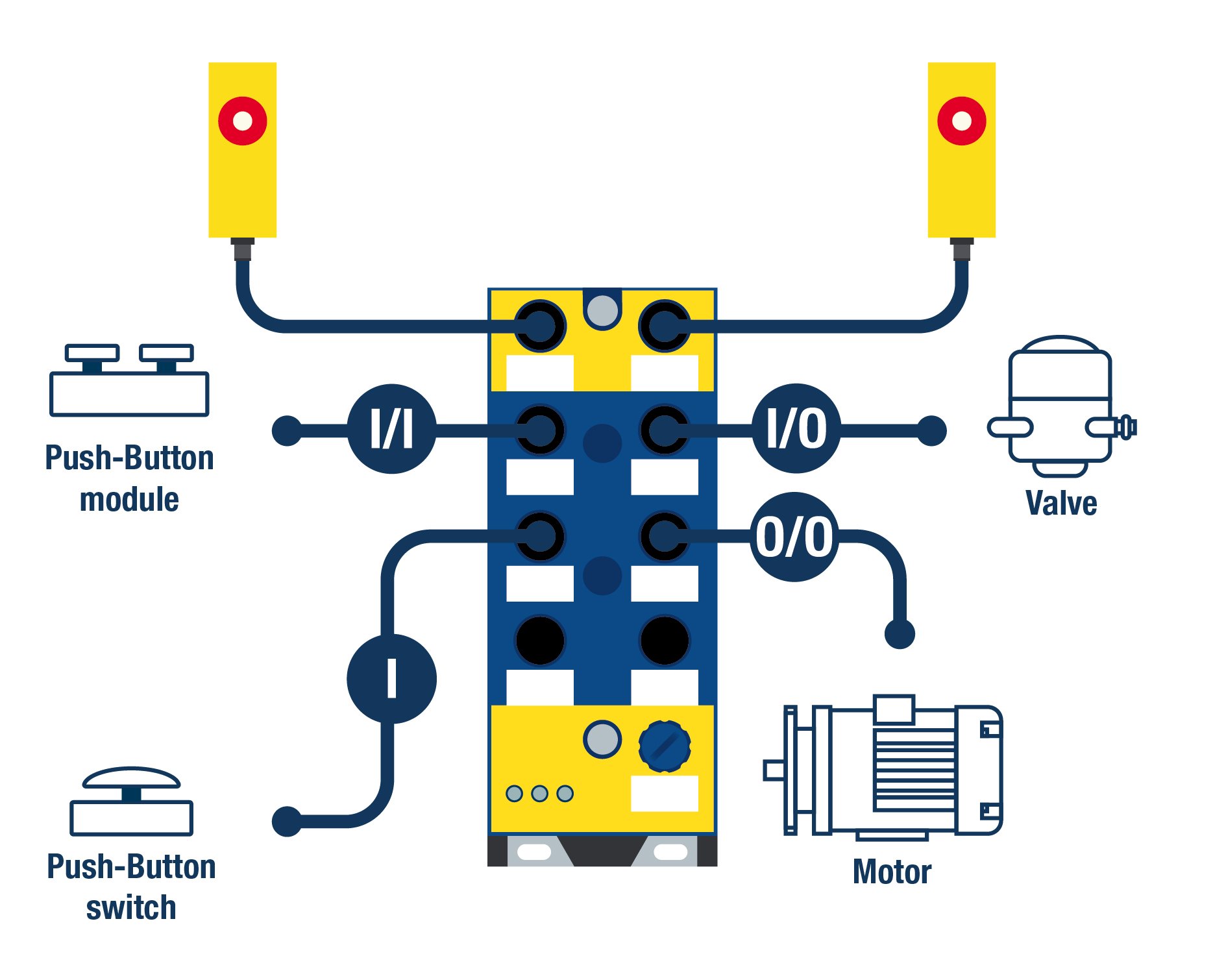

The Mannheim-based company now has more than three years of experience with ASi-5 on the market. Many of the projects successfully implemented during this time have shown that customers often want to collect both safe and standard signals together in the field - and do so as cost-efficiently as possible.

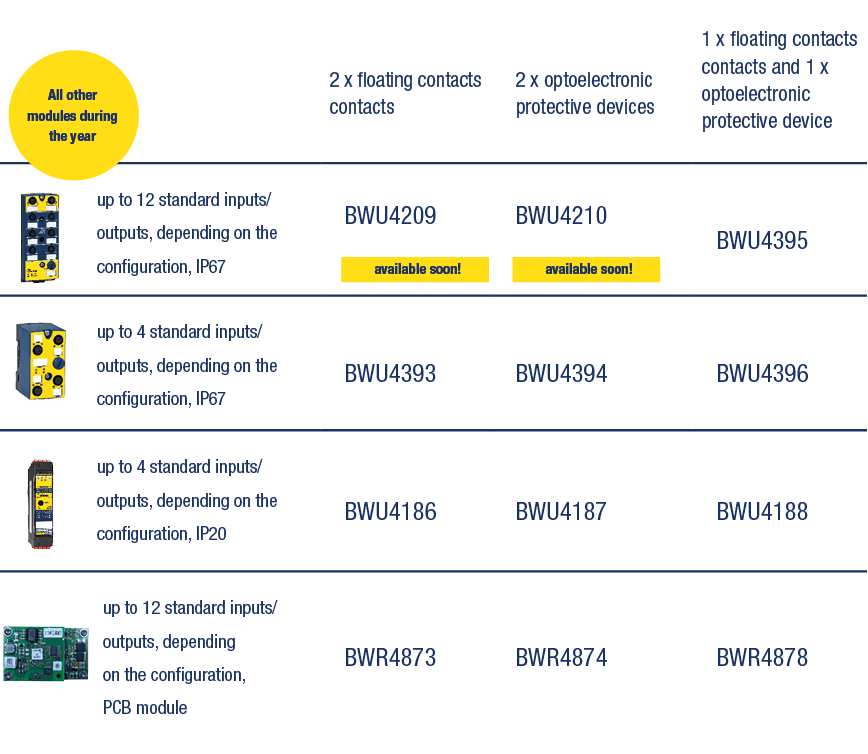

This is why Bihl+Wiedemann is using ASi-5 Safety technology now as the basis for starting with a series of new safety I/O modules which takes these mixed infrastructures into account. The modules will be available in variouos configurations with respect to design, version and combination of safe I/Os as well as the number of non-safe inputs and outputs.

Already available are two ASi-5 Safety input modules: one with two safe floating contacts (BWU4209) and one with two OSSDs (BWU4210) for optoelectronic protective devices – both in IP67 housing and with 12 standard I/Os.

By the end of 2022 the range will have been appropriately expanded, with one model each for two floating contacts, for two optoelectronic protective devices and for the combination of floating contact/OSSD in the following versions: as IP67 field module with four additional standard in- and outputs, as IP20 control cabinet module, IP67 field module and circuit board module with 12 additional standard in- and outputs each. The latter was designed for example for installation in fixed or pivoted control panels to provide the most space-saving integration option for ASi-5 Safety.

Generation change for ASi-5/ASi-3 Safety Gateways

Also on the Bihl+Wiedemann agenda for 2022 is the market launch of a new gateway family. Among the new possibilities these devices offer the fully digital documentation of a complete ASi-5 Safety project that has been configured and parameterized in the gateway using ASIMON360. This means that in the future, hardware configurations and device parameterizations will be available directly on site in the field - as a digital twin of the version on a server, so to speak - and will no longer have to be searched for in the IT system at great expense if necessary. This is helpful for example when after several years a service technician – often from outside the company – needs to work on the plant and then can access all the relevant project data on-site without wasting time.

Maintenance and repair work is thus significantly accelerated - and automatically stored in the documentation. And when designers are working together on a common project, the work is simplified when all can access the same and consistent data in the gateway. And the cloning and copying of projects to other gateways will also be possible with the new gateway generation.

ASi-5 Safety – the perfect partner for ASi Safety at Work

Even today, an estimated four out of five safety-related applications tend to be less complex. Often, only a two-channel safe single signal needs to be collected and transmitted - for example from an E-STOP button. And ASi Safety at Work is still perfect for such cases. Here ASi-5 Safety is not essentially superior, being neither better nor cheaper. But things look different when multiple safe signals or a combination of safe and non-safe signals need to be transmitted.

The new ASi-5 Safety Modules from Bihl+Wiedemann provide, as mentioned above, both safe and non-safe I/Os and thereby contribute to considerable cost savings – especially since these modules from Bihl+Wiedemann are now even 10 percent more expensive than pure ASi-5 modules without safety technology. On the other hand, the complementary character of ASi-5 Safety becomes apparent when the signals of complex products are to be collected.

In the future IO-Link Safety devices, when they are available, will be able to be integrated into ASi networks without limitations. By means of gateways, they can then be integrated into higher automation levels where safety functionalities are also implemented. In both scenarios ASi-5 Safety with its high speed and great data bandwidth along with its expanded diagnostics is an ideal fit with ASi Safety at Work – just as ASi-5 can complement ASi-3 in standard applications.

To sum up: For the majority of safety applications, ASi Safety at Work is still the ideal solution today and in the medium term, because it is simple and cost-effective. But when no longer dealing with safety-relevant standard applications, but rather with implementing more complex applications or collecting numerous safe and non-safe signals in one location, ASi-5 Safety now provides an economically and technologically perfect addition.

In the future, ASi-5 Safety will offer all the advantages that have already made ASi-5 the perfect partner for ASi-3 in standard applications. Of special note are the great data bandwidth and faster transmission speed – prerequisites for integrating intelligent sensors and actuators such as IO-Link devices and, in the future, also IO-Link safety devices or the implementation of more complex applications and projects.