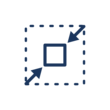

Safety solution for AGVs – versatile, cost-effective, safe communication with each other

Do you have unique requirements for your automated guided vehicle (AGV)? With our wide range of standard and safety technologies, we can implement your requirements quickly and easily. Our customized safety solution not only includes many safety criteria such as the integration of safety laser scanners, Emergency STOP buttons or the safe evaluation of positions and speeds. It also offers solutions for orientation, signaling and drive technology as well as support for AGV control. This enables all AGVs, for example, to be switched off centrally by a safe emergency stop signal – very easily via LAN, Wi-Fi, 5G and much more.

The most important AGV-relevant safety functions – such as the integration of safety laser scanners, E-stop buttons, or the safe evaluation of positions and speeds – can be realized very easily and without additional safety control with the safety technology from Bihl+Wiedemann. Moreover, this solution also offers many different building blocks for other non-safety-related functions, such as signaling, drive control, and even support for AGV control.

Large safety

construction kit

We put together an optimum solution for your AGV from a wide range of safety technologies, e.g. for connecting the safety laser scanner from SICK. Our solution can also support the actual vehicle control system, AGV drive technology and sensor-based navigation and localization systems.

Fieldbus-independent

communication

Our range of solutions for AGVs enables safe data e.g. via PROFIsafe, CIP Safety, Safety over EtherCAT, openSAFETY, Safe Link and ASi. Communication via PROFINET, EtherNet/IP, Modbus TCP, EtherCAT, CANopen is also possible.

Safe

Link

Cost-effective, safe data exchange between AGV transport systems and with stationary machine modules via Ethernet, 5G or WLAN– even when using different control systems and fieldbus protocols. Safe Link thus enables a global emergency stop function.

Functional safety

Learn how to seamlessly integrate safe sensors and actuators as well as safety monitors into all common automation systems with ASi Safety. Safe and standard signals can be transmitted on the same line.

Selection of Mode of Safe Operation

Read all about how our TÜV-certified device facilitates "selection of mode of sfae operation selection": A standard HMI allows you to safely select up to 5 different operating modes for a maximum of 6 plant sections – each with unique safety functions.

PLC independent safety technology

Discover the advantages of our safety and wiring technology, which is system and manufacturer-neutral. In this way, it enables simple, fast and thus cost-effective commissioning.

Muting

Discover how easy muting is with Bihl+Wiedemann's muting modules. All signals required for muting can be connected to a single module.