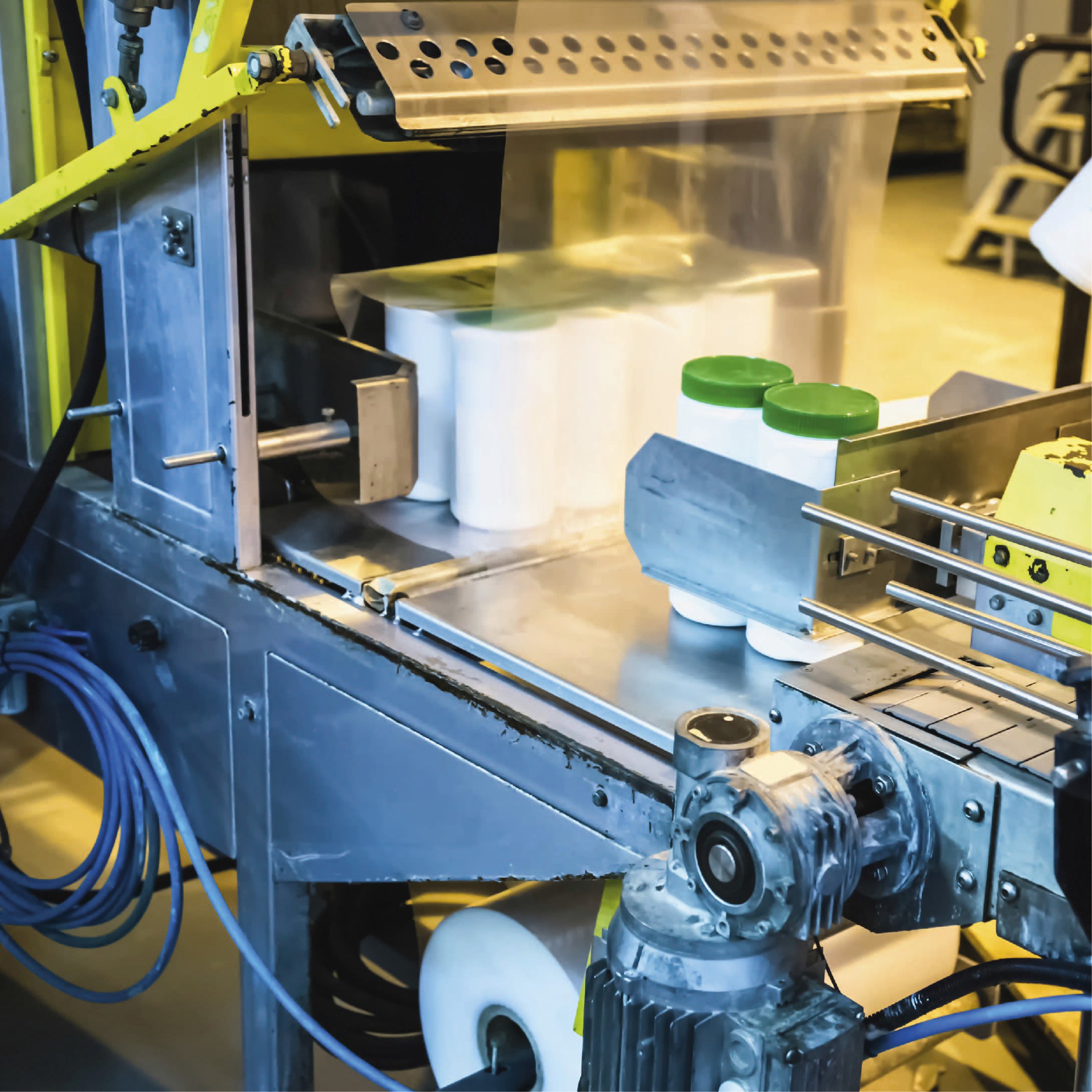

Packaging Automation with Bihl+Wiedemann

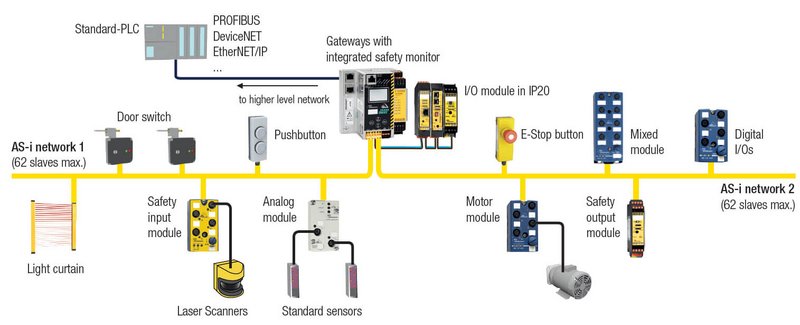

Increasing the productivity of machines and systems is of great importance, for manufacturers of packaging machines. This requires flexible and innovative solutions. Bihl+Wiedemann offers the right components for safe packaging automation with AS-Interface, while also allowing sustained optimizing of costs and processes.

All of our components/systems satisfy the new Machinery Directive 2006/42/EC and are easy to integrate into your documentation/calculation using readily available devices of the Sistema library.

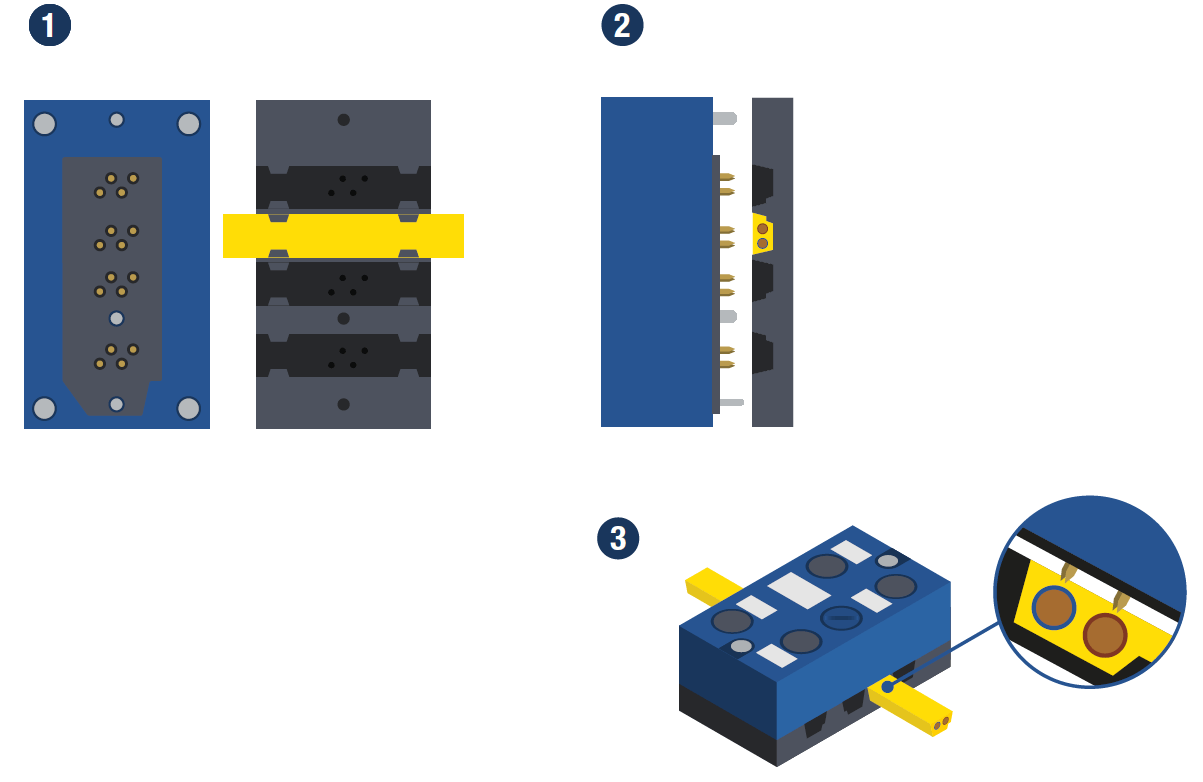

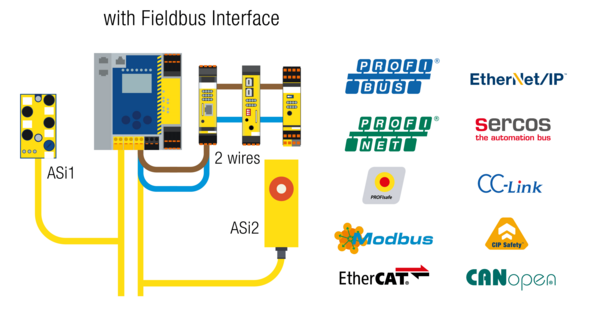

Data and Power on One Cable

ASi connects the modules in the lowest process level in automation systems with each other. The usual cable harnesses are replaced by a single electrical cable – the ASi cable. Both data and power are transmitted on this one cable.

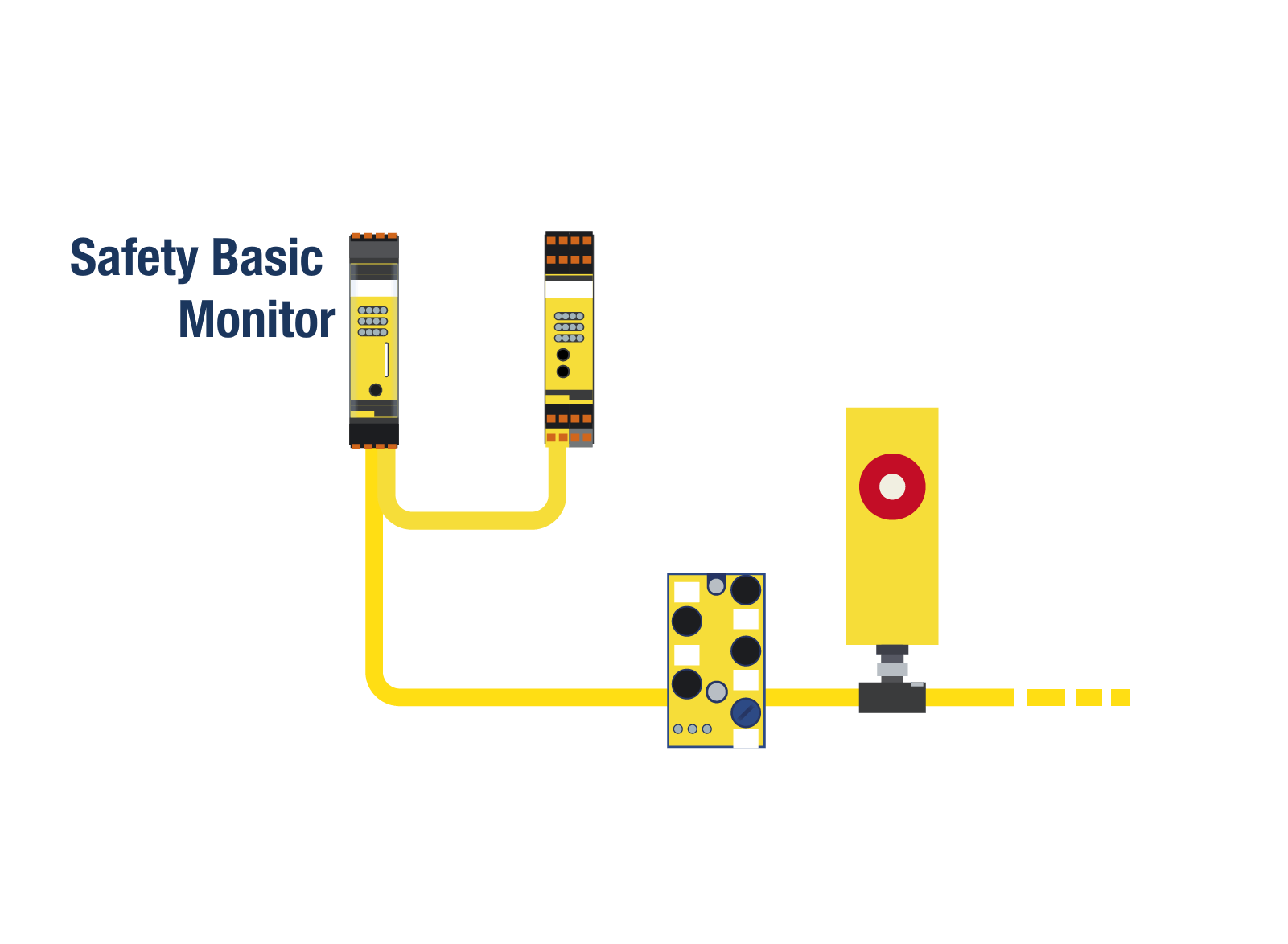

Safety Basic Monitor

For small applications with three or more safe signals, we offer the Safety Basic Monitor, a safe small control without gateway, but with configurable signal outputs. The ASi Safety Module is universally expandable and is also suitable as a head station for special safety applications.

Cost-effective variant for small applications

Safe small control

Wide function range

Easily expandable via AS-Interface

Easy to integrate into existing systems

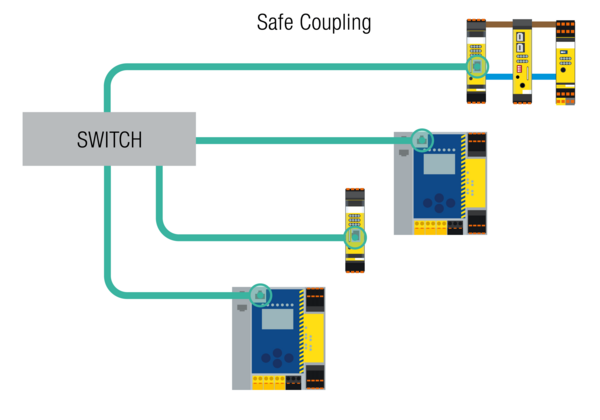

Simple coupling to other systems

Programmable via PC

Max. 31 safe modules per device

Narrow width Safety Basic Monitor: 22.5 mm

Increasing productivity in packaging technology through:

- Sustained process optimization

- Sustained cost optimization

- Safety in packaging automation