Speed monitoring

Speed monitoring – extremely compact and cost-efficient

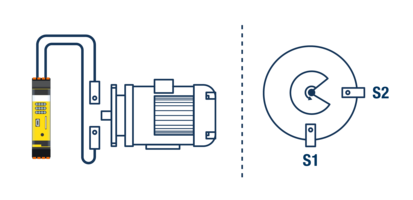

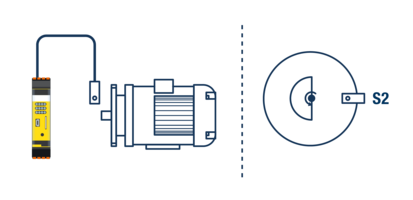

Safe speed monitors for sensors/initiators: Safety Basic Monitors

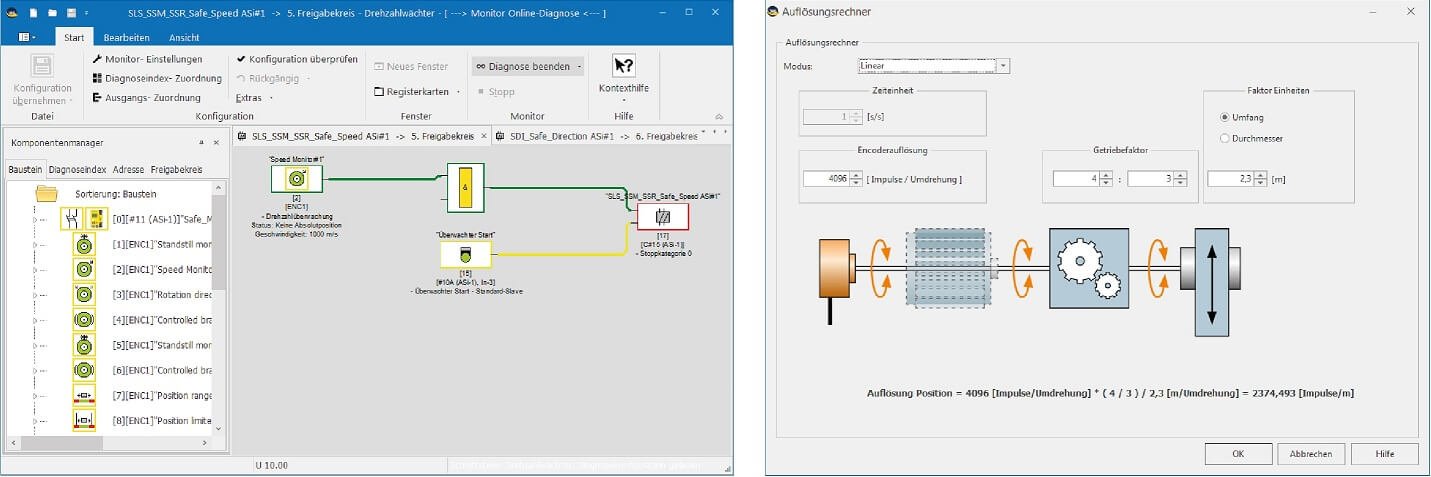

- Autonomous compact safety controller

- 4 × 2-channel safe inputs or standard inputs and status outputs

- Speed monitor on the local inputs

- 2 axes 2-channel (SIL2, PLd) or SIL3, PLe)

- 4 axes 1-channel (SIL1, PLc)

- Standstill monitor on the local inputs

- 4 axes 2-channel (SIL2, PLd)

- 2 safe electronic outputs

- USB or Ethernet interface for configuration

- Detailed diagnostics and shut-off history via software or control

- Chip card for easy device exchange

And all in one unit with just 22.5 mm installation width

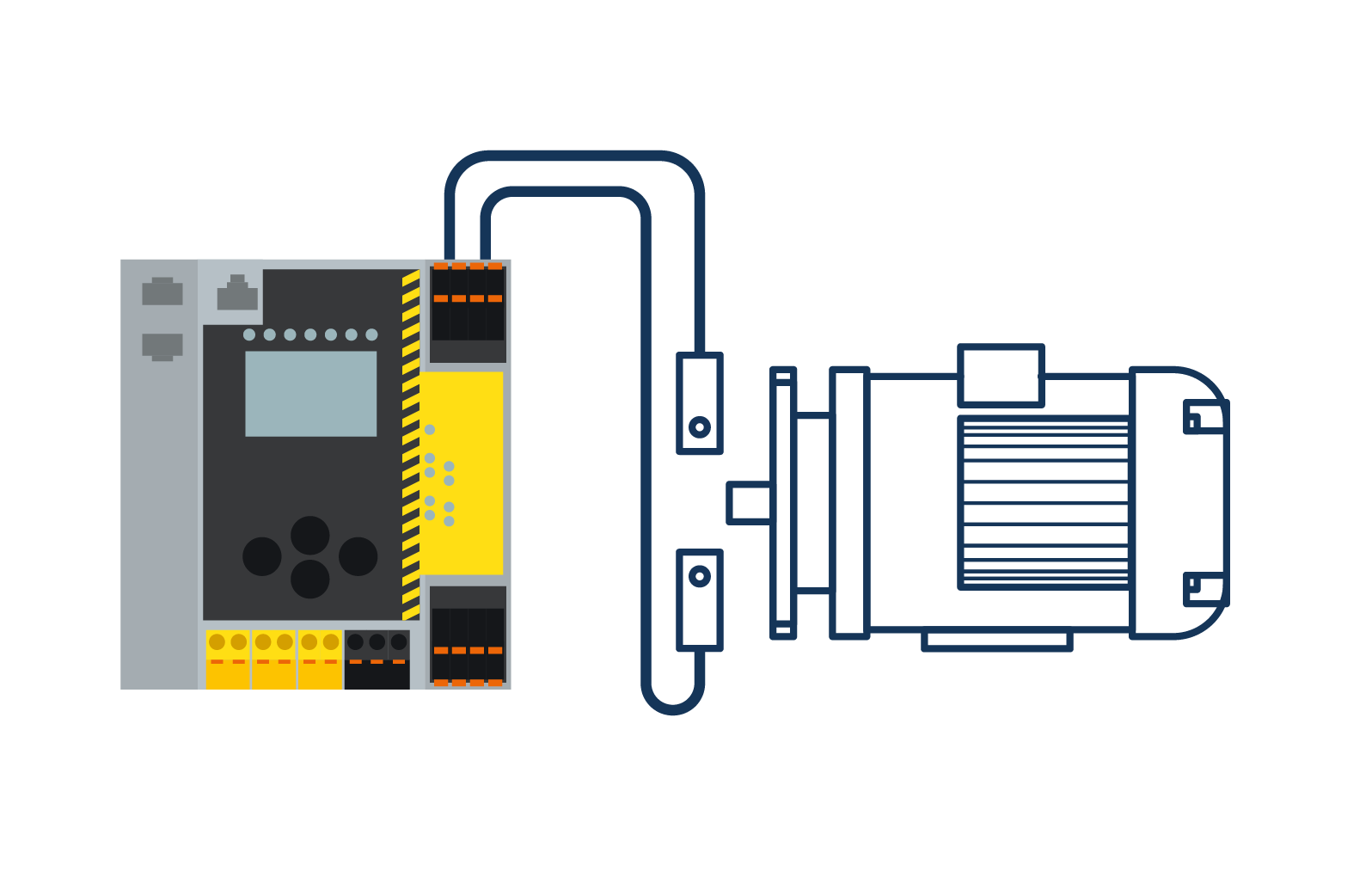

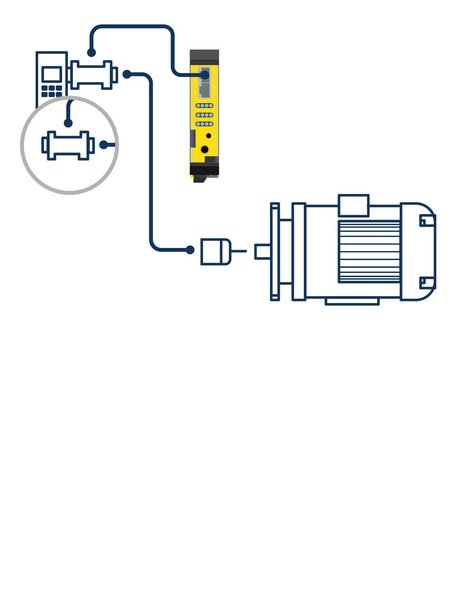

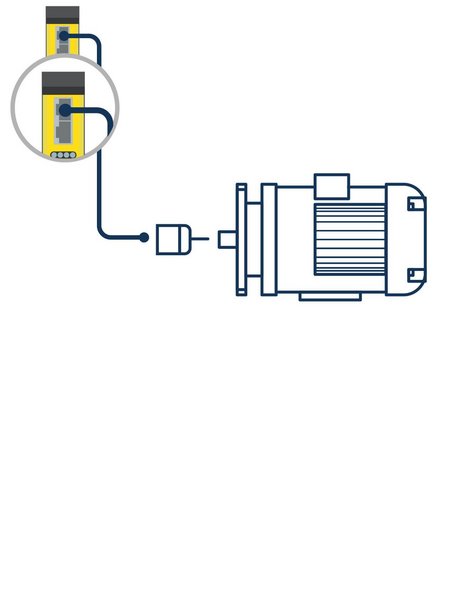

Simple connection

Adapter modules for simple connection between the frequency inverter and encoder cable

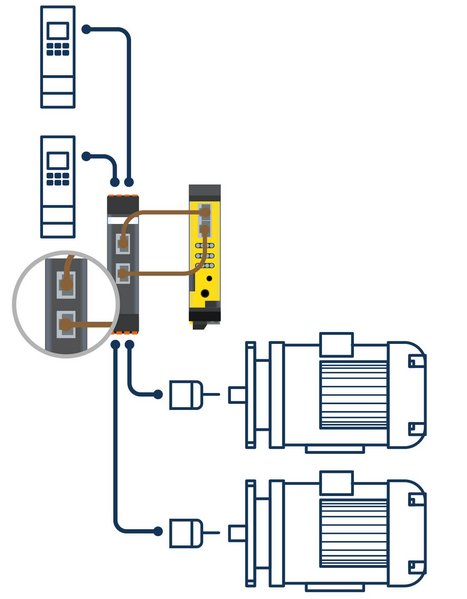

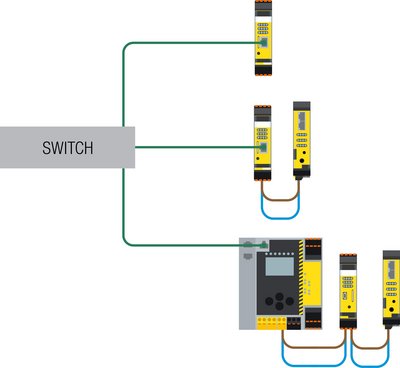

Functional safety

Learn how to seamlessly integrate safe sensors and actuators as well as safety monitors into all common automation systems with ASi Safety. Safe and unsafe signals can be transmitted on the same line.

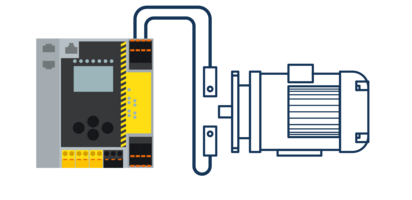

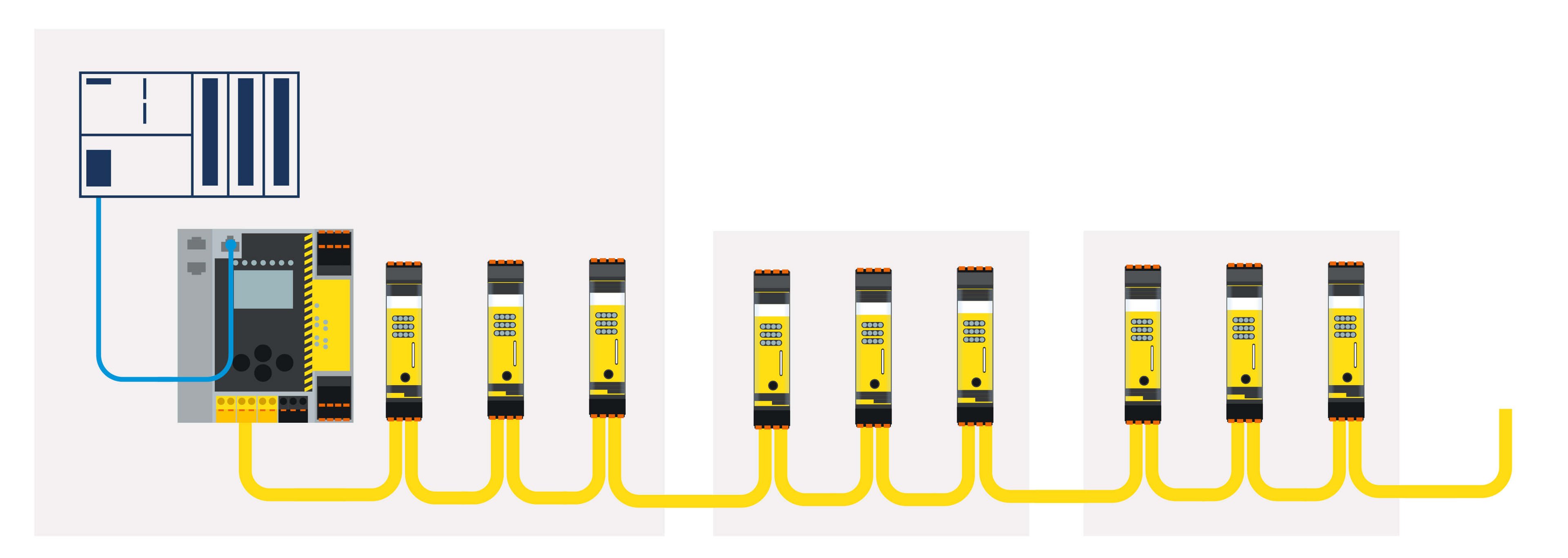

PLC independent safety technology

Discover the advantages of our safety and wiring technology, which is system and manufacturer-neutral. In this way, it enables simple, fast and thus cost-effective commissioning.

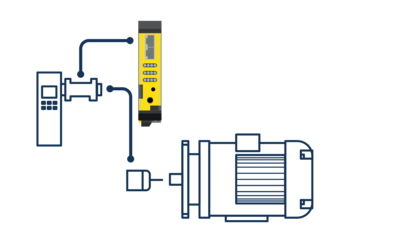

Selection of Mode of Safe Operation

Read all about how our TÜV-certified device facilitates "selection of mode of sfae operation selection": A standard HMI allows you to safely select up to 5 different operating modes for a maximum of 6 plant sections – each with unique safety functions.

Muting

Discover how easy muting is with Bihl+Wiedemann's muting modules. All signals required for muting can be connected to a single module.