Drive solutions for Rockwell

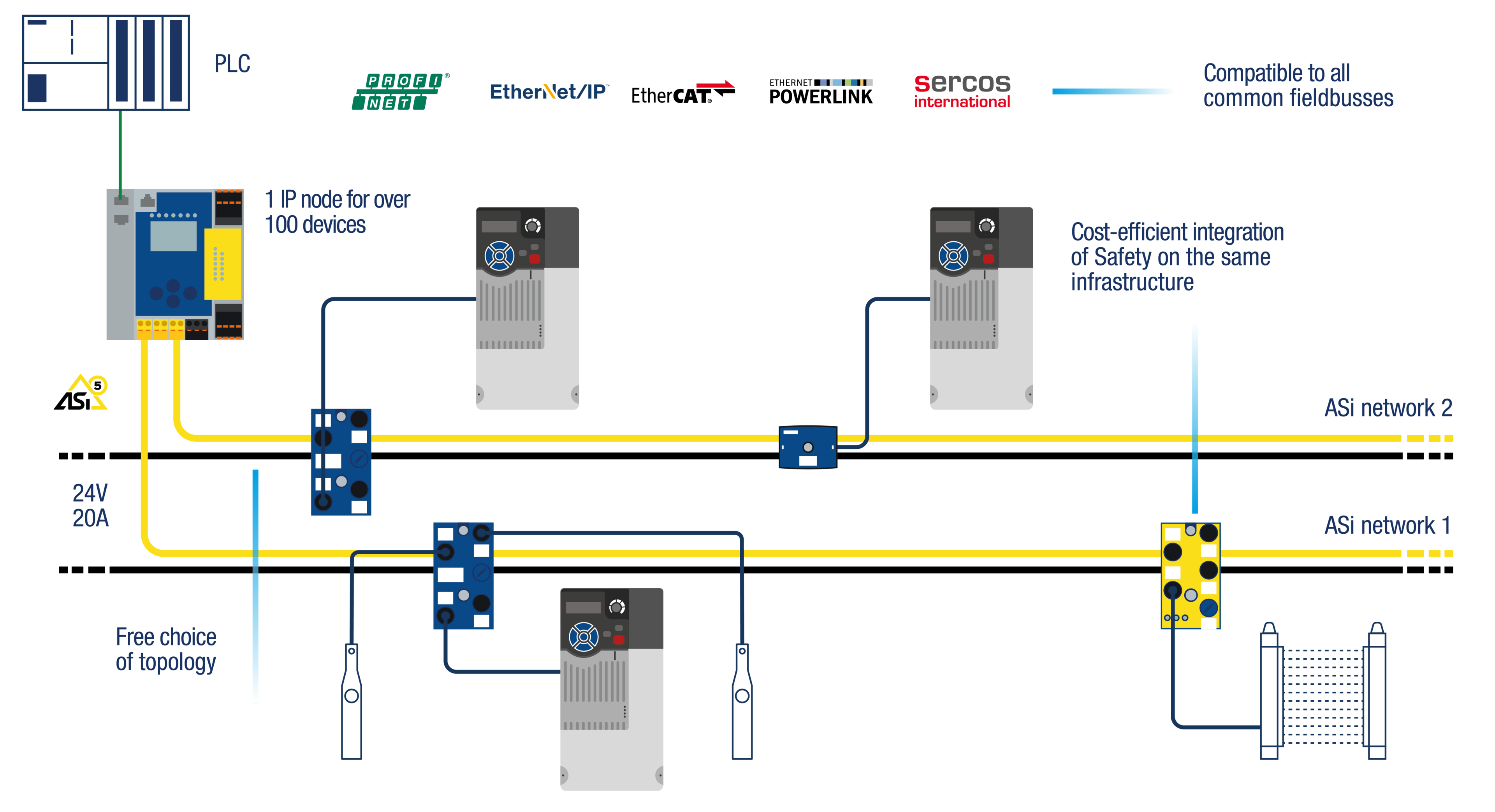

On this page, we present our ASi-5 drive solutions for Rockwell. The main advantages are: extremely simple wiring thanks to piercing technology, great freedom in the choice of topology as well as the transmission of standard and safety signals on the same cable. Both modules (BWU4369 and BWU4104) are suitable as a plug-and-play solution for connecting the Rockwell frequency inverter PowerFlex 525 / PF525.

Please contact us if the drive you are looking for is not listed here. Here you will find detailed information about the advantages of our AS-Interface drive solutions.

ASi-5 Module for Rockwell frequency inverter

With the ASi-5 Motor Module for the PowerFlex 525 frequency inverter (BWU4369), ramps and speed for process control can be changed cyclically thanks to ASi-5 and thus adapted extremely quick. An optimized process data image is available for this purpose. The feedback from the motor is also very comprehensive thanks to ASi-5. In addition to the error flags, the cyclical input data also includes, for example, the current consumption of the motor for evaluation.

Fig. The ASi-5 Motor Module for the Rockwell PowerFlex 525 frequency inverter (BWU4369) can be commissioned quickly via plug-and-play.

Active Distributor ASi-5 for Rockwell frequency inverter

With the ASi-5 Active Distributor (BWU4104), you can control the PowerFlex 525 frequency inverter efficiently. ASi-5 makes it possible to change ramps and speed for process control cyclically and thus adapt them very quickly. An optimized process data image is available for this purpose. You also benefit from the ability to easily create passive safety up to PLd/SIL2. The PowerFlex 525 can be safely switched off via Safe-Torque-Off (STO). By switching off the AUX auxiliary power, all connected or individual actuators are no longer supplied with auxiliary power. This allows individual or multiple drives to be switched off safely and cost-effectively.

The wiring costs are also significantly lower with ASi than with other fieldbus systems – thanks to profile cables and piercing technology. Further advantages of passive safety with Bihl+Wiedemann: The sensors can always be read out in the event of a safety incident. Communication with the frequency inverter is also continued in order to continue receiving diagnostic information.

Save time and costs, avoid parameterization errors

With the ASi-5 Motor Module BWU4369 and the Active Distributor ASi-5 BWU4104, you will, of course, benefit from the classic ASi advantages, e.g., drastically reduced wiring effort. A further advantage results from the use of our Bihl+Wiedemann Software Suite: Once you have configured an ASi-5 motor module and stored the Rockwell parameters, you can simply copy this information to numerous other ASi-5 motor modules. All motor parameters are automatically downloaded during commissioning. Parameterization is also automatic when motors and motor modules are replaced. This saves a lot of time and costs and also avoids possible parameterization errors.

Your advantages at a glance

One Rockwell frequency inverter can be controlled per module

Detailed diagnostics incl. motor current

Cyclical writing of speeds and ramps in 1.27 ms

Acyclic writing of Rockwell parameters

Save valuable resources

With AS-Interface, you do not need expensive plugs or sockets and only a single cable. This significantly reduces assembly times and material costs. In addition, valuable resources such as copper or plastic, which are required to manufacture the components, can be saved on a large scale. And energy consumption during cable production is greatly reduced. There is also a positive environmental effect when it comes to disposal – less waste is produced.

Solutions for drives from leading manufacturers

Bihl+Wiedemann offers a wide range of solutions for drives from many leading manufacturers – for motorized rollers (Interroll, Itoh Denki, RULMECA), DC motors (ebm-papst), and frequency inverters (SEW, NORD, Danfoss, Rockwell, Lenze, Bonfiglioli). Other manufacturers can also be integrated if necessary.