ASi-5 in Practice

ASi-5 reduces machine costs, paves the way for IIoT, is ideal for demanding drive technology applications and introduces you to many new options thanks to its high data bandwidth and short cycle times. Here you can read a few of the many success stories involving the resource-saving bus system with the simplest connection technology.

SAFELOG GmbH uses ASi-5 to optimize its intuitive picking solutions, which are used at Mercedes-Benz and other companies. For example, ASi-5 devices enable the implementation of pick-by-light technology, which minimizes picking errors and increases picking performance. ASi-5 also needs nothing more than a two-wire profile cable to connect the control unit and touchscreen to as many as 96 receiver devices.

Source: ASiMAG Edition 2022-E2

The drive technology manufacturer SEW-EURODRIVE is extending the application areas of its MOVI-C® modular automation system with ASi-5. ASi-5 has made it possible to significantly increase performance – while retaining the ingenious connection technology of AS-Interface. By combining ASi-5 and ASi-3 drive solutions, SEW-EURODRIVE can satisfy the respective requirements to perfection.

Source: ASiMAG Edition 2022-E1

Like most, the process industry is under intense cost pressure. For years, AS-Interface has been succeeding in reducing installation costs. The introduction of ASi-5 technology provided additional features to increase plant performance significantly. The strategic business units are pharma, food and biotech, industry, semiconductors, and medical.

Source: ASiMAG Edition 2023-E2

To make the machines in production Industry 4.0-capable, the screw manufacturer SPAX International relies on ASi-5/ASi-3 PROFINET gateways with safety monitor and compact IO-Link masters. The machines can be easily converted and now also enable predictive maintenance. In addition to digital information, IO-Link devices can now also provide process and diagnostic values.

Klinkhammer Intralogistics relies on safety solutions from Bihl+Wiedemann for the new storage and retrieval crane (SRC) of an automated high-bay warehouse. ASi-5 Safety gateways connected via Safe Link enable safe communication between the moving SRC and the control cabinet. Accelerating and decelerating the SRC as quickly as possible maximizes the throughput of goods.

RIELEC, based in Valencia, specializes in cost-efficient intralogistics solutions. The company relies on ASi-5 and ASi Safety for a new parcel sorter that sorts 1,800 cartons per hour for onward transportation to the right vehicle. ASi-5 reduces commissioning costs, enables expandable machine designs during the engineering phase and makes manufacturing processes faster and more flexible.

Success Stories From the Field

Discover success stories from the field, which we have realized together with our customers. Find out which industries and companies rely on innovative Bihl+Wiedemann applications.

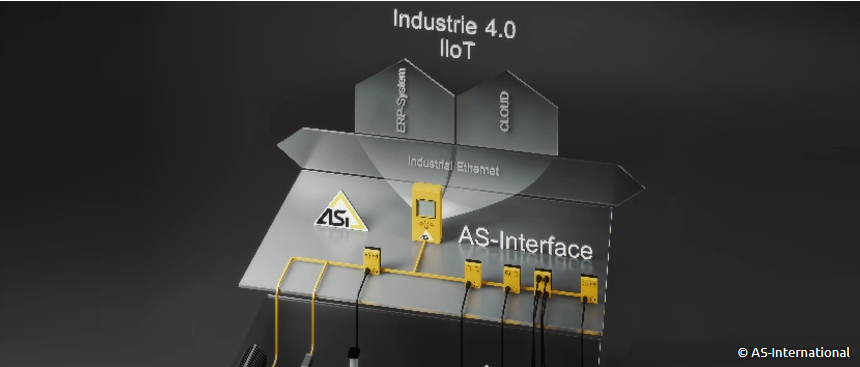

With a 52% increase in installed AS-Interface masters, which relates to a significant rise in AS-Interface networks when comparing the first half of 2022 to the first half of 2023, AS-International underlines its continuing growth and stands out economically and technologically.

Source: ASiMAG - Edition 2023 - E2

A group of development partners – consisting of automation technology providers Bihl+Wiedemann, Pepperl+Fuchs, Phoenix Contact, Siemens and chip manufacturer Renesas – have been working on a completely new generation of ASi since 2013. The work on ASi-5 was largely completed with the presentation at SPS IPC Drives 2018.