Functional safety – scalable solution, simple installation, less resources required

Comfortable, cost-effective, fieldbus-independent

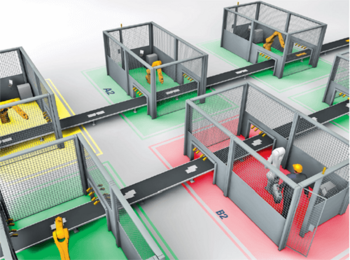

You want to implement or redesign functional safety easily? Without complex parallel wiring? And without expensive Ethernet-based solutions in the field? Discover a cost-effective and fieldbus-independent alternative with the simplest connection technology: We offer safety solutions for any plant size - from individual programmable safety relays to huge installations with up to 1922 safe signals. Our broad safety portfolio also includes proven solutions for various special applications such as Muting, Selection of Mode of Safe Operation or Speed Monitoring.

Our safety solutions require only a profiled two-wire cable. Thanks to piercing technology, installation is foolproof: modules can simply be plugged onto the reverse polarity protected profile cable - exactly where they are needed. The modules can not only be supplied via the two-wire line, but all safe and standard signals are also transmitted via it. This eliminates the need for costly duplicate infrastructure. Our ASIMON360 PC software enables convenient parameterization of the safety technology.

Content

- Comfortable, cost-effective, fieldbus-independent

- Save valuable resources

- Safety solutions with Bihl+Wiedemann

- Safe small control

- Safety technology with fieldbus interface

- Our safety components at a glance

- Pre-finished solutions for many use cases

- Cost-effective scalability through Safe Link

- Functional safety - advantages at a glance

Scalable solution

Our portfolio offers the right solution for every plant size: for applications with few configurable safety relays, our Safety Basic Monitor BWU2700 with 4 safe inputs and 2 safe electronic outputs, is a modern and comfortably programmable alternative. This can be extended by further 31 safe signals if required. For very large installations with up to 1922 safe signals, you can connect up to 31 of our Safety Gateways via Safe Link.

Many use cases

We offer advanced safety solutions for a wide range of complex applications. Discover our range of solutions for muting, analog value processing, speed monitoring, safe operation mode selection, control-independent safety technology as well as our active distributors. The latter are plug-and-play modules that are adapted, for example, to many safety switches with integrated AS-Interface from various manufacturers.

Simplest connection technology

Thanks to the ASi piercing technology, modules can be connected, exchanged, relocated or added very easily - with maximum safe contacting. The special profile of the ASi cable prevents nodes from being connected with reversed polarity - and all this with complete topology freedom. In addition, ASi wiring is usually considerably less expensive than round cable solutions with typical M12 or 7/8" connectors. The cost savings can be as much as 68 %.

Detailed diagnostics

The diagnostic software included in the software suite enables release measurements, provides detailed diagnostics and gives concrete recommendations for action in the event of errors. The most important diagnostics are also immediately visible in the plant without any additional software, because a corresponding display is integrated in the gateways.

Save valuable resources

With AS-Interface, you do not need expensive plugs or sockets and only a single cable. This significantly reduces assembly times and material costs. In addition, valuable resources such as copper or plastic, which are required to manufacture the components, can be saved on a large scale. And energy consumption during cable production is greatly reduced. There is also a positive environmental effect when it comes to disposal – less waste is produced.

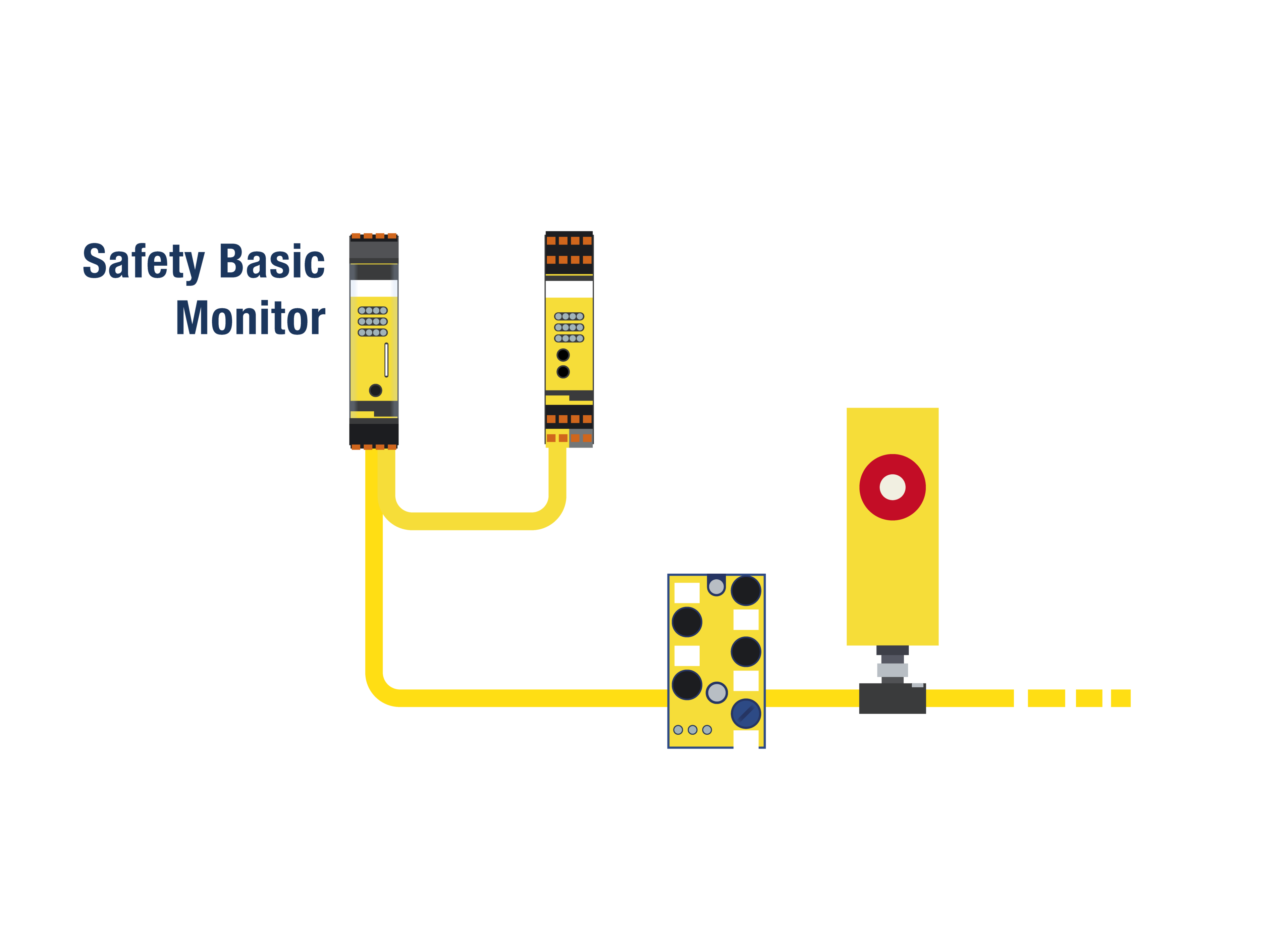

Safe small control

The Safety Basic Monitor

For small applications with three or more safe signals, we offer the Safety Basic Monitor, a safe small control without gateway, but with configurable signal outputs. The ASi Safety Module is universally expandable and is also suitable as a head station for special safety applications.

- Cost-effective variant for small applications

- Safe small control

- Large range of functions

- Easily expandable via ASi

- Easy to integrate into existing systems

- Simple coupling to other systems

- Programmable via PC

- Max. 31 safe modules per device

- Width of Safety Basic Monitor: 22.5 mm

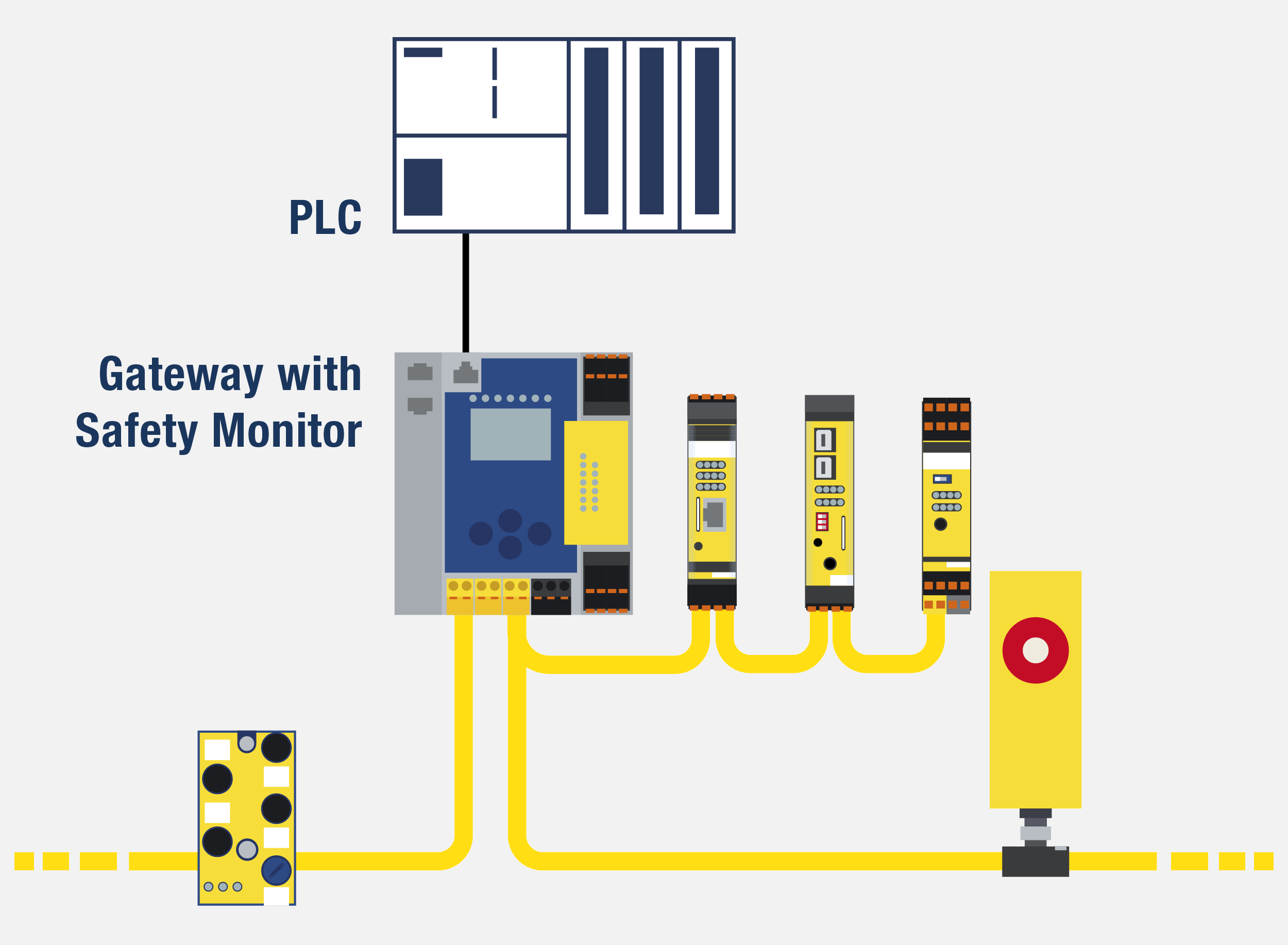

Safety technology with fieldbus interface

Gateways with integrated safety monitor

Our ASi Gateways can transmit digital and analog sensor data, which are read in decentrally via ASi modules, to the higher-level control via the respective bus system. The ASi Gateways also transmit the output signals of the control to the ASi actuators. The integrated Safety Monitor implements the safe transmission and evaluation of safety-relevant diagnostic data from safe input modules - as well as the safe switch-off of safe output modules decentrally via ASi wherever the potentially dangerous movement occurs. And that with up to SIL3/PLe.

- Optimal PLC connection via the common fieldbuses

- Safety and standard signals via the same infrastructure

- Standard signals and all diagnostic data in the control

- Max. 62 safe modules/devices

- Optionally with safe fieldbus protocol (PROFIsafe, CIP Safety, FSoE, ...) for exchanging safe data with a safe control

- Expandable via Safe Link

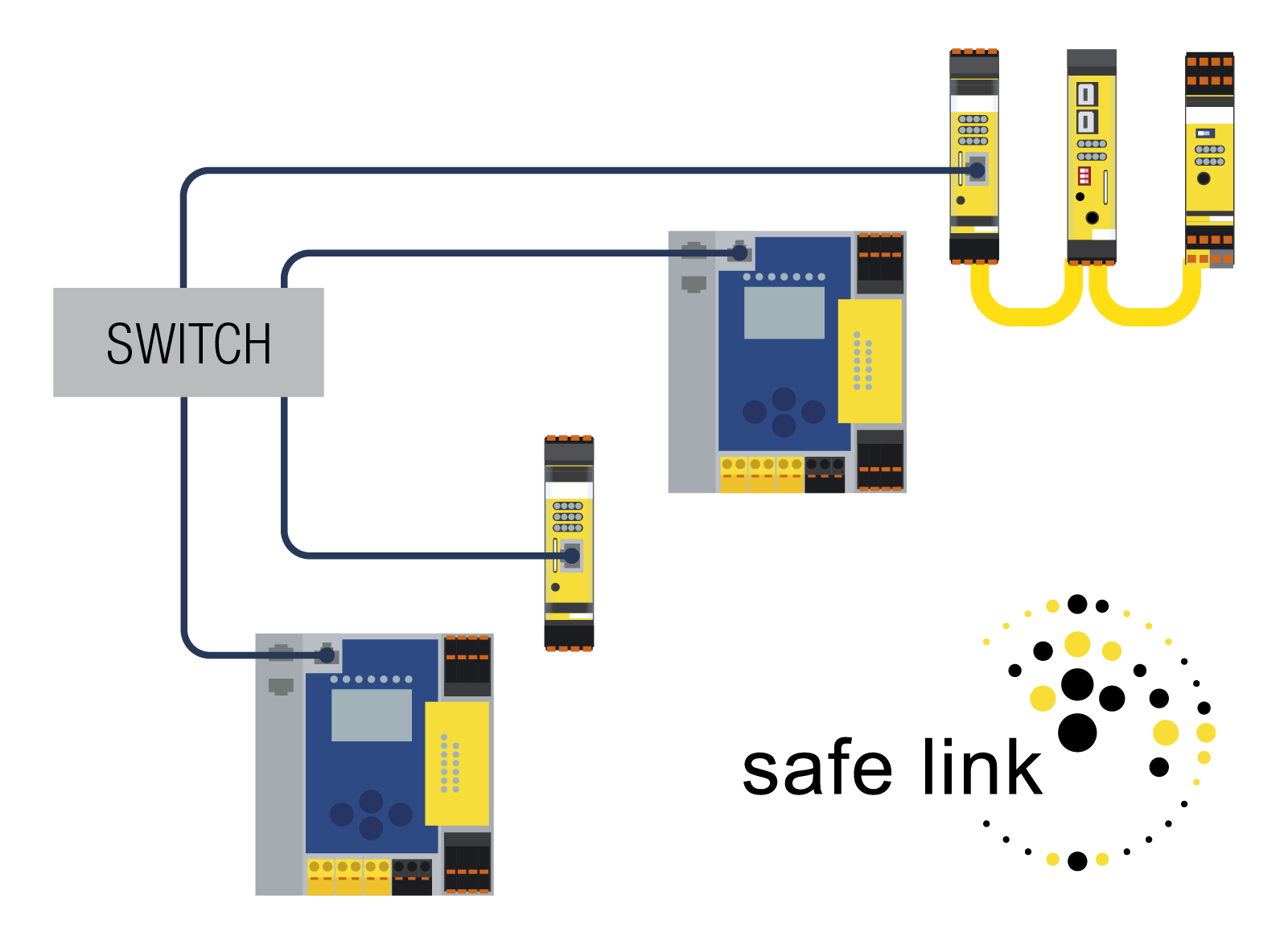

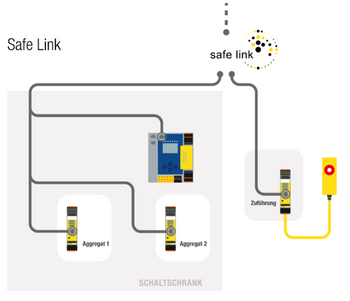

Cost-effective scalability through Safe Link

Safe coupling via Ethernet

The latest gateways and Safety Basic Monitors with Ethernet interface already have our technology for safe cross communication - Safe Link - integrated. This allows multiple devices to be implemented into very large installations with up to 1922 safe signals at no additional cost. In this way, several plant sections can be easily and flexibly connected with each other - even if different controls are used. Safe Link means that our safety monitors communicate safely with each other. Either via the Ethernet-based fieldbus interface, for example PROFINET or EtherNet/IP, or via the Ethernet diagnostic interface. Safe Link simply communicates additionally via the respective Ethernet connection and at the same time fulfills the safety requirements of SIL3.

- Safe coupling of Safe Link via Ethernet

- Max. 31 devices with up to 62 safe modules per device

- 31 safety bits per monitor

- Everyone hears everyone

- Simplest way to safely couple many signals

Selection of Mode of Safe Operation

Today, for complex machines it is often necessary to allow several safe operating modes, e.g. setup mode with the safety door open and at reduced speed. Via a standard HMI, up to 5 different operating modes can be safely selected for a maximum of 6 plant sections - each with individual safety functions. Configuration of the operating modes is very simple thanks to the ASIMON360 software. With the Euchner EKS electronic key system, access can be restricted to authorized groups of people.

Passive safety up to SIL3/PLe

The yellow ASi profile cable and the optional black profile cable for auxiliary power (for energy-intensive peripherals such as roller drives) can easily be routed separately - even in the modules. Connected actuators supplied out of AUX are therefore safely switched off when the auxiliary power is switched off. The safety-related disconnection of actuator groups can be implemented cost-effectively with only one safe output.

Safe Link

With Safe Link, different parts of the plant can be connected to each other easily and flexibly - even if different controls are used. Up to 31 Safety Basic Monitors or gateways with integrated safety monitor can be coupled with each other. In this way, up to 1922 safe two-channel input signals can be collected.

Speed monitoring

We offer many solutions for safe speed and position monitoring: from speed monitoring at the local terminals of the gateways and Safety Basic Monitors by means of simple initiators, to powerful modules for HTL and TTL encoders. In addition to speed and standstill, important details such as direction of rotation, shaft break, slippage or a position range can also be monitored.

Safety Monitor

The Safety Monitor enables safe transmission and processing of safety-relevant data from safety input modules and safe shut-off of safety output modulesremotely over ASi right where the potentially hazardous motion takes place. The Safety Monitor is always PLe compliant. Bihl+Wiedemann offers the Safety Monitor for ASi Safety at Work as a stand-alone device to expand existing ASi networks with safety modules. For new systems, we can provide ASi-3 resp. ASi-5/ASi-3 Gateways with integrated Safety Monitor and interfaces for the most commonly used automation systems. This presents the most efficient method for safely constructing one or two ASi networks at the same time. Employing our "Safe Link" over Ethernet, a technology to connect multiple Gateways safely over Ethernet/Profinet, even large applications with up to 1922 safety I/Os can be implemented. For small applications with three or more safe signals, you should consider the Safety Basic Monitor, a compact safety controller without gateway but with configurable status outputs, the module allows for universal expansion and is the ideal control station for special safety applications.

Safety I/O Modules

Bihl+Wiedemann offers the right module to collect and process any safety input signal. Both enclosure-mount (IP20) and field-mount(IP67) modules are available. From a single safety input or output to safety multi-I/O modules we offer the right ASi module for your requirementes. Many of our modules also include conventional outputs for non-safe signals.

Active Distributors ASi Safety

Active distributors ASi Safety from Bihl+Wiedemann allow you to make any safety sensor, safety push-button or switch AS-Interface capable. Even modules without their own ASi terminal can be easily integrated into an existing ASi network using these active distributors ASi Safety. Other features include individually configurable connection options using M8 or M12 connectors, flying leads or push-in terminals to conform to the customer’s application, as well as a compact form factor, making them ideal for use in cable ducts.

E-STOP

Bihl+Wiedemann offers a range of control and signal devices based on an innovative enclosure. The E-STOP switch module features a safety ASi input module and is available with 2-colour illumination – either depending on the actuator position or as specified by the controller. The E-STOP is designed for extruded rail mount (40mm), but can also be individually attached using a mounting clip. The ASi connection is made conveniently using an M12 connection. Bihl+Wiedemann also offers various other control and signal devices in the same enclosure.