IO-Link with Bihl+Wiedemann: easy, flexible & cost-efficient

Warum sollten Sie IO-Link mit uns integrieren?

IO-Link Devices sind in Maschinen und Anlagen heutzutage allgegenwärtig. Denn mit IO-Link lassen sich Sensoren und Aktuatoren über eine kostengünstige Punkt-zu-Punkt-Verbindung an die Steuerungsebene anbinden. Mehr über IO-Link und die damit verbundenen Vorteile erfahren Sie hier.

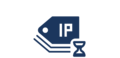

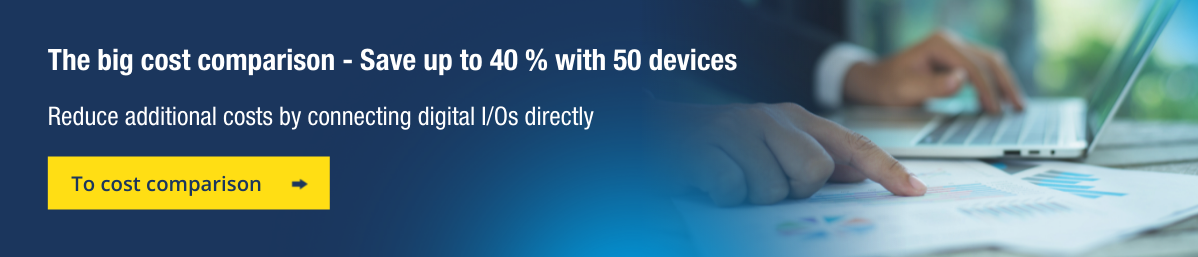

Auf dieser Seite geht es vor allem um folgende Frage: Was ist der beste Weg für die Integration von IO-Link? Bihl+Wiedemann bietet Ihnen hierfür ein ausgereiftes Konzept: IO-Link ist dazu perfekt in ASi-5 und unsere benutzerfreundliche PC-Software eingebettet– vom Device bis zur SPS bzw. Cloud. Mit unserer feldbusunabhängigen Lösung profitieren Sie nicht nur von der Freiheit in der Topologiewahl, einem reduzierten Verdrahtungsaufwand ohne Switches und einem smarten Energieversorgungskonzept. Weitere Vorteile sind geringer IP-Verwaltungsaufwand sowie preiswerte IO-Link Master, die wir mit 1, 2, 4 und 8 Ports anbieten. Zahlreiche technische Features ermöglichen Ihnen zudem eine maximal komfortable Inbetriebnahme von IO-Link Devices. Für uns steht fest: Cleverer und wirtschaftlicher können Sie IO-Link nicht integrieren.

Content

- Warum sollten Sie IO-Link mit uns integrieren?

- Instead of Connecting IO Hubs to IO-Link Masters, use our IO Modules Directly

- Advantages at a glance

- IO-Link Safety Solutions from Bihl+Wiedemann

- FAQ about IO-Link

- IO-Link products

- IO-Link with Bihl+Wiedemann

- Instead of connecting IO hubs to IO-Link masters, use our IO modules directly

Advantages at a glance

Einfachste

Inbetriebnahme

Über unser komfortables Konfigurationstool lassen sich IO-Link Master leicht einbinden. Sie können z. B. die IODD einfach aufrufen und werden bei der Parametrierung von IO-Link Devices grafisch unterstützt. Die Live-Parametrierung der Devices ermöglicht eine direkte Kontrolle der vorgenommenen Einstellungen.

Automatische Parametrierung beim Gerätetausch

Bei der Mehrfachverwendung eines Setups können die Parameter der angeschlossenen IO-Link Devices dank unserer PC-Software einfach von Master zu Master kopiert werden. Dies gilt sowohl innerhalb von Projekten als auch projektübergreifend. Die Kopierfunktion spart besonders beim Einsatz vieler IO-Link Devices sehr viel Zeit und reduziert Parametrierfehler.

Integrierter

OPC UA Server

Unsere ASi-5/ASi-3 Gateways besitzen alle einen integrierten OPC UA Server. Dieser ermöglicht es Ihnen, die Prozess-, Parameter- und Diagnosedaten der IO-Link Devices einfach und kostengünstig in die Cloud oder HMI zu übermitteln – eine Voraussetzung für moderne Anlagen in Zeiten von Industrie 4.0.

Smart

Wiring Concept

The amount of effort required for wiring is reduced because all nodes – IO-Link devices, standard sensors and safety modules – are connected to an unshielded 2-core cable using piercing technology. Besides, the maximum IO-Link cable length of 20 meters plays a secondary role in our case because you can distribute the IO-Link masters anywhere on the AS-Interface cable with up to 200 meters in length.

Smart

Energy Distribution

In round cable solutions, the respective connector indirectly determines the "limit" for individual IO-Link masters and for the total current of all IO-Link masters connected in series. With ASi, no loop-through from module to module is needed . The AUX supply is done over reverse polarity protected profile cables, so each IO-Link master draws its energy individually – at 20 A per AUX cable.

Full

Flexibility

While common IO-Link masters are only available from 4 ports or more, ASi also offers the possibility to efficiently integrate 1- or 2-port IO-Link masters. This means that even distributed individual IO-Link devices can be perfectly integrated. You also enjoy great freedom in the choice of topology

and can implement a star, ring, line and network structure, for example. You also gain maximum flexibility through the fieldbus independence of our IO-Link masters.

Reduced

Overall Costs

Our IO-Link masters with 4 ports are, for instance, about 50 % cheaper than comparable modules from other manufacturers. This means that the costs for our gateway are recovered, for example, from just 3 IO-Link masters with 4 ports each. You also reduce your installation workload and benefit from the elimination of switches and pre-assembled cables. Click here to view our main cost comparison.

The IO-Link master is integrated as an ASi node into the ASi network

IO-Link devices can be integrated into the ASi network along with standard sensors, standard actuators and safety components

All process data (up to 32 bytes per port) of the IO-Link devices is available via the cyclic ASi communication.

All IO-Link parameters can be conveniently adjusted through the B+W Software Suite or acyclically via the control system

Diagnostic information from IO-Link available via ASi

Our IO-Link masters can be optimally combined with IO-Link devices from any manufacturer

If an IO-Link device needs to be replaced, its parameters are stored in the IO-Link master and are transferred automatically to the new one.

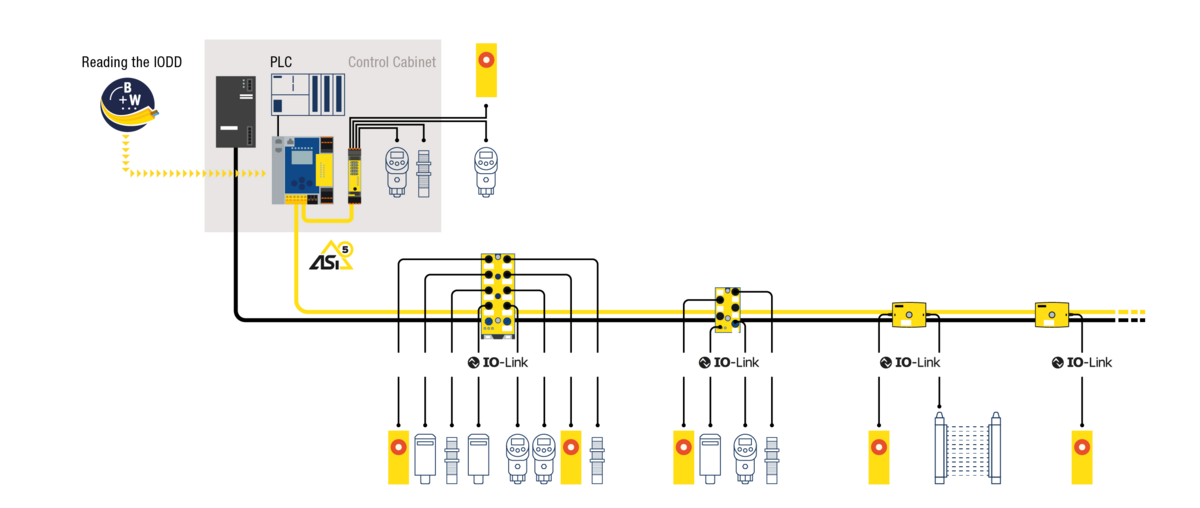

IO-Link Safety Solutions from Bihl+Wiedemann

IO-Link Safety is an extension of IO-Link. There is an additional safety communication layer on the master and device side. These become the "Fail-Safe (FS) master" and "Fail-Safe (FS) device". Bihl+Wiedemann is in the process of developing its own "FS master". IO-Link is already a perfect match for the safety components of Bihl+Wiedemann.

Reduced machine-related costs

A cost-efficient standard cable establishes a connection up to 20 meters long between the IO-Link master and IO-Link device.

High machine availability

Downtimes are reduced because when a defective IO-Link device is replaced, its parameters are automatically transferred to the new sensor by the IO-Link master or control system.

Efficient operation

IO-Link devices can be positioned in the machine directly at the work site. These do not have to be accessible for parameterization.

Demand-oriented maintenance

Continuous diagnostic data of the entire process lengthen maintenance intervals, since systems and machines need to be maintained much less frequently due to the automatic readjustment via IO-Link

It is possible to extend existing bus systems. As a prerequisite, the system mapping of IO-Link for the respective bus system must be already implemented. It is particularly easy to use IO-Link in conjunction with the ASi intelligent wiring system. Thanks to piercing technology, corresponding IO-Link masters can be easily retrofitted where they are needed.