Bihl+Wiedemann ile IO-Link: kolay, esnek, ucuz

IO-Link nedir?

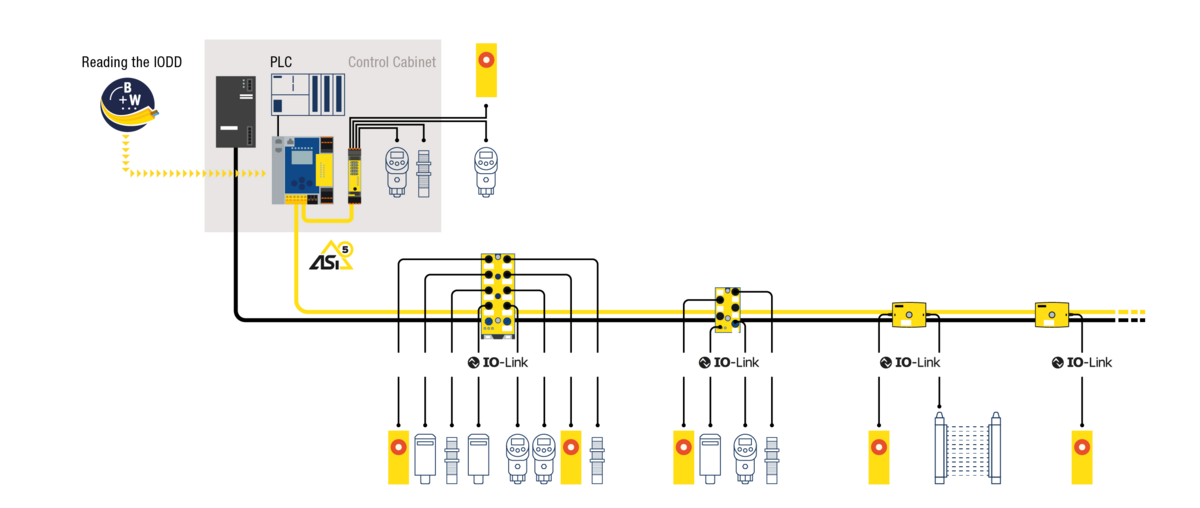

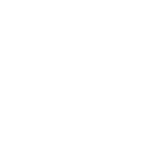

IO-Link saha seviyesindeki “son metreye kadar” kesintisiz iletişim sağlayan bağımsız bir fieldbus arayüzüdür. IO-Link ile sensörler ve çalıştırıcılar kontrol sistem seviyesine bağlanılabilir. Bu bağlantı, düşük maliyetli, korumasız üç damarlı kablo üzerinden standart bir şekilde noktadan noktaya gerçekleşmektedir. Açık bir arayüz ile IO-Link tüm ortak fieldbus ile otomasyon sistemlerine entegre edilebilir.

Uluslararası IO-Link standardı (IEC 61131-9), merkezi arıza teşhisini ve aktüatör/sensöre kadar lokalizasyonunu mümkün kılar. Proses değerlerine ek olarak parametre veya teşhis mesajları gibi daha fazla bilgi değişimi gerçekleşmektedir. IO-Link aynı zamanda çalışma sırasında kontrol sistemi üzerinden ilgili üretim gereksinimlerine uyarlanabilmektedir.

The IO-Link master is integrated as an ASi node into the ASi network

IO-Link devices can be integrated into the ASi network along with standard sensors, standard actuators and safety components

All process data (up to 32 bytes per port) of the IO-Link devices is available via the cyclic ASi communication.

All IO-Link parameters can be conveniently adjusted through the B+W Software Suite or acyclically via the control system

Diagnostic information from IO-Link available via ASi

Our IO-Link masters can be optimally combined with IO-Link devices from any manufacturer

If an IO-Link device needs to be replaced, its parameters are stored in the IO-Link master and are transferred automatically to the new one.

Instead of connecting IO hubs to IO-Link masters, use our IO modules directly

In order to collect many digital I/Os, IO hubs and IO-Link master ports are often used - there is great potential for optimization here. Simply use an ASi-5 self-configuring I/O module from Bihl+Wiedemann: The 16 digital signals of the BWU4230 can be used as inputs or outputs in any desired way - and can be integrated without the detour via IO-Link. By simply integrating digital I/Os via ASi, you do not need any additional IO-Link masters and also transmit the standard signals significantly faster. At the same time, there is no need for M12 connection cables between IO-Link I/O hubs and IO-Link master ports.

The maximum IO-Link cable length of 20 meters is also irrelevant. Find out here why this is the case.

ASi-5 Slave / 4 portlu IO-Link Master, IP20

Bihl+Wiedemann yazılım paketleri ile uygun parametre ataması

- 1,27 ms proses data içerisinde 4 x 16 Bit’e kadar aktarım

- 32 bayta kadar döngüsel işlem verisi

4 IO-Link portu (BWU3843)

Aktif Distribütör

ASi-5 / IO-Link Master

- Bihl+Wiedemann yazılım paketleri ile uygun parametre ataması

- 1,27 ms proses data içerisinde 4 x 16 Bit’e kadar aktarım

- 32 bayta kadar döngüsel işlem verisi

- 2 IO-Link portu, örn.: 1 IO-Link portu A-Sınıfı, 1 IO-Link portu B-Sınıfı (BWU4077)

ASi-5 Module with integrated IO-Link Master with 8 Ports, IP67

- 8 × IO-Link Ports Class A in one housing (BWU4386)

- Additional I/O Signal on pin 2

Bihl+Wiedemann’dan IO-Link Safety Çözümleri

IO-Link Safety IO-Link’in bir uzantısıdır. Master ve cihaz tarafında ek olarak bir emniyet iletişim katmanı mevcuttur. Bunlar ‘’Fail-Safe (FS) [Tedbirli] master’’ ve ‘’Fail-Safe (FS) [Tedbirli] cihazı’’ olarak tanımlanmıştır. Bihl+Wiedemann kendi ‘’FS masterini’’ geliştirme sürecindedir. Bihl+Wiedemann’ın emniyet bileşenleri için IO-Link henüz mükemmel bir eşleşmedir.

Düşük maliyetli makine giderleri

Düşük maliyetli bir standart kablo 20 metreye kadar IO-Link ile master ve IO-Link cihazı arasında bağlantı kurmakta.

Yüksek makine kullanılabilirliği

Hatalı bir IO-Link cihazın değişiminde cihazın parametresi IO-Link master veya kontrol sistemi tarafından otomatik olarak yeni sensöre yazıldığı için kesinti süreleri azalmaktadır.

Etkili kullanım

IO-Link cihazları makinenin içerisinde doğrudan iş yerine konumlanmaktadır. Parametreleme için bnlar erişebilir olmak zorunda değildir.

Talep odaklı bakım

Tesis ve makineler IO-Link ile otomatik yeniden ayarlama üzerinden daha az sıklıkla bakıma ihtiyaç duyduğu için tüm sürecin sürekli kesintisiz olan teşhis verileri bakım aralıklarını uzatır.

Mevcut olan bus sistemlerin genişletilmesi temelde mümkündür. Bunun için ön koşul, IO-Link sistematik şemasının ilgili bus sistemi için gerçekleştirilmiş olmasıdır. IO-Link’i akıllı kablolama sistemi ASi ile temas haline getirmek oldukça kolaydır. İğneleme teknolojisi sayesinde ilgili IO-Link master basitçe ihtiyaç duyulan yerde güçlendirilebilir.

![[Translate to Türkei (EN):] ASi-5 Datenbreite [Translate to Türkei (EN):] ASi-5 Datenbreite](/fileadmin/_processed_/8/f/csm_ASi-5-Icon-Autobahn_8daec96033.png)

![[Translate to Türkei (EN):] ASi-5 Zykluszeit [Translate to Türkei (EN):] ASi-5 Zykluszeit](/fileadmin/_processed_/b/c/csm_ASi-5-Icon-Stopuhr_6f0a6202b3.png)

![[Translate to Türkei (EN):] ASi-5 Kompatibilität [Translate to Türkei (EN):] ASi-5 Kompatibilität](/fileadmin/_processed_/b/d/csm_ASi-5-Icon-Puzzle_4b27479278.png)

![[Translate to Türkei (EN):] ASi-5 IO-Link Integration [Translate to Türkei (EN):] ASi-5 IO-Link Integration](/fileadmin/_processed_/7/1/csm_ASi-5-Icon-Birne_cccb01b93a.png)

![[Translate to Türkei (EN):] ASi-5/ASi-3 Gateways mit integriertem Sicherheitsmonitor [Translate to Türkei (EN):] ASi-5/ASi-3 Gateways mit integriertem Sicherheitsmonitor](/fileadmin/_processed_/b/0/csm_3674_d31359c0c2.png)

![[Translate to Türkei (EN):] ASi-5/ASi-3 Gateways in Edelstahl [Translate to Türkei (EN):] ASi-5/ASi-3 Gateways in Edelstahl](/fileadmin/_processed_/6/1/csm_3848_ebecc82698.png)