ASi Cable - simple and efficient power distribution

What Makes the ASi Cable so Special?

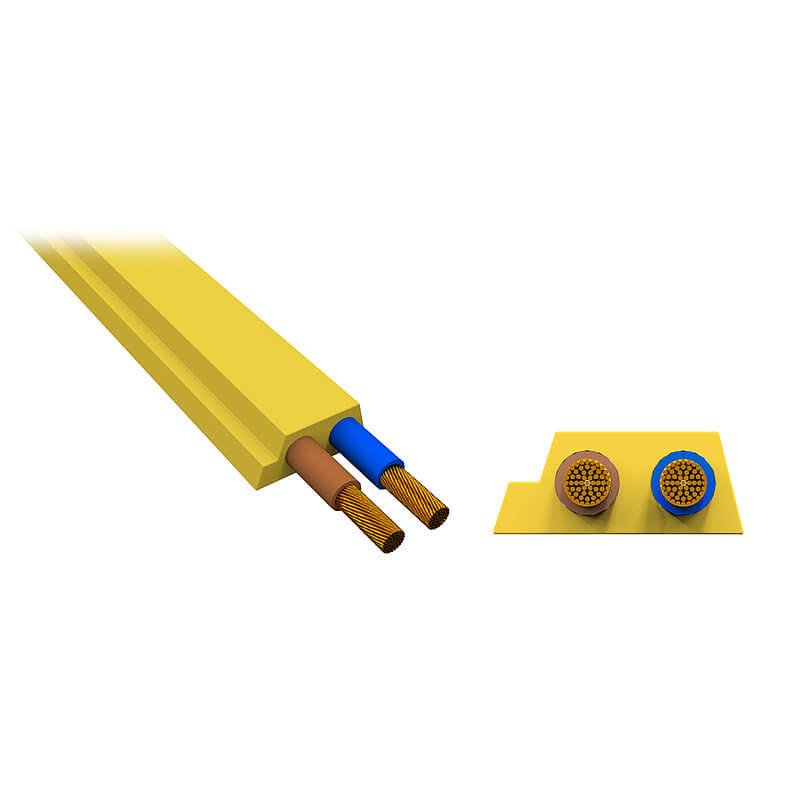

Cables are mostly round. This has always been the case and with good reason. Round cables are particularly easy to route, and the channels can be sealed without difficulty. So why is the cable of the supposedly simplest fieldbus system in the world flatand also has a mechanically coded profile? Because the typical yellow ASi cable is the key to the simplicity of AS-Interface. The unshielded, 2-core cable not only transmits data and power, it also enables easy and cost-effective installation of ASi or ASi-5 in the field.

Thanks to piercing technology, field devices can easily be installed on the mechanically coded (thus reverse polarity protected) ASi cable – with perfect contact and while still achieving protection class IP67. An additional 24 V supply is possible without problems. AS-Interface is therefore ideal for power-intensive applications such as IO-Link devices or motors in conveyor applications. And since power efficiency and higher electrical power are becoming increasingly important, we also offer modules for use with 48 V motors.

Content

- What Makes the ASi Cable so Special?

- ASi Cable – Advantages at a Glance

- Extremely Simple Installation, Perfect Contacting

- Efficient Power Supply up to 20 A

- Wiring Costs in Comparison

- Clear Separation of Control Signals from Auxiliary Power

- Combined Use of Profile Cables and Round Cables

- Profile Cables for Different Usage Scenarios

- FAQs About the ASi Cable

ASi Cable – advantages at a glance

Distribute a lot of power easily, save plenty of assembly time and reduce costs at the same time – with the ASi cable, you benefit in many ways.

Save valuable resources

With AS-Interface, you do not need expensive plugs or sockets and only a single cable. This significantly reduces assembly times and material costs. In addition, valuable resources such as copper or plastic, which are required to manufacture the components, can be saved on a large scale. And energy consumption during cable production is greatly reduced. There is also a positive environmental effect when it comes to disposal – less waste is produced.

Extremely simple installation, perfect contacting

Thanks toASi piercing technology, it is possible to connect, replace, move or add modules (e.g. ASi-5 modules or IO-Link masters with 1, 2, 4 or 8 ports) very easily. Benefits when using the ASi profile cable include the following:

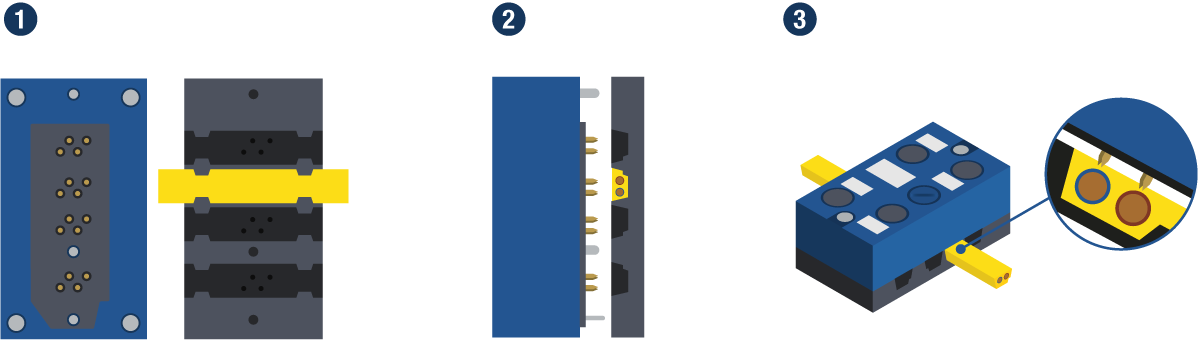

- Very simple connection technology: Modules pierce the insulation of the profile cable. At least four gold-plated needles pierce vertically and reliably through the rubber sheath into the cable, where the two cable wires come into contact.

- Maximum safe contacting: Two needles per wire penetrate the profile cable redundantly. Low contact resistance is also guaranteed.

- Reduced installation effort: There is no need for cutting or stripping and terminating the cable as with round cables. The profile cable is simply taken from the cable reel in the desired length.

- Zero Euro connection costs: Neither pre-assembled cables nor T-pieces are required to connect modules. This makes the retrofitting or conversion of systems unrivaled in terms of cost.

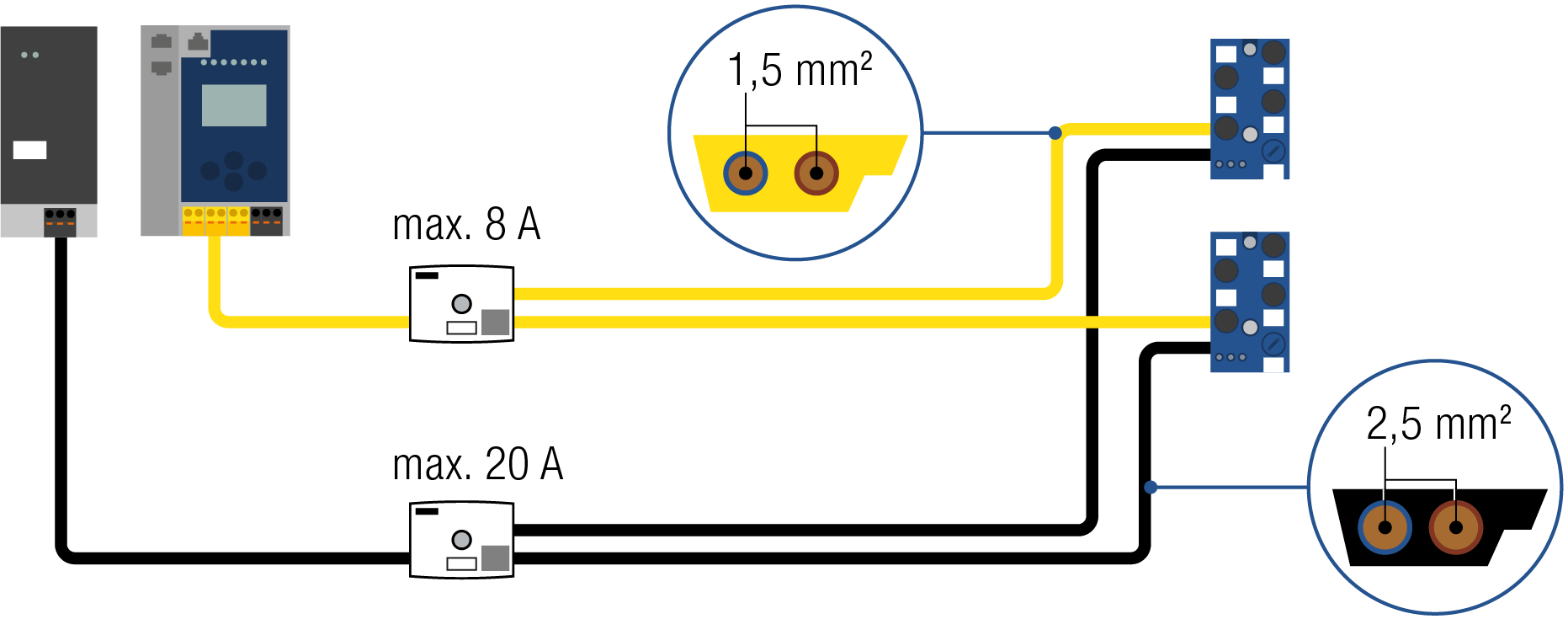

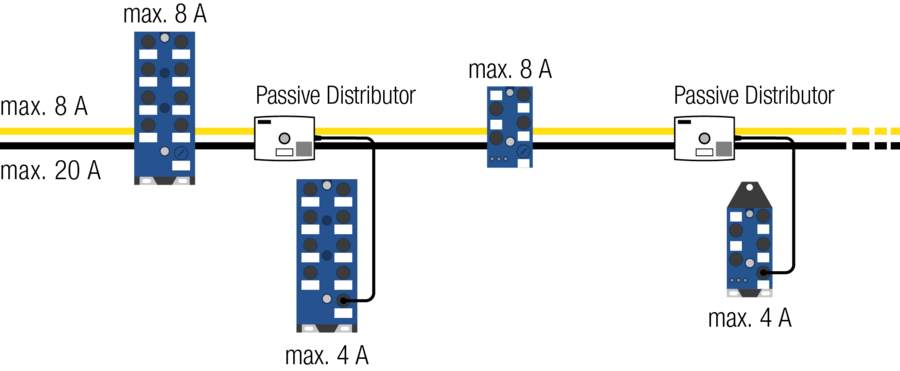

Efficient power supply up to 20 A

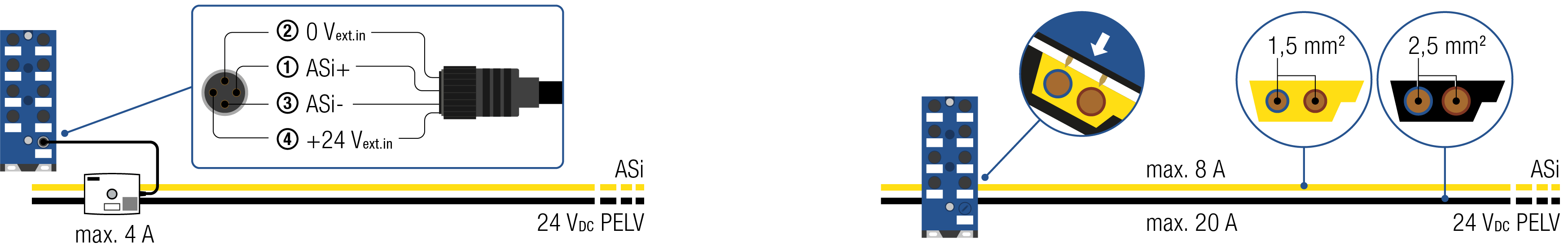

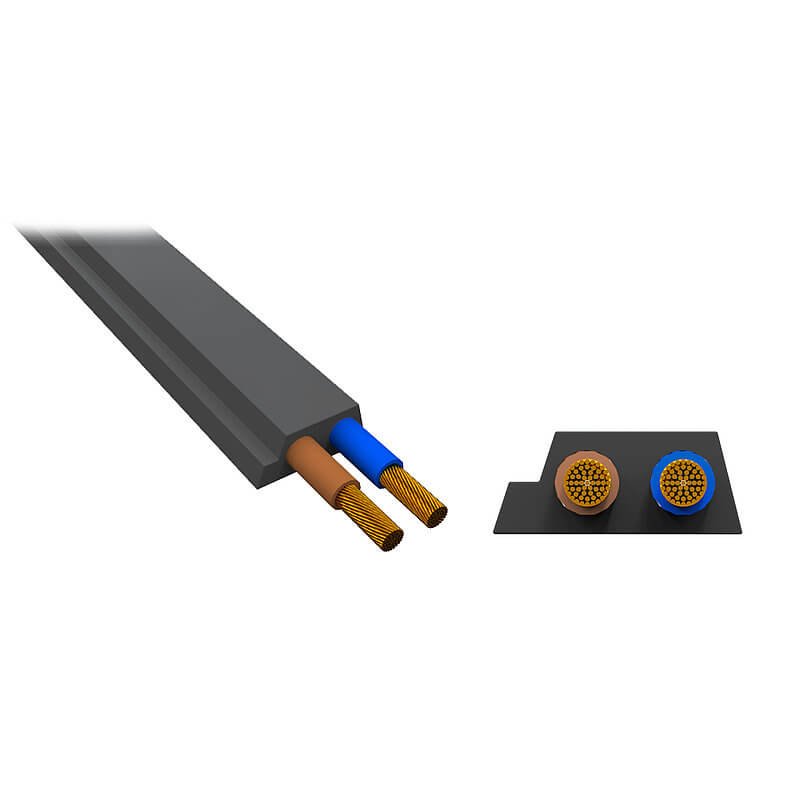

Efficient power distribution is a major challenge in many applications – and no less for IO-Link solutions and motors in conveyor applications. This is where the black profile cable is best suited, as it transmits up to 20 A. Compared to round cable solutions, the profile cable offers many advantages:

Significantly more power

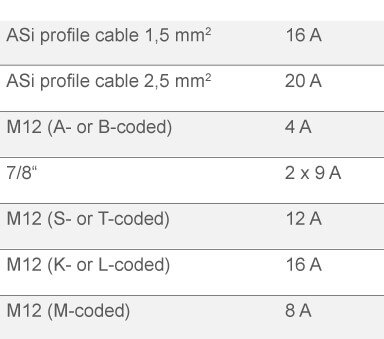

The black profile cable provides 16 A or 20 A depending on the cable cross-section. In contrast, round cables with typical M12 or 7/8" plugs are usually only designed for much lower currents (see table on the right).

No looping through

In round cable solutions, the respective plug indirectly determines the "limit" for individual modules and for the total current of all modules connected in series. That's because unlike ASi, the power in such configurations often needs to be looped through the modules, resulting in power losses.

Less costs

The profile cable can provide up to 16 A as standard. To transmit more than 4 A over an M12 connection, you need to use expensive connectors with special power coding. But even when an application only requires a low power supply, ASi solutions based on a profile cable almost always turn out to be more cost-effective.

Power supply for non-ASi participants

Special passive distributors allow a wide variety of non-ASi field devices to be connected to the profile cable and thus supplied with power. Bihl+Wiedemann offers a broad range of products in this area and can also develop tailor-made passive distributors on customer request.

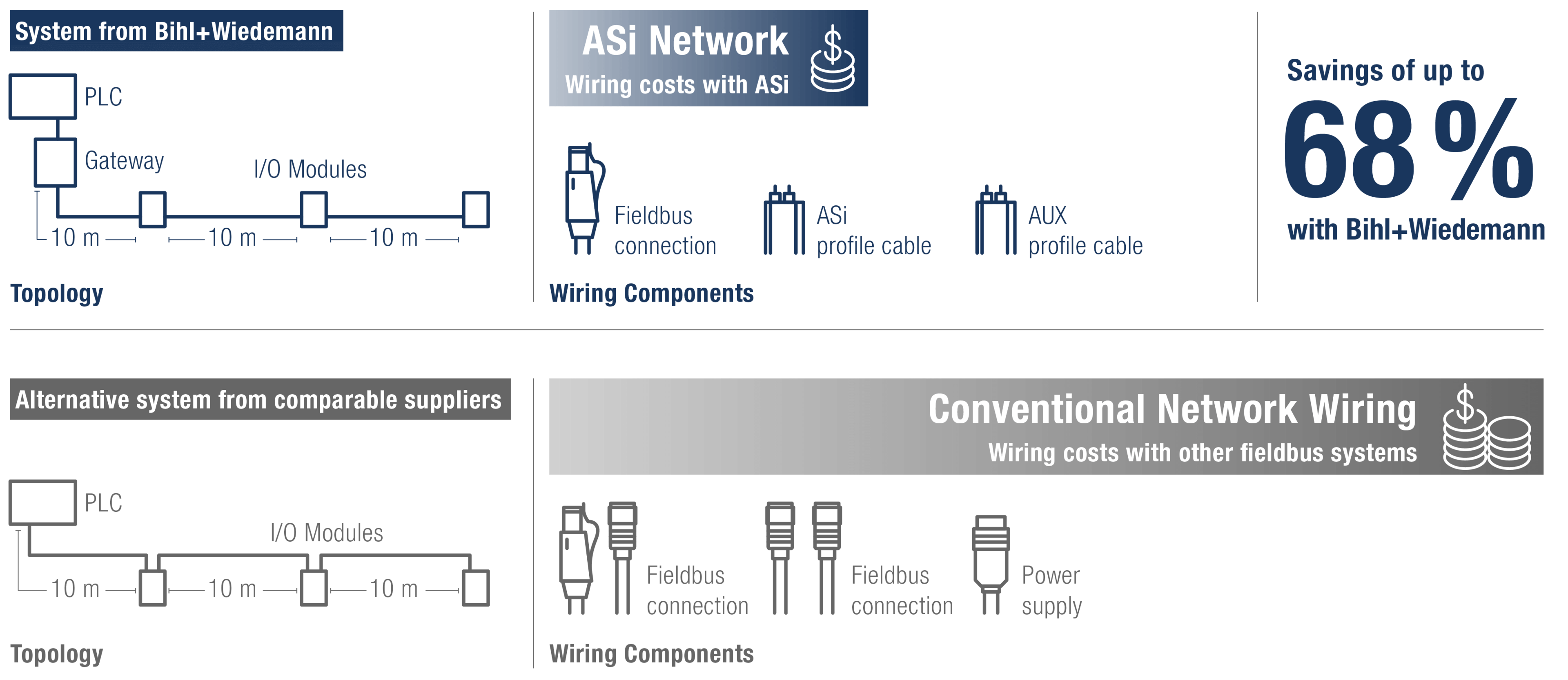

Wiring costs in comparison – ASi cable beats other fieldbus systems

Thanks to profile cables and piercing technology, ASi wiring couldn't be any more simple because you don't need different pre-assembled connection cables, so you spare plenty of costly assembly time. You do not need to know the length of the cables used beforehand because ASi gives you the flexibility to decide on site where you want to install the modules on the profile cable. This noticeably reduces the planning effort and achieves a further cost advantage.

Wiring costs with ASi are significantly lower than with other fieldbus systems. As shown in the calculation below, our product lets you save up to 68 percent. Last, but not least, with ASi solutions by Bihl+Wiedemann, your overall costs will also decrease in many cases.

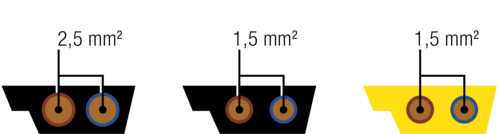

Clear separation of control signals from auxiliary power

Another advantage of the ASi profile cable is the possibility to clearly separate control signals from auxiliary power:

- The control signals are transmitted over the yellow profile cable.

- Two different profile cables (24 V and 48 V) are available for auxiliary power.

- The separation makes it possible to safely switch off the AUX supply in a targeted manner while the transmission of ASi signals for system monitoring continues without interruptions.

- The separation of control signals and auxiliary power can be useful, e.g. during setup or to provide passive safety.

- In contrast, when using a 4-wire round cable, it is only possible to switch off the AUX supply in a targeted manner with considerable effort.

Combined use of profile cables and round cables

Extremely simple connection technology, efficient power distribution, reduced cabling costs – the ASi cable is almost always the better alternative. However, there are a few applications where the flat profile cable cannot be used, e.g. if protection class IP69K must be achieved, as in the food industry, where round cables are more suitable.

For scenarios where a round cable is to be used, Bihl+Wiedemann offers modules with ASi connection via M12. The new ASi-5 modules are all available as M12 variants. Almost any standard round cable can be used.

A combined use of ASi both with profile cables and round cables is also possible. This is because Bihl+Wiedemann's passive distributors allow all sorts of junctions from profile cables to push-in terminals and connectors, such as M12/M8.

Profile cables for different usage scenarios

The ASi profile cable is available in different versions. The two-conductor yellow cable transmits data and power simultaneously. Different cable materials are available for different applications such as PUR, TPR, EPDM and rubber. If more power is required for a particular application (e.g. when using powerful motors), the black profile cable can also be used to supplement power requirements.

The cable used for AS-Interface is an unshielded, non-twisted, two-wire yellow flat cable that can be connected with reverse polarity protection. It serves simultaneously for the transmission of ASi communication and to supply power to field devices with low power requirements. A separate black flat cable is used to supply 24 VDC to customers with a higher power requirements, such as motors or valve terminals.

The sensors or actuators are usually connected via piercing technology. In this process, the insulation of the flat cable, which is profiled to protect against reverse polarity, is pierced during installation by means of two piercing pins, without the cable having to be prepared beforehand. In this way, slaves can be relocated or added directly to the cable at any time without major installation effort.

ASi end caps are used to protect the bare ends of the ASi or AUX profile cable against dust and humidity up to max. IP67 – for interference-free communication in the ASi circuit. They are available as left and right versions.

Many Bihl+Wiedemann slaves and active distributors do not generally require the use of end caps because the cable ends can be terminated in the base.

The total length of the ASi standard network is limited to 200 m for ASi-5 and 100 m for ASi-3. When determining the total length, all junctions must be included in the calculation. For example, with a combination of ASi repeaters and bus terminations, the maximum achievable distance between two slaves in an ASi-3 network is 1,000 m, if the master is appropriately positioned. No more than 2 repeaters (max. 2 connected in series) may be set between a slave and the master.

How to extend the ASi-3 cable to, e.g., 1,000 m

Extend the range of the ASi circuit flexibly and cost-effectively. Learn more about the possibilities of cable extension.

Installation technology in IP67 by Bihl+Wiedemann

Would you like to learn more about the ASi profile cable? Here you can read everything about the IP67 installation technology.

ASi cables are also available in our web shop

There you will find ASi profile cables, ASi round cables, ASi end caps and other accessories you need for cable installation.

LIP Bygningsartikler saves now 22% of the total cost on their conveyor modules thanks to an ASi solution from Bihl+Wiedemann. Each module and the complete system is connected through an ASi network with integrated safety from Bihl+Wiedemann. New conveyor modules can be added simply without additional wiring from the main PLC.

All the brewery’s processes including ASi Masters and motors are controlled via PROFINET by two Siemens PLCs. All the tanks, kettles and plant components can be mutually connected by means of a system of 744 pneumatically activated process valves – controlled by eight ASi Masters from Bihl+Wiedemann. The ASi network also links together instruments and sensors that record the process data from each fermentation tank, such as the pressure, level and temperature.

![[Translate to Englisch:] Verkabelungskosten [Translate to Englisch:] Verkabelungskosten](/fileadmin/_processed_/1/8/csm_BW_Icon_Verkabelungskosten_f7272e8eaa.png)