Drive solutions for SEW EURODRIVE

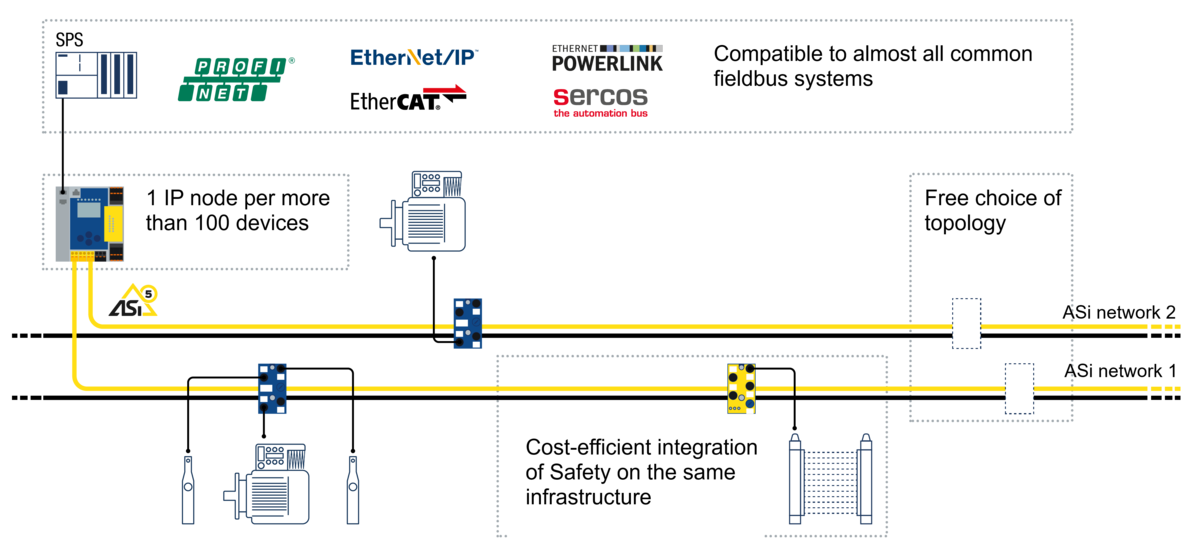

On this page, we present our ASi-3 and ASi-5 drive solutions for SEW. All modules are plug-and-play solutions with pin assignments adapted to the respective Lenze drive. We currently provide modules for the following drives:

- SEW MOVIMOT®

- SEW MOVI-SWITCH®

- SEW MOVI-C®

Please contact us if the drive you are looking for is not listed here. Here you will find detailed information about the advantages of our AS-Interface drive solutions.

Here you will find the product overview of our drive solutions for SEW EURODRIVE.

ASi-5 and ASi-3 Module for SEW MOVIMOT®

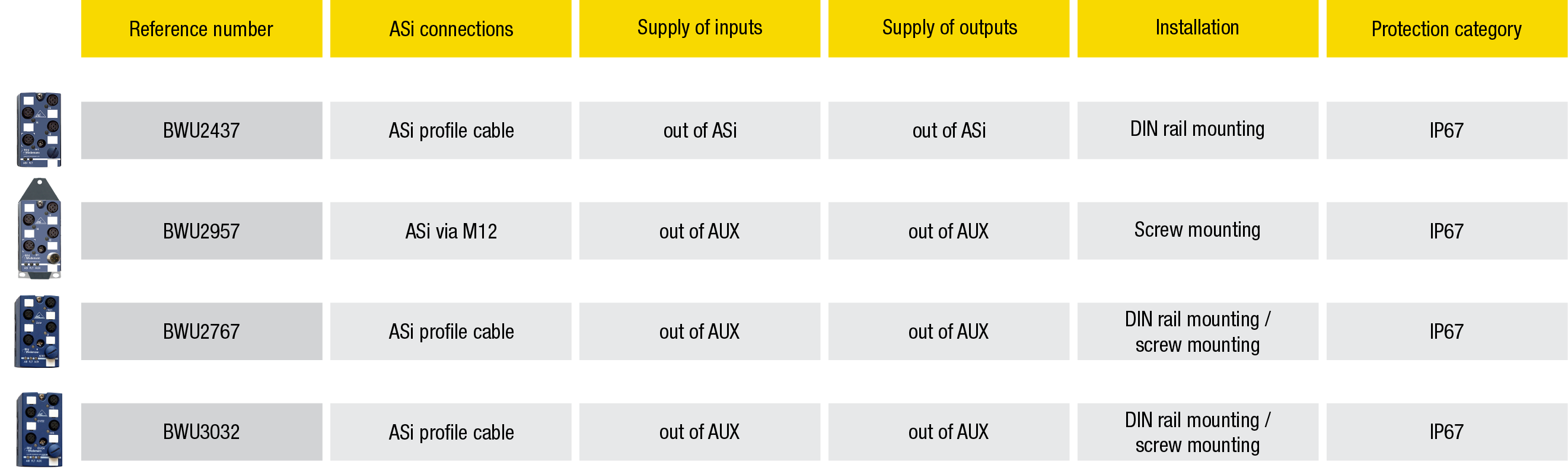

Functions such as start/stop, left-right run, or open/close can be implemented in the simplest and most cost-effective way with our ASi-3 modules. In our product overview, you will find the ASi-3 module for SEW MOVIMOT, optionally for binary control or RS485 communication.

Complicated and static definition of ramps and speeds for process control is a thing of the past with the ASi-5 Motor Module for SEW MOVIMOT® (BWU4068). Thanks to ASi-5, they can be set cyclically and thus adjusted extremely quickly. Up to 3 x 16 bits of process output data are available for this purpose.

Your advantages at a glance

- One SEW MOVIMOT® can be controlled per module

- With ASi-5 cyclic data; compatible with SEW PROFINET image

- Additional inputs and outputs

- With ASi-5 analysis of the actual measured motor current (thanks to 3 x 16-bit process output data)

- Efficient wiring of 100 SEW MOVIMOT® on just one Ethernet node

- High protection class IP67

The ASi-5 Motor Module SEW MOVIMOT® (BWU4068) also provides 4 inputs / 2 outputs for optimal control of the transport system

Save valuable resources

With AS-Interface, you do not need expensive plugs or sockets and only a single cable. This significantly reduces assembly times and material costs. In addition, valuable resources such as copper or plastic, which are required to manufacture the components, can be saved on a large scale. And energy consumption during cable production is greatly reduced. There is also a positive environmental effect when it comes to disposal – less waste is produced.

ASi-5 Module for SEW MOVI-C®

Our ASi-5 Motor Module (BWU4718) is suitable for all inverters of the SEW MOVI-C® series.

Your advantages at a glance

- Very flat design

- Supply only from ASi, therefore no AUX necessary

- Communication via Modbus TCP

- Cyclic writing of speeds and ramps

- Detailed diagnostics, e.g., to detect an output short circuit or an overload of the sensor supply

ASi-5 Module for SEW MOVI-C® (BWU4718)

ASi-3 Module for SEW MOVI-SWITCH®

We provide numerous module variants for binary control of SEW motors – optionally supplied via ASi or AUX (24 V). You will find an overview in our product overview.

Solutions for drives from leading manufacturers

Bihl+Wiedemann offers a wide range of solutions for drives from many leading manufacturers – for motorized rollers (Interroll, Itoh Denki, RULMECA), DC motors (ebm-papst), and frequency inverters (SEW, NORD, Danfoss, Rockwell, Lenze, Bonfiglioli). Other manufacturers can also be integrated if necessary.