AS-Interface – forenkling af automatisering

Hvad er AS-Interface?

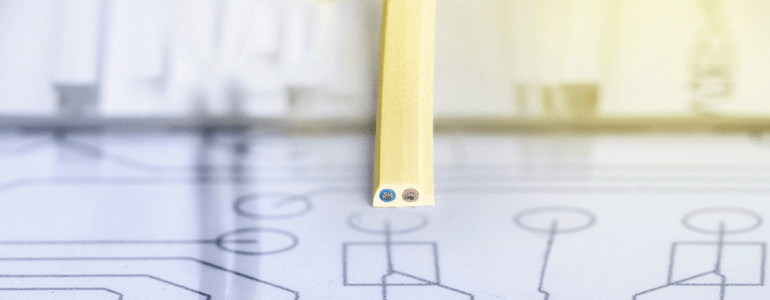

AS-Interface (ASi) er et globalt standardiseret feltbussystem for det første niveauaf automatisering. Forkortelsen ASi står for Actuator-Sensor Interface. ASi forbinder sensorer og aktuatorer med en controller via et enkelt to-leder profilkabel. Det gule ASi-kabel overfører strøm og data på samme tid. De primære fordele ved AS-Interface er blandt andet markant reduktion af ledningsføring, frit valg af topologi og omkostningseffektiv integration af sikkerhed på den samme infrastruktur.

Den nyeste ASi-5-generation kan nu håndtere større datamængder ved meget højere transmissionshastigheder, og den gør det muligt nemt at integrere intelligente sensorer såsom IO-Link.

Inhold

- Hvad er AS-Interface?

- ASi-5 – den nyeste generation af AS-Interface

- ASi Safety at Work

- Fordele ved AS-Interface

- Data og strøm i samme kabel

- AS-Interface-komponenter

- Lang række anvendelsesmuligheder for AS-Interface

- AS-Interface-software

- ASi-5/ASi-3-adresseprogrammeringsenhed – enkel til alle ASi-generationer

- Ofte stille spørgsmål om AS-Interface

Fordele ved AS-Interface

AS-Interface reducerer kablings- og monteringsomkostninger til et minimum og er ekstremt let af udvide eller eftermontere. ASi muliggør hurtig og fleksibel installation, i hvilken nye bus-enheder kan tilsluttes uden kompleks kabelkonfiguration.

Uafhængigt af system og producent

ASi-teknologien er kompatibel med næsten alle almindelige feltbussystemer. Det er lige meget, om det er PROFIBUS, PROFINET, CC-Link, EtherNet/IP osv., der anvendes på de højere niveauer.

Data og strøm i samme kabel

ASi forbinder modulet på det laveste procesniveau i automatiseringssystemer med hinanden. Det sædvanlige ledningsnet udskiftes med et enkelt elektrisk kabel. Både data og strøm overføres på dette ene kabel

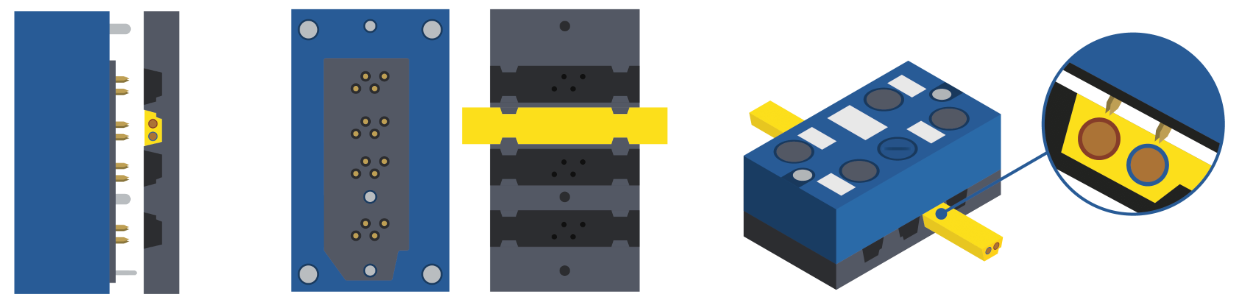

Ekstremt enkel installation, perfekt kontakt

Takket være ASi-perforeringsteknologi er det muligt at forbinde, udskifte, flytte eller tilføje moduler – f.eks. ASi-5-moduler med integreret IO-Link-master med 1, 2, 4 eller 8 porte. Fordele ved brug af profilkabel omfatter følgende:

Meget enkel forbindelsesteknologi: Moduler perforerer isoleringen af profilkablet. Mindst fire guldbelagte nåle perforerer lodret og pålideligt gennem gummibeviklingen ind i kablet, hvor to kabeltråde kommer i kontakt.

Maksimalt sikker kontakt: To nåle pr. tråd perforerer profilkablet redundant. Der er også garanti for lav kontaktmodstand.

Meget mindre besvær i forbindelse med installation: Der er intet behov for at overskære, skrælle eller terminere kablet, som det er tilfældet med runde kabler. Profilkablet tages simpelthen fra kabelrullen i den ønskede længde.

Zero Euro-tilslutningsomkostninger: Der kræves hverken formonterede kabler eller T-stykker til at forbinde moduler. Det giver uovertruffen eftermontering eller konvertering af systemer med hensyn til omkostninger.

AS-Interface-node

ASi-noder forbinder sensorer og aktuatorer til ASi-kablet. Der er en velegnet ASi-node til nærmest enhver tænkelig anvendelse.

AS-Interface-kabel

Det gule ASi-kabel forbinder ASi Master og overfører data og strøm på to ledere. Takket være ASi-perforeringsteknologi kan moduler nemt forbindes, udskiftes eller tilføjes.

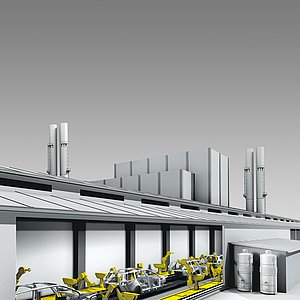

Flere og flere virksomheder på tværs af forskellige sektorer vælger nu ASi-løsninger fra Bihl+Wiedemann til at automatisere deres anlæg og systemer. Det åbne bussystem er særligt udbredt i fabriks- og industriel automatisering, transportbåndsløsninger, bygningsautomatisering og maskinindustri.

AS-Interface-software

Forskellige softwareprodukter er tilgængelige for enkel idriftsættelse, konfiguration og diagnosticering af ASi-netværk.

ASi-5/ASi-3-adresseprogrammeringsenhed – enkel til alle ASi-generationer

Med den kompakte ASi-5/ASi-3-adresseprogrammeringsenhed kan du nemt idriftsætte ASi-moduler af alle generationer – herunder ASi-5-moduler.

Understøtter ASi-moduler af alle generationer, inkl, ASi-5

Optimeret til simpel adressering uden ekstra mobile terminalenheder

Seks robust designede knapper for enkel betjening

Moderne OLED-farvedisplay

Standard USB-C-port til strømforsyning og som pc-interface

- Moderne strømlagring (superkondensatorer) til hurtig opladning og længere levetid

- Opladningstid: fuldt opladet på ca. 30 min, tilstrækkeligt til 120 læse/skrive-handlinger. Blot 10 min. opladning er tilstrækkelig til at tildele 70 ASi-adresser (f.eks. AB, enkelt, ASi-5)

- Klar til brug selv efter flere måneders opbevaring takket være lav selvafladning

ASi Safety at Work

Takket være ASi Safety at Work-konceptet har det været muligt uden problemer at integrere sikkerhedsrelaterede komponenter, som f.eks. sikre sensorer, aktuatorer og sikkerhedsmonitorer i næsten alle populære automatiseringssystemer. ASi Safety at Work er godkendt til anvendelser, der skal overholde sikkerhedskrav op til SIL3 i overensstemmelse med EN 61508 eller PLe i overensstemmelse med EN ISO 13 849-1:2006.

ASi-5 – den nyeste generation af AS-Interface

Den nye generation af AS-Interface muliggør nu markant hurtigere transmission af større mængder data og enkel integration af intelligente IO-Link-sensorer. ASi-5 muliggør f.eks. hurtig transmission af op til 32 bytes af IO-Link-procesdata via ASi. Dermed er mange ting, der tidligere ikke var mulige, nu blevet det med AS-Interface.

For mixed ASi-5/ASi-3 circuits, we recommend an additional ASi bus termination if the cable length is approx. 70 m or longer. The ASi bus termination can help improve the ASi-5 communication.

ASi-3 is a proven and stable technology with a wide range of available products. However, ASi-3 continues to be a future-proof technology whose possibilities are far from being exhausted. In the course of digitalization and Industry 4.0, it is now necessary to retrieve more and more data more quickly from the field level - in order to subsequently process them in higher-level instances. ASi-5 was developed for this requirement: The latest ASi generation offers a correspondingly high data bandwidth and short cycle times.

ASi-3 and ASi-5 are compatible with each other and complement each other optimally. Depending on the application or requirement, it must be checked individually which ASi technology is when the most appropriate or most economical. In practice, there will mostly be applications in which both ASi technologies are used. ASi-5 will therefore not replace ASi-3.

ASi-slutmuffer bruges til at beskytte de bare ender af ASi- eller AUX-profilkabel mod støv og fugtighed op til maks. IP67 – for interferensfri kommunikation i ASi-kredsløbet. De fås som venstre og højre versioner. Mange Bihl+Wiedemann noder og aktive fordelere kræver generelt brugen af slutmuffer, fordi kabelendere kan termineres i basen.

En ASi-ledningsstripper bruges til skrælning af ASi-kabler med en udvendig isolering af termoplastisk elastomer (TPE) eller polyurethan (PUR).

Sensorerne og aktuatorerne forbindes normalt ved hjælp af perforeringsteknologi. I denne proces perforeres det flade kabel, som profileres for at beskytte mod omvendt polaritet, under installationen af to perforeringsstifter, uden at kablet behøver at forberedes på forhånd. På denne måde kan noder omplaceres eller tilføjes direkte på kablet på et hvilket som helst tidspunkt uden større besvær med installation.

ASi-kablet er et uskærmet kabel med 2 kerner. Det overfører data og strøm, men muliggør også nem og omkostningseffektiv installation. Takket være perforeringsteknologien kan deltagere nemt installeres på det profilerede (og dermed beskyttet af omvendt polaritet) ASi-kabel – med perfekt kontakt og berettiget til beskyttelsesgrad IP67. Det er uden problemer muligt med en ekstra 24 V strømforsynings.

I konventionelt design er en separat ASi-strømforsyning (med integrerede afkoblingsspoler) påkrævet for strømforsyningen af hvert ASi-kredsløb. Med ASi-gateways og sikkerhedsmonitorer af versionen "1 strømforsyning, 1 gateway til 2 ASi-kredsløb, omkostningseffektive strømforsyninger" fra Bihl+Wiedemann er afkoblingsspolerne allerede indbygget i enhederne. Dette muliggør forsyningen af to ASi-kredsløb ved hjælp af én standard 30 V strømforsyning.

Med korte kabellængder kan selv en standard 24 V strømforsyning bruges. Dette er en optimal løsning til små og meget små systemer – dvs. til små maskiner med 3 til 15 ASi-noder og en maksimal kabellængde på 50 meter. Vi har en prisoverkommelig linje af ASi-gateways, der er optimeret til 24 V anvendelser.

Adressering af ASi-3-noder

Med ASi-3 er der 31 tilgængelige ASi-adresser, hvorved hver adresse kun kan tildeles én gang. Der kan skelnes mellem standardadressering og udvidet adressering. Adresseringstilstanden for ASi-deltagere bestemmes af producenten. Med standardadressering reserverer hver ASi-deltager en fuld adresse (1..31). Med udvidet adressering kan hver adresse reserveres af to ASi-deltagere (1A..31A, 1B..31B). Det er ikke muligt at adressere en ASi-node med standardadressering og en ASi-deltager med udvidet adressering på den samme adresse, f.eks. 3 og 3A eller 3B.

Adressering af ASi-5-noder

Med ASi-5 tildeles noderne et bestillingsnummer, der starter fra 1. Nummereringen foregår sekventielt.

ASi-noder er forbundet til ASi Master via et kabel. De bruges til at integrere sensorerne og aktuatorerne ind i ASi-netværket, uanset om det er inde i styretavlen eller i felten. Disse er forbundet med strømforsyningen og datakommunikation i ASi-netværket. Hver node tildeles til en unik adresse i netværket.

AS-Interface Master forbinder sensorer og aktuatorer med kontrol på højere niveau via ASi-modulerne. Med ASi Master, digitale og analoge data, der er blevet samlet decentralt af ASi-moduler, kan overføres til det højere niveau af kontrol gennem det respektive bussystem. Outputsignalerne for controlleren overføres derefter gennem ASi til aktuatorerne i felten.

Den samlede længde af ASi-standardnetværket er begrænset til 200 m for ASi-5 og 100 m for ASi-3. Alle overgange skal inkluderes i beregningen med henblik på fastlæggelse af den samlede længde. ASi-repeateren er et modul til kabelforlængelse. Det gør det muligt at øge kabellængde i et ASi-3-netværk op til 200 m. Områder med voldsomt forringet EMC kan dermed omgås. ASi-repeatere kan forårsage en vis forsinkelse i transmissionen af telegrammer.

Dette diagram viser den grundlæggende struktur.

Til blandede ASi-5/ASi-3-kredsløb anbefaler vi en ekstra ASi-busterminering, hvid kabellængden er ca. 70 m eller længere. ASi-bustermineringen kan bidrage til at forbedre ASi-5-kommunikationen.

Den samlede længde af ASi-standardnetværket er begrænset til 200 m for ASi-5 og 100 m for ASi-3. Ved fastlæggelse af den samlede længde skal alle overgange inkluderes i beregningen. ASi-busterminteringen er et omkostningseffektivt modul til forlængelse af kabellængden i et ASi-3-netværk på op til 200 m.

ASi-fordelere muliggør enkel tilslutning af forskellige sensorer og aktuatorer til ASi hvor som helst i felten over en M12 tilslutning. Der kræves aktive fordelere til sensorer og aktuatorer uden en integreret ASi-chip. Passive fordelere er velegnede til sensorer og aktuatorer med en integreret ASi-chip.

Hvordan kan ASi-3-kablet forlænges til f.eks. 1.000 m

Forlæng rækkevidden af ASi-kredsløbet fleksibelt og omkostningseffektivt. Få mere at vide om mulighederne for kabelforlængelse.

Tilslut alle sensorer og aktuatorer til ASi

Med hjælp af passive fordelere fra Bihl+Wiedemann kan alle sensorer integreres i et ASi-netværk.

ASi-moduler til brug under ekstreme betingelser

Her vil du finde en oversigt over vores moduler i EXTREME-produktkategorien til brug under ekstreme forhold.

ASi til en lang række anvendelser

Få mere at vide om hvordan du kan bruge AS-Interface inden for bygningsautomatisering eller materialehåndtering.

![[Translate to Dänemark (EN):] ASi Control Tools360 [Translate to Dänemark (EN):] ASi Control Tools360](/fileadmin/_processed_/1/a/csm_ASi_Control_Tools360_e5174e1859.png)

![[Translate to Dänemark (EN):] Diagnosesoftware [Translate to Dänemark (EN):] Diagnosesoftware](/fileadmin/_processed_/f/f/csm_ASi_Diagnose_Software_aa336fa78b.png)

![[Translate to Dänemark (EN):] ASi-5 [Translate to Dänemark (EN):] ASi-5](/fileadmin/_processed_/0/d/csm_ASi-5_16eb9cd0e9.png)