PLC Independent Safety Technology

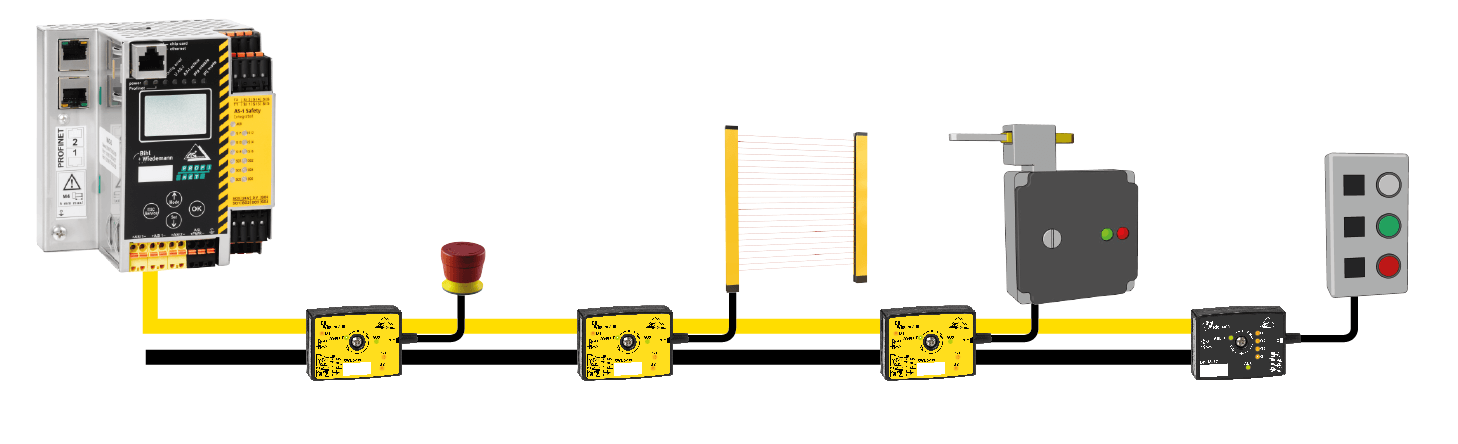

Our ASi systems are wired using a simple two-wire cable. It is easy to handle, avoids wiring mistakes and can be extended without difficulty. When it comes to higher-level systems, our safety and wiring technology can be used with any system and manufacturer and enables simple, fast and thus cost-effective commissioning.

One of the easiest installation concepts worldwide

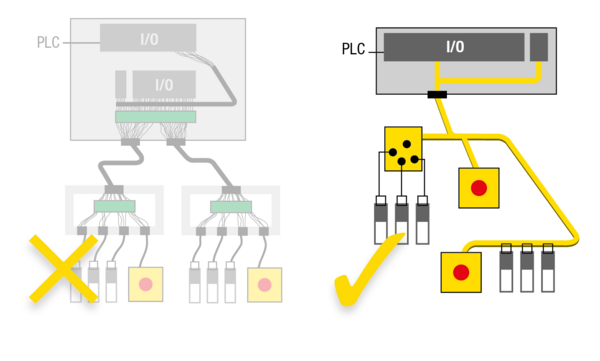

With conventional parallel wiring, at least four lines per E-STOP are necessary to achieve PLe, plus additional two lines for the lighting. In case of other safety sensors even more lines might be needed.

Bihl+Wiedemann devices, on the other hand, can send up to 62 safe signals plus the supply voltage over just one 2-conductor cable.

The result:

- Simplified wiring – cost savings

- Makes pre-assembly possible

- Much less error-prone than conventional parallel wiring

Wiring advantages

- Unshielded 2-conductor cable

- Data and power on the same cable

- Piercing technology makes installation simple

- Up to 62 safety devices

Free choice of topology

- Ring, star or linear structures

- Simple expansion

- AS-Interface features a clever piercing technology using a profiled cable. Simply insert the cable, tighten down – finished. Contact pins always penetrate the profiled cable vertically to guarantee perfect contacting.

- Optimal contacting provided by:

- Vertical contacting – contact security

- 4 or 6 pins per cable and 2 or 3 pins per conductor

Relieves the fieldbus

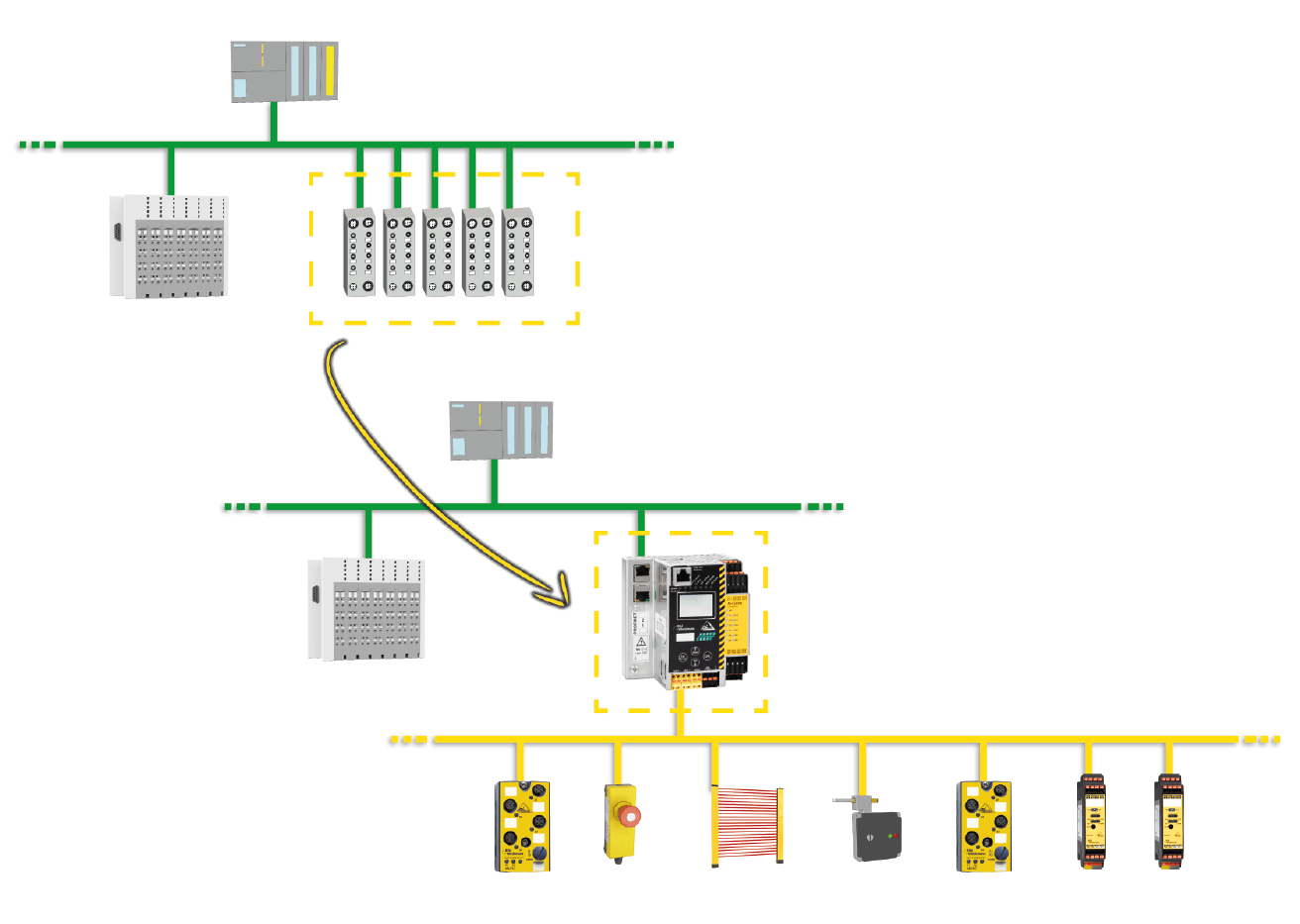

PLC independent safety technology relieves the higher level controller: instead of many individual fieldbus slaves only the Safety Gateway is connected to the fieldbus. It collects the safe sensors and actuators directly in the field and controls the actuators.

The use of Bihl+Wiedemann devices enables compact machinery design, since for example the space for decentralized control cabinet can be saved. Therefore the wiring effort required for doors with interlocks for example is significantly reduced. The piercing technology greatly reduces time and effort compared with expensive and cumbersome connector assembly.

- The field installation concept is always the same and reduces the fieldbus nodes – greater overview

- Safety Gateways eliminate the need for expensive measuring instruments thanks to the integrated measuring technology

- Increased performance of the fieldbus and simple expansion of the field modules

If for example multiple light barriers from manufacturer X are used for OSSDs in combination with safety doors with interlocks from manufacturer Y, conventional installation requires that all the components be wired in the control cabinet.

With the active distributors from Bihl+Wiedemann all sensors and actuators can be easily integrated into the network regardless of manufacturer:

- Safety switches

- Safety sensors

- Guard doors

- OSSDs

Save valuable resources

With AS-Interface, you do not need expensive plugs or sockets and only a single cable. This significantly reduces assembly times and material costs. In addition, valuable resources such as copper or plastic, which are required to manufacture the components, can be saved on a large scale. And energy consumption during cable production is greatly reduced. There is also a positive environmental effect when it comes to disposal – less waste is produced.

Functional safety

Learn how to seamlessly integrate safe sensors and actuators as well as safety monitors into all common automation systems with ASi Safety. Safe and unsafe signals can be transmitted on the same line.

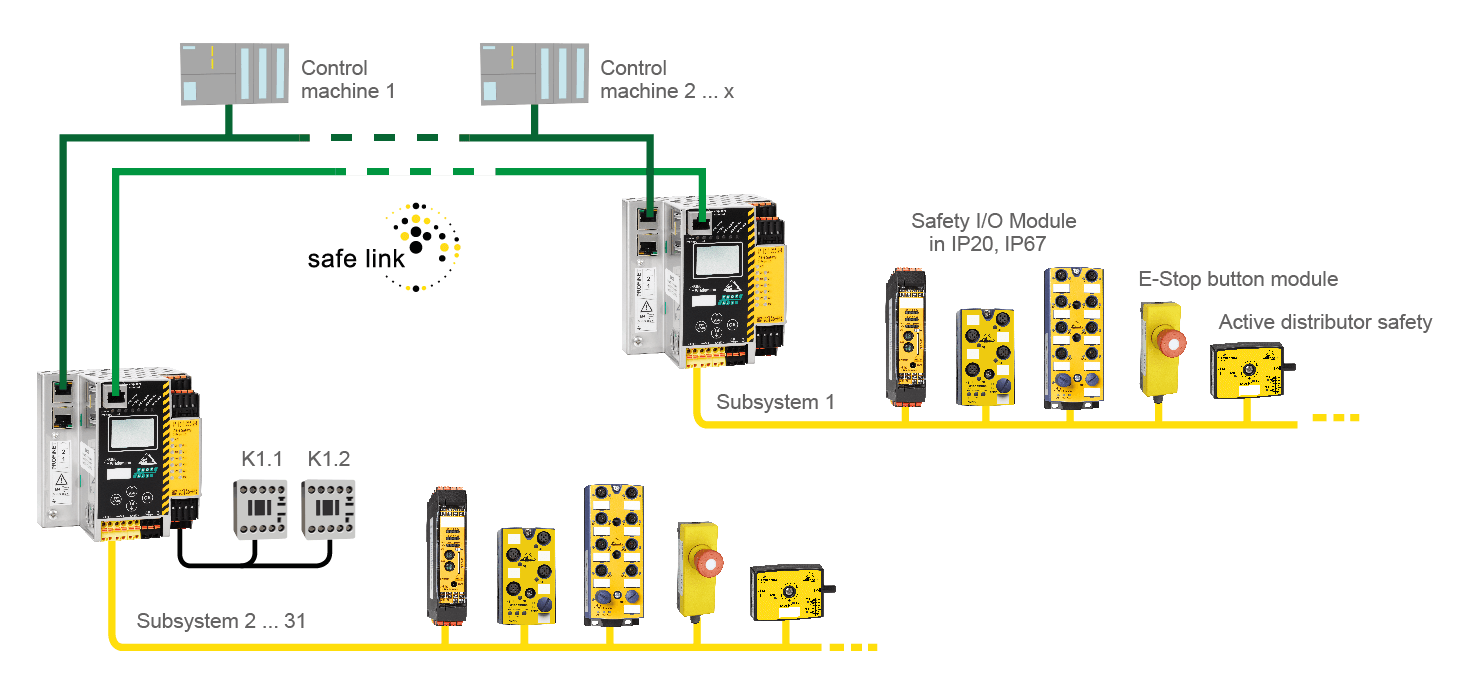

Safe Link

Find out how you can use our "Safe Link" safety technology solution to connect different system components easily and flexibly - even if different controlers are used.

Selection of Mode of Safe Operation

Read all about how our TÜV-certified device facilitates "selection of mode of sfae operation selection": A standard HMI allows you to safely select up to 5 different operating modes for a maximum of 6 plant sections – each with unique safety functions.

Speed monitoring

Discover an effective way to safely evaluate sensors or rotary encoders by means of our speed monitors. For example, a safe reduced speed can be achieved for setup operation.