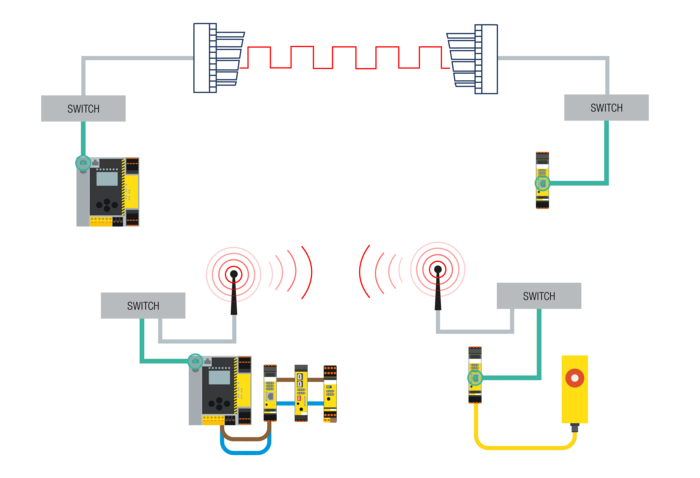

Safe Link

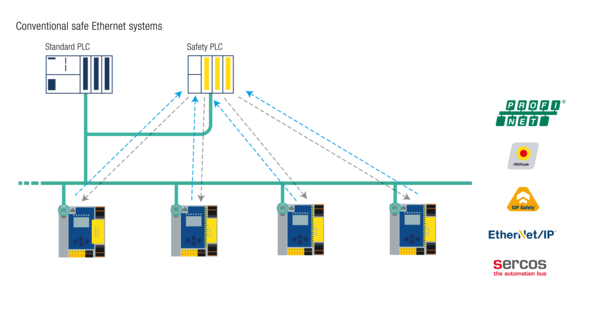

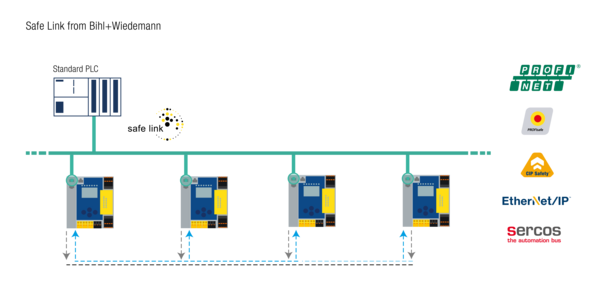

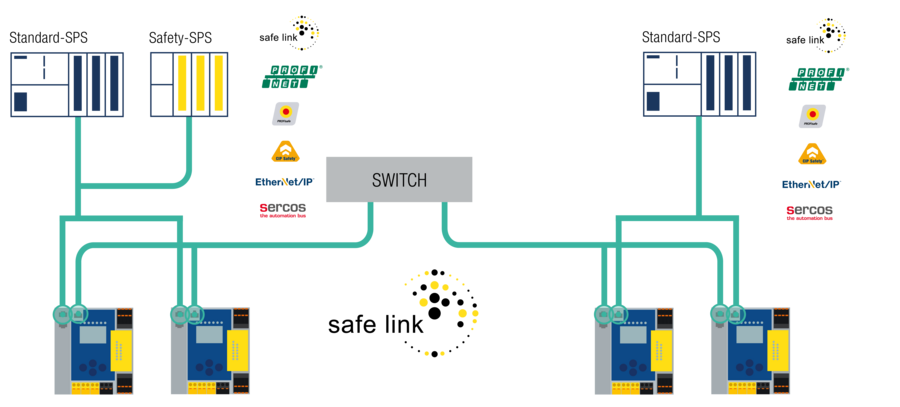

Both factory and process automation are showing a trend towards ever more complex, branched applications. The most efficient possible coupling of safe networks now becomes one of the special challenges in the area of safety.

A simple and cost effective solution

Bihl+Wiedemann has met this challenge with a simple and cost effective solution: Safe Link, i.e. safe coupling over the Ethernet interface of the ASi gateways with integrated safety monitor. In the maximum configuration this means up to 1922 safety two-channel input signals can be collected while controlling safety outputs either centrally or locally.

Couple up to 31 gateways

This approach enables up to 31 Safety Basic Monitors or Gateways with integrated Safety Monitor to be coupled to each other – without losing performance at any point and without the use of additional hardware.

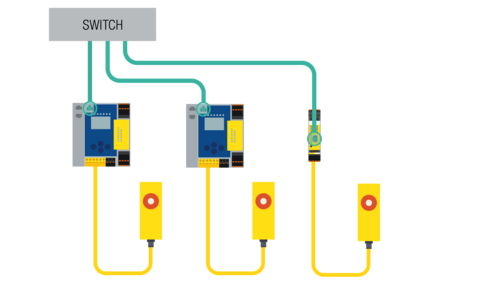

... optical data transmission / WLAN *

- Safe communication over optical data transmission (additionally required)

- Safe communication over WLAN networks (addional access points required)

- For example driverless transport systems, storage and retrieval systems and other mobile applications

* Optical data transceivers and industrial WLAN have to be ordered directly from the respective manufacturer. Devices with Safe Link from Bihl+Wiedemann are compatible with all commonly available brands and suppliers.

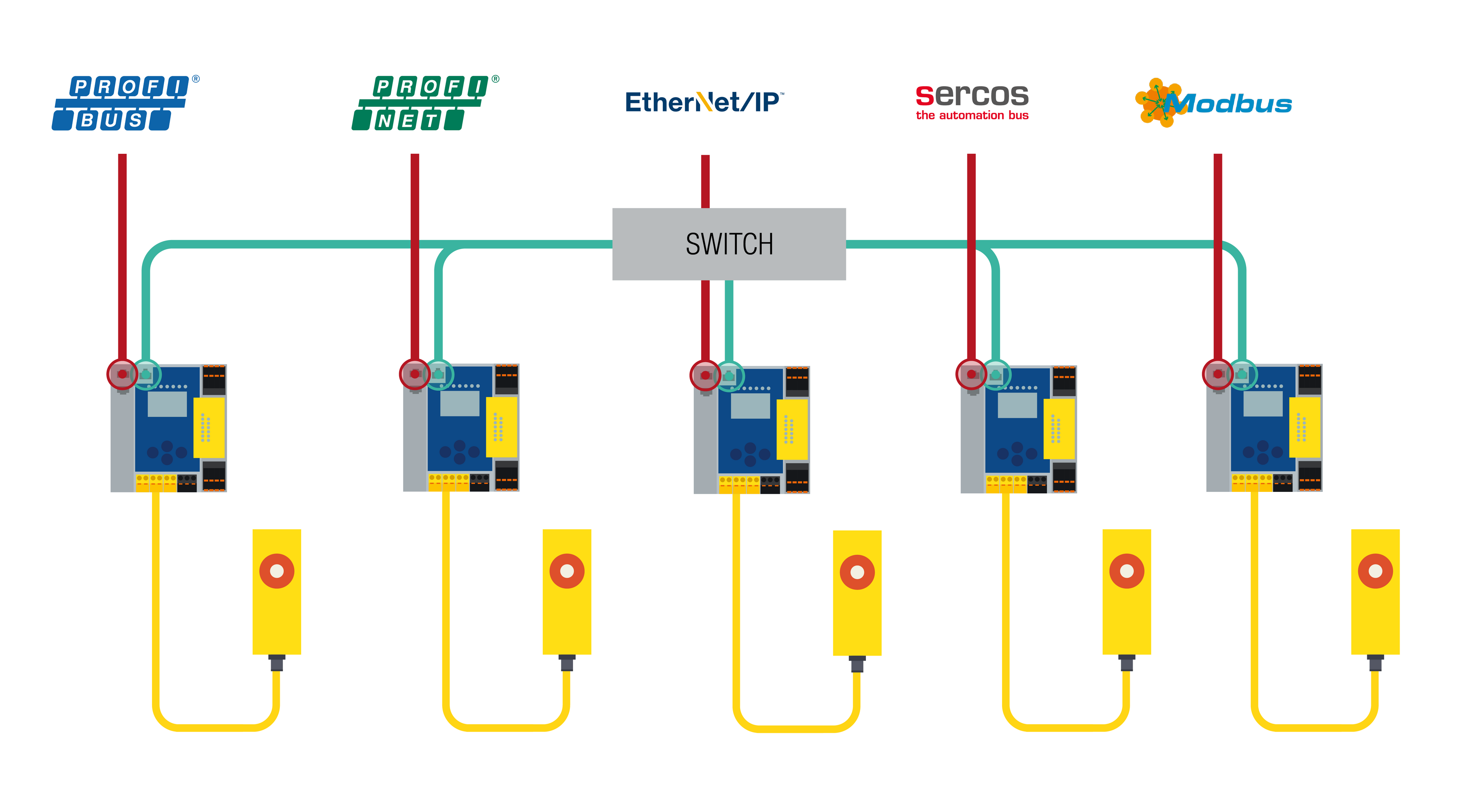

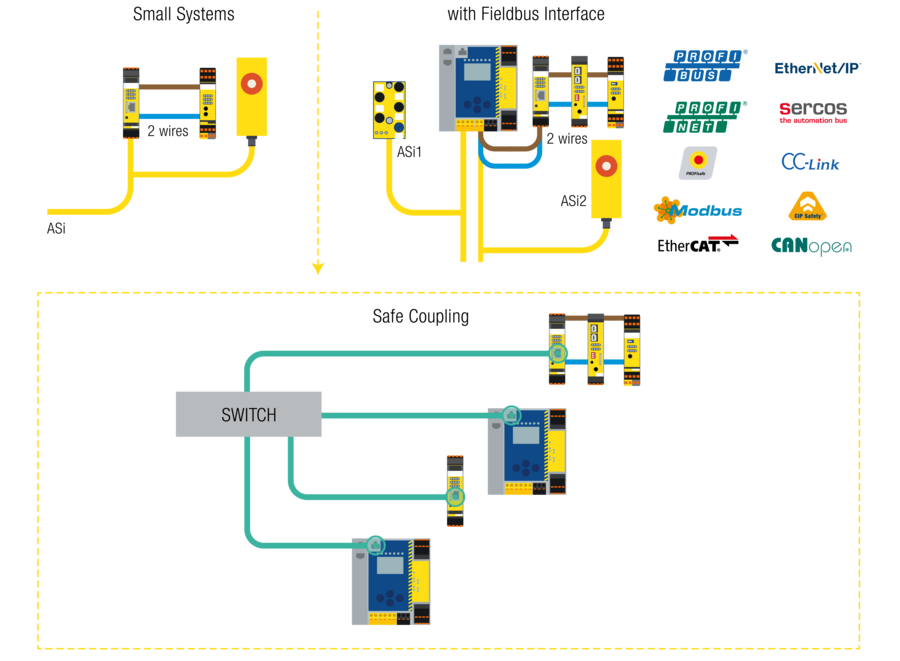

Safe coupling for any system size

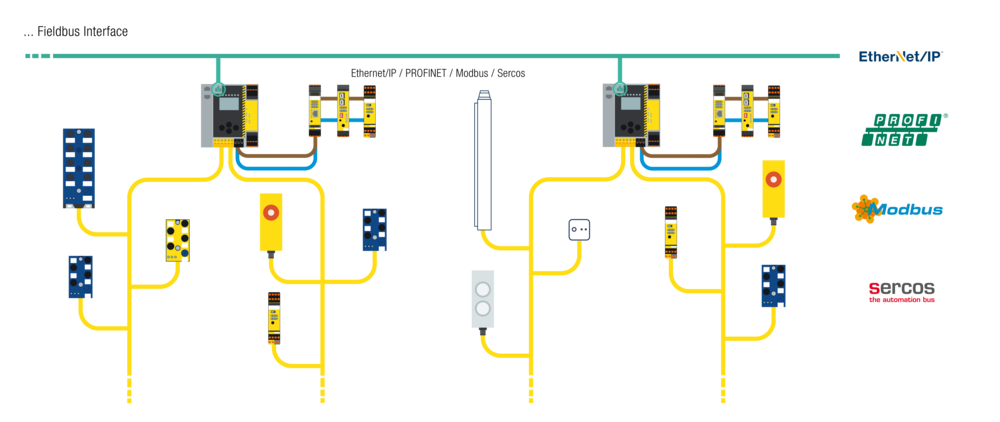

Safe Link can be used flexibly in small installations or via the fieldbus interface of the gateways of subsystems. Via the safe coupling, the subsystems can be combined into an overall system and be accessed without barriers.

Safe coupling of machines

Safe information exchange is possible between different system parts and also diverse field bus protocols via diagnostic interface.

31 devices can be coupled with each other

- Connections between the devices via Ethernet are usually already available

- Coupling via Ethernet-based fieldbus interface

- Coupling via Ethernet diagnostic interface

- Safe Link conforms to SIL3/Kat4/PLe

- Signals can be provided per device

- 31 x SIL3/Kat4/PLe

- “Each one hears all” principle

- Up to 1922 safety signals

Functional safety

Learn how to seamlessly integrate safe sensors and actuators as well as safety monitors into all common automation systems with ASi Safety. Safe and unsafe signals can be transmitted on the same line.

PLC independent safety technology

Discover the advantages of our safety and wiring technology, which is system and manufacturer-neutral. In this way, it enables simple, fast and thus cost-effective commissioning.

Muting

Discover how easy muting is with Bihl+Wiedemann's muting modules. All signals required for muting can be connected to a single module.

Selection of Mode of Safe Operation

Read all about how our TÜV-certified device facilitates "selection of mode of sfae operation selection": A standard HMI allows you to safely select up to 5 different operating modes for a maximum of 6 plant sections – each with unique safety functions.